Information injection-pump assembly

BOSCH

9 400 616 948

9400616948

ZEXEL

106671-7620

1066717620

MITSUBISHI

ME050826

me050826

Rating:

Service parts 106671-7620 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

ME059621

12.

Open Pre:MPa(Kqf/cm2)

21.6(220)

15.

NOZZLE SET

Include in #1:

106671-7620

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 400 616 948

9400616948

ZEXEL

106671-7620

1066717620

MITSUBISHI

ME050826

me050826

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131424-4620

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

4.8

4.75

4.85

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

11.7

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

132.5

129.5

135.5

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

C

Rack position

5+-0.5

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

14

11.4

16.6

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Injection quantity adjustment_03

Adjusting point

B

Rack position

6.3+-0.5

Pump speed

r/min

250

250

250

Average injection quantity

mm3/st.

14

11.4

16.6

Fixing the rack

*

Remarks

(check)

(check)

Timer adjustment

Pump speed

r/min

650--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

600

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

750

Advance angle

deg.

0.7

0.2

1.2

Timer adjustment_04

Pump speed

r/min

900

Advance angle

deg.

1.6

1.1

2.1

Timer adjustment_05

Pump speed

r/min

-

Advance angle

deg.

3

2.5

3.5

Remarks

Measure the actual speed, stop

Measure the actual speed, stop

Test data Ex:

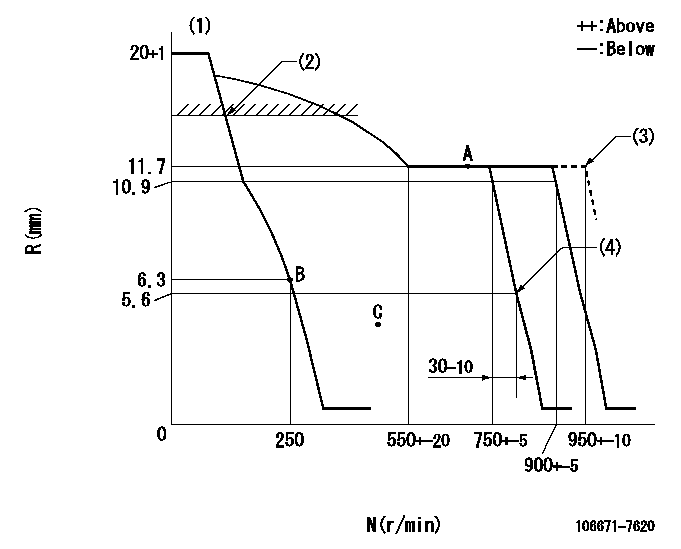

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)RACK LIMIT: RAL

(3)At shipping

(4)Idle sub spring setting: L1.

----------

K=14 RAL=15+0.2mm L1=5.5+-0.1mm

----------

----------

K=14 RAL=15+0.2mm L1=5.5+-0.1mm

----------

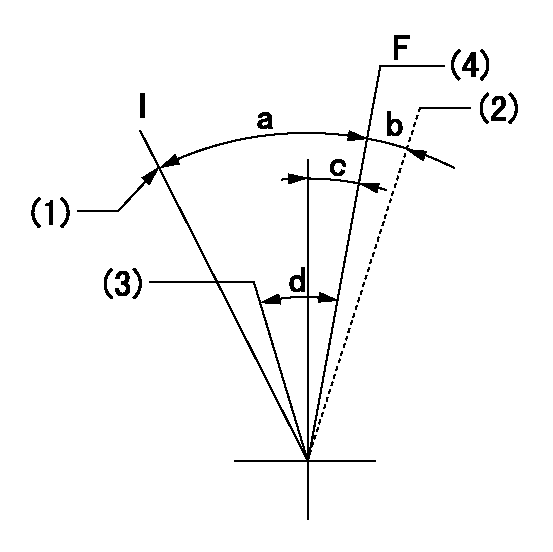

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

(2)At shipping

(3)Pump speed = aa

(4)Pump speed = bb

----------

aa=750r/min bb=900r/min

----------

a=28deg+-5deg b=(2deg) c=2deg+-5deg d=6deg+-5deg

----------

aa=750r/min bb=900r/min

----------

a=28deg+-5deg b=(2deg) c=2deg+-5deg d=6deg+-5deg

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=19deg+-5deg b=53deg+-5deg

----------

----------

a=19deg+-5deg b=53deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(7deg)

----------

----------

a=(7deg)

Information:

Table 1

New Parts List

Item Qty Part Description

1 1 472-6522 Bracket As

473-5117 Bracket As

473-5118 Bracket As

Illustration 1 g06066445

Typical example

Illustration 2 g06066447New 472-6522 Bracket As replaces the former 443-2031 Bracket As in the 443-2026 Platform Enclosure Gp.New 473-5117 Bracket As replaces the former 435-3848 Bracket As in the 431-4229 Platform Enclosure Gp.New 473-5118 Bracket As replaces the former 437-7140 Bracket As in the 437-7780 Platform Enclosure Gp.New 472-6522 Bracket As, 473-5117 Bracket As, and 473-5118 Bracket As are adaptable to machines and effective in production with machines that are listed in Table 2.

Table 2

Sales Model Adaptable to Machines Effective in Production with Machines

950M S/N:EMB1-1123 S/N:EMB1124-UP

S/N:FTR1-900 S/N:FTR901-UP

962M S/N:EJB1-290 S/N:EJB291-UP

S/N:F2T1-500 S/N:F2T501-UP

966M S/N:DYC1-1000 S/N:DYC1001-UP

S/N:KJP1-1600 S/N:KJP1601-UP

966M Series XE S/N:P6C1-900 S/N:P6C901-UP

972M S/N:A8P1-900 S/N:A8P901-UP

S/N:JPR1-800 S/N:JPR801-UP

972M Series XE S/N:EDW1-700 S/N:EDW701-UP

980M S/N:KRS1-1246 S/N:KRS1247-UP

S/N:N8T1-534 S/N:N8T535-UP

982M S/N:F9A1-275 S/N:F9A276-UP

S/N:K1Y1-613 S/N:K1Y614-UP