Information injection-pump assembly

ZEXEL

106671-7610

1066717610

Rating:

Cross reference number

ZEXEL

106671-7610

1066717610

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131424-4620

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

4.8

4.75

4.85

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

-

Rack position

9.4

Pump speed

r/min

700

700

700

Each cylinder's injection qty

mm3/st.

144

140.5

147.5

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

F

Rack position

5+-0.5

Pump speed

r/min

500

500

500

Each cylinder's injection qty

mm3/st.

16.5

14

19

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(9.4)

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

144

143

145

Basic

*

Fixing the lever

*

Boost pressure

kPa

28

28

Boost pressure

mmHg

210

210

Injection quantity adjustment_04

Adjusting point

B

Rack position

9.65+-0.

5

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

161

159

163

Fixing the lever

*

Boost pressure

kPa

28

28

Boost pressure

mmHg

210

210

Injection quantity adjustment_05

Adjusting point

C

Rack position

5.7+-0.5

Pump speed

r/min

225

225

225

Each cylinder's injection qty

mm3/st.

16.5

14

19

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Remarks

(check)

(check)

Injection quantity adjustment_06

Adjusting point

D

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

115

75

155

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_07

Adjusting point

G

Rack position

9.9+-0.5

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

153

151

155

Fixing the lever

*

Boost pressure

kPa

28

28

Boost pressure

mmHg

210

210

Boost compensator adjustment

Pump speed

r/min

600

600

600

Rack position

8.2

Boost pressure

kPa

4

4

4

Boost pressure

mmHg

30

30

30

Boost compensator adjustment_02

Pump speed

r/min

600

600

600

Rack position

8.7

Boost pressure

kPa

8

6.7

9.3

Boost pressure

mmHg

60

50

70

Boost compensator adjustment_03

Pump speed

r/min

600

600

600

Rack position

R1(9.4)

Boost pressure

kPa

14.7

14.7

14.7

Boost pressure

mmHg

110

110

110

Test data Ex:

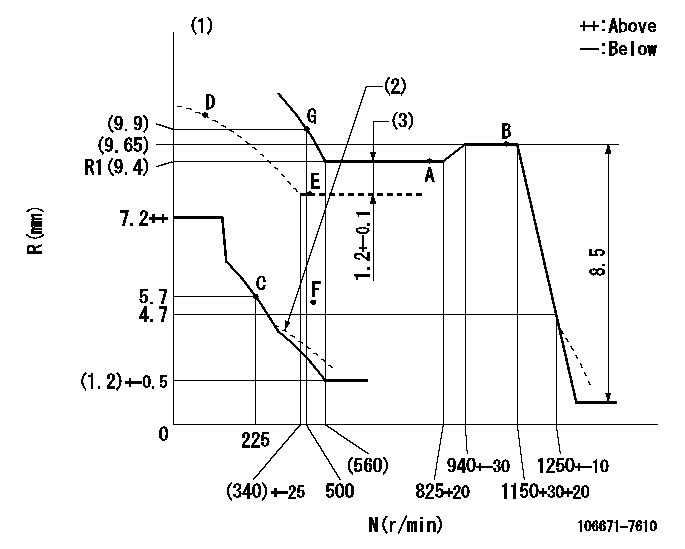

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Boost compensator cancel stroke: BSL

(2)Damper spring setting: DL

(3)Boost compensator stroke

----------

BSL=1.6mm DL=4.5-0.2mm

----------

----------

BSL=1.6mm DL=4.5-0.2mm

----------

Timer adjustment

(1)Adjusting range

(2)Step response time

(N): Speed of the pump

(L): Load

(theta) Advance angle

(Srd1) Step response time 1

(Srd2) Step response time 2

1. Adjusting conditions for the variable timer

(1)Adjust the clearance between the pickup and the protrusion to L.

----------

L=1-0.2mm N2=800r/min C2=(8.8deg) t1=2.5--sec. t2=2.5--sec.

----------

N1=750++r/min P1=0kPa(0kgf/cm2) P2=392kPa(4kgf/cm2) C1=8.8+-0.3deg R01=0/4load R02=4/4load

----------

L=1-0.2mm N2=800r/min C2=(8.8deg) t1=2.5--sec. t2=2.5--sec.

----------

N1=750++r/min P1=0kPa(0kgf/cm2) P2=392kPa(4kgf/cm2) C1=8.8+-0.3deg R01=0/4load R02=4/4load

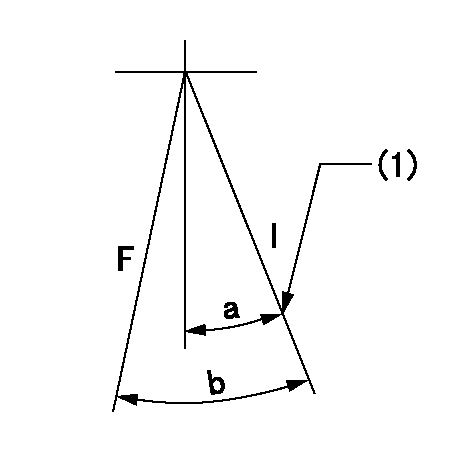

Speed control lever angle

F:Full speed

----------

----------

a=16.5deg+-5deg

----------

----------

a=16.5deg+-5deg

0000000901

F:Full load

I:Idle

(1)Stopper bolt setting

----------

----------

a=28deg+-5deg b=(30deg)+-3deg

----------

----------

a=28deg+-5deg b=(30deg)+-3deg

Stop lever angle

N:Engine manufacturer's normal use

S:Stop the pump.

(1)Rack position = aa

(2)Stopper bolt setting

(3)Rack position bb

(4)Free (at shipping)

----------

aa=4.1-0.5mm bb=13.3mm

----------

a=26deg+-5deg b=(38deg) c=0deg+7deg-5deg

----------

aa=4.1-0.5mm bb=13.3mm

----------

a=26deg+-5deg b=(38deg) c=0deg+7deg-5deg

0000001501 RACK SENSOR

V1:Supply voltage

V2f:Full side output voltage

V2i:Idle side output voltage

(A) Black

(B) Yellow

(C) Red

(D) Trimmer

(E): Shaft

(F) Nut

(G) Load lever

1. Load sensor adjustment

(1)Connect as shown in the above diagram and apply supply voltage V1.

(2)Hold the load lever (G) against the full side.

(3)Turn the shaft so that the voltage between (A) and (B) is V2.

(4)Hold the load lever (G) against the idle side.

(5)Adjust (D) so that the voltage between (A) and (B) is V2i.

(6)Repeat the above adjustments.

(7)Tighten the nut (F) at the point satisfying the standards.

(8)Hold the load lever against the full side stopper and the idle side stopper.

(9)At this time, confirm that the full side output voltage is V2f and the idle side output voltage is V2i.

----------

V1= 5+-0.02V V2f=0.15+0.03V V2i=2.35-0.03V

----------

----------

V1= 5+-0.02V V2f=0.15+0.03V V2i=2.35-0.03V

----------

0000001601 MICRO SWITCH

Adjustment of the micro-switch

Adjust the bolt to obtain the following lever position when the micro-switch is ON.

(1)Speed N1

(2)Rack position Ra

----------

N1=325+-5r/min Ra=5.4mm

----------

----------

N1=325+-5r/min Ra=5.4mm

----------

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(7deg)

----------

----------

a=(7deg)

Information:

Remove the smaller hex nut (15.88 mm) (10) from the new 396-0380 Coupling along with ferrule (11) and ferrule (12). Orient the parts as shown in Illustration 3. Loosely install the parts onto the existing half of the 396-0380 Coupling on the engine. Refer to Illustration 4. Do not tighten the nut at this time.Note: Failure to orient the ferrules as shown in Illustration 3 will result in leakage and the need to replace the parts.

Illustration 5 g06054145

(14) 485-1630 Hose As

Push the quick-connect end of hose (14) onto the fuel pump drain line tube. An audible click should be heard and the fuel line should stay attached when gently pulled.

Illustration 6 g06054154

(14) 485-1630 Hose As

(15) 5P-9085 Clip

Place two new clips (15) onto hose (14) as shown in Illustration 6.

Illustration 7 g06054168

(14) 485-1630 Hose As

(16) 6V-8455 Bolt

(17) 8T-4121 Hard Washer

Illustration 8 g06054107

Lift the tube end of hose (14) and place the hose into the connector nut as shown in Illustration 8. Hand-tighten the nut, only.

Loosely secure the two clips with new bolts (16) and washers (17).

Illustration 9 g06054123

Mark the tube connector nut at the 6 o'clock position.

Illustration 10 g06054127

While holding the lower fitting stationary with another wrench and pushing the tube downward, tighten the nut one and one-quarter revolutions until the mark is at the 9 o'clock position. Refer to Illustrations 8,9, and 10.

Once the fitting is tightened, tighten bolts (16) securing the two clips (Illustration 7). Tighten the vertically mounted bolt first, then tighten the horizontally mounted bolt. Tighten each bolt to 25 2 N m (18.5 1.5 lb ft).

Reuse the existing hardware and reinstall the secondary fuel filter base. Tighten the bolts to 45 5 N m (33 4 lb ft). Hold the filter base vertical while tightening the bolts.

Illustration 11 g06054224

(18) Banjo bolt

(19) Spigot

(20) Front port

(21) Rear port

(22) 485-1627 Hose As

(25) 228-6046 Connector

(26) 228-7100 O-Ring Seal

Remove banjo bolt (18) and spigot (19). Retain one of the washers. Replace the banjo bolt with the new 8T-4191 Bolt and the retained washer. Tighten the bolt to 22 2 N m (16 1.5 lb ft).

Illustration 12 g06054327

Hose release orientation

(22) 485-1627 Hose As

Install hose (22) on the pump. It is important to note that the plastic release must be rotated so the flat is aligned with the body of the pump. Refer to Illustration 12.

Install connector (25) and O-Ring (26) at rear port (21). Tighten the connector to 30 2 N m (22 1.5 lb ft).

Install the new 228-7089 O-Ring Seal onto the connector. Then, install the other end of hose (22) to the connector. Holding the hose angle at approximately 5 degrees clockwise from vertical down, tighten the hose to 30 2 N m (22 1.5 lb ft).

Install a new 228-7100 O-Ring Seal onto the 8T-7487 Connector and install at front port (20). Tighten the connector to 30 2 N m (22 1.5 lb ft).

Install the new 228-7088 O-Ring Seal on the 8T-7487 Connector.

Illustration 13 g06054360

Connect braided hose (3) to