Information injection-pump assembly

ZEXEL

106671-7600

1066717600

Rating:

Cross reference number

ZEXEL

106671-7600

1066717600

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131424-4620

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

4.8

4.75

4.85

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

-

Rack position

9.4

Pump speed

r/min

700

700

700

Each cylinder's injection qty

mm3/st.

144

140.5

147.5

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

F

Rack position

5+-0.5

Pump speed

r/min

500

500

500

Each cylinder's injection qty

mm3/st.

16.5

14.2

18.8

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(9.4)

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

144

143

145

Basic

*

Fixing the lever

*

Boost pressure

kPa

43.3

43.3

Boost pressure

mmHg

325

325

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1(9.4)

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

152.8

149.6

156

Difference in delivery

mm3/st.

6.4

6.4

6.4

Fixing the lever

*

Boost pressure

kPa

43.3

43.3

Boost pressure

mmHg

325

325

Injection quantity adjustment_05

Adjusting point

D

Rack position

9.3

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

139.5

135.5

143.5

Fixing the lever

*

Boost pressure

kPa

28

28

28

Boost pressure

mmHg

210

210

210

Injection quantity adjustment_06

Adjusting point

C

Rack position

5.7+-0.5

Pump speed

r/min

225

225

225

Each cylinder's injection qty

mm3/st.

16.5

14

19

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Remarks

(check)

(check)

Injection quantity adjustment_07

Adjusting point

E

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

125

105

145

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Boost compensator adjustment

Pump speed

r/min

600

600

600

Rack position

7.9

Boost pressure

kPa

3.3

3.3

3.3

Boost pressure

mmHg

25

25

25

Boost compensator adjustment_02

Pump speed

r/min

600

600

600

Rack position

8.55

Boost pressure

kPa

14.7

8

21.4

Boost pressure

mmHg

110

60

160

Boost compensator adjustment_03

Pump speed

r/min

600

600

600

Rack position

9.3

Boost pressure

kPa

28

26.7

29.3

Boost pressure

mmHg

210

200

220

Boost compensator adjustment_04

Pump speed

r/min

600

600

600

Rack position

R1(9.4)

Boost pressure

kPa

30

30

30

Boost pressure

mmHg

225

225

225

Timer adjustment

Pump speed

r/min

450--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

400

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

800

Advance angle

deg.

3

2.5

3.5

Remarks

Finish

Finish

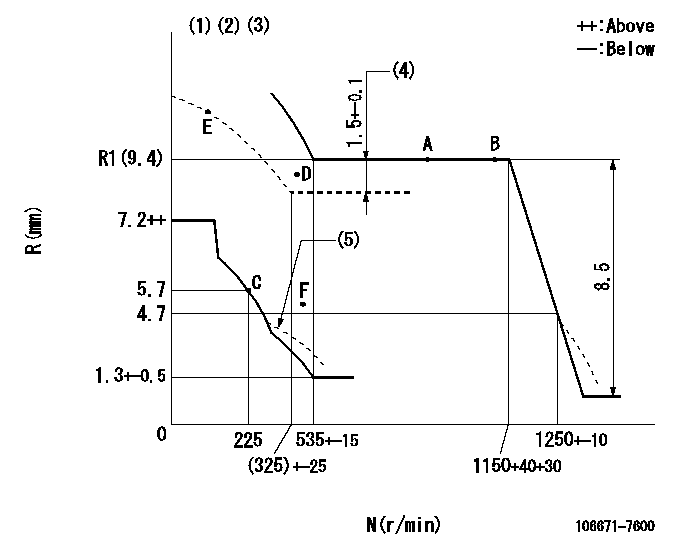

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Lever ratio: RT

(2)Target shim dimension: TH

(3)Boost compensator cancel stroke: BSL

(4)Boost compensator stroke

(5)Damper spring setting: DL

----------

RT=1 TH=1.8mm BSL=2.2mm DL=4.5-0.2mm

----------

----------

RT=1 TH=1.8mm BSL=2.2mm DL=4.5-0.2mm

----------

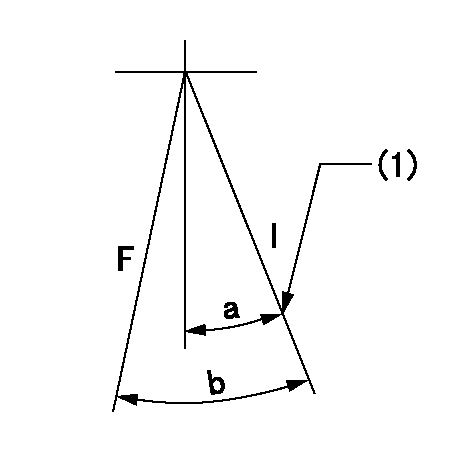

Speed control lever angle

F:Full speed

----------

----------

a=18deg+-5deg

----------

----------

a=18deg+-5deg

0000000901

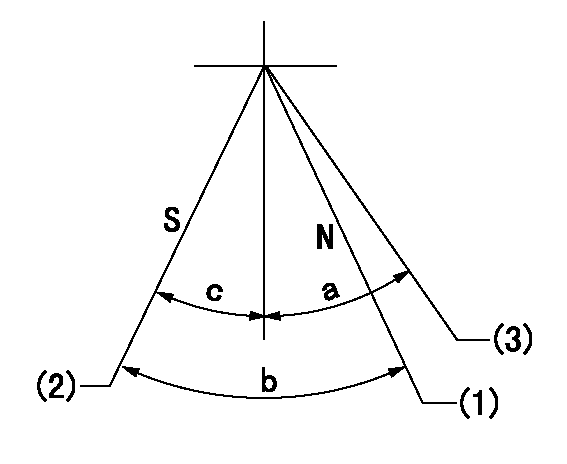

F:Full load

I:Idle

(1)Stopper bolt setting

----------

----------

a=28deg+-5deg b=30deg+-3deg

----------

----------

a=28deg+-5deg b=30deg+-3deg

Stop lever angle

N:Engine manufacturer's normal use

S:Stop the pump.

(1)Rack position = aa

(2)Rack position = bb, set the stopper bolt.

(3)Free (at shipping)

----------

aa=13.3mm bb=4.1-0.5mm

----------

a=(38deg) b=26deg+-5deg c=0deg+7deg-5deg

----------

aa=13.3mm bb=4.1-0.5mm

----------

a=(38deg) b=26deg+-5deg c=0deg+7deg-5deg

0000001501 MICRO SWITCH

Adjustment of the micro-switch

Adjust the bolt to obtain the following lever position when the micro-switch is ON.

(1)Speed N1

(2)Rack position Ra

----------

N1=325+-5r/min Ra=5.4mm

----------

----------

N1=325+-5r/min Ra=5.4mm

----------

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(7deg)

----------

----------

a=(7deg)

Information:

Introduction

The problem that is identified below does not have a known permanent solution. Until a permanent solution is known, use the solution that is identified below.Problem

There have been instances of event code E930 occurring on certain C7.1 engines. Caterpillar is investigating the root cause of these fault codes and to support the investigation, Caterpillar requests that the following procedure is conducted.Solution

Conduct the following steps and ensure that the "TIB Check List" is completed and submitted to the following email address:venters_phil

Download the "Product Status Report" from the engine ECM.

Record the Clean Emissions Module (CEM) serial number from the data plate on the CEM unit.

Conduct the troubleshooting procedure in Troubleshooting, DEF Pressure Is High.

Download the "Product Status Report" from the engine ECM again.

Conduct an Aftertreatment SCR System Dosing – Test. Refer to Systems Operation, Testing and Adjusting, Aftertreatment SCR System Dosing – Test.Note: When removing the Diesel Exhaust Fluid (DEF) injector from the outlet of the Diesel Particulate Filter (DPF), make sure that photographs of any deposits on the injector tip and within the DEF injector port on the Clean Emissions Module (CEM) are taken and documented.

A photograph of the part number and serial number on the side of the DEF injector and mounting must be taken and documented.

Make sure that the measured amount of DEF injected during the test is documented on the "TIB Check List".

If the injector dosing is within 100 mL (3.4 oz) to 130 mL (4.4 oz), reinstall the DEF injector assembly. Refer to Disassembly and Assembly, DEF Injector and Mounting - Remove and Install for the correct procedure.

If the injector is not within 100 mL (3.4 oz) to 130 mL (4.4 oz), replace the DEF injector assembly. Refer to Disassembly and Assembly, DEF Injector and Mounting - Remove and Install for the correct procedure.

Ensure that the latest flash file is installed in the Engine ECM.

Use the electronic service tool to perform the "Aftertreatment Recovery Procedure".

Conduct an "Aftertreatment System Functional Test". This test is located within the electronic service tool, “Diagnostics" on the main menu, then click "Diagnostic Tests".

If test is successful and no codes are present, return the machine to service.

If test is unsuccessful, contact the Dealer Solutions Network (DSN).

Submit the following items to the email address below:

"TIB Check List"

"Product Status Reports"

DEF injector deposits photographs

CEM deposit photographs

DEF injector part number and serial number photographventers_phil

Table 1

TIB Check List

Step Number Completed (Yes / No) Results / Comments

Step 1. Download "Product Status Report" (PSR) from the engine ECM and send to the email address in the instructions.

Step 2. Record the CEM serial number.

Step 3. "DEF Pressure Is High" troubleshooting.

A. Check the DEF lines for a restriction.

B. Replace the pressure and backflow fittings.

C. Check for a restriction in the DEF pump.

D. Perform an "Aftertreatment System Functional Test".

Step 4. Download "Product Status Report" (PSR) from the engine ECM and send to the email address in the instructions.

Step 5. Aftertreatment SCR System Dosing Test.

A. DEF Injector deposit photograph taken. CEM deposit photograph taken.

Step 6. DEF Injector part number and serial number

The problem that is identified below does not have a known permanent solution. Until a permanent solution is known, use the solution that is identified below.Problem

There have been instances of event code E930 occurring on certain C7.1 engines. Caterpillar is investigating the root cause of these fault codes and to support the investigation, Caterpillar requests that the following procedure is conducted.Solution

Conduct the following steps and ensure that the "TIB Check List" is completed and submitted to the following email address:venters_phil

Download the "Product Status Report" from the engine ECM.

Record the Clean Emissions Module (CEM) serial number from the data plate on the CEM unit.

Conduct the troubleshooting procedure in Troubleshooting, DEF Pressure Is High.

Download the "Product Status Report" from the engine ECM again.

Conduct an Aftertreatment SCR System Dosing – Test. Refer to Systems Operation, Testing and Adjusting, Aftertreatment SCR System Dosing – Test.Note: When removing the Diesel Exhaust Fluid (DEF) injector from the outlet of the Diesel Particulate Filter (DPF), make sure that photographs of any deposits on the injector tip and within the DEF injector port on the Clean Emissions Module (CEM) are taken and documented.

A photograph of the part number and serial number on the side of the DEF injector and mounting must be taken and documented.

Make sure that the measured amount of DEF injected during the test is documented on the "TIB Check List".

If the injector dosing is within 100 mL (3.4 oz) to 130 mL (4.4 oz), reinstall the DEF injector assembly. Refer to Disassembly and Assembly, DEF Injector and Mounting - Remove and Install for the correct procedure.

If the injector is not within 100 mL (3.4 oz) to 130 mL (4.4 oz), replace the DEF injector assembly. Refer to Disassembly and Assembly, DEF Injector and Mounting - Remove and Install for the correct procedure.

Ensure that the latest flash file is installed in the Engine ECM.

Use the electronic service tool to perform the "Aftertreatment Recovery Procedure".

Conduct an "Aftertreatment System Functional Test". This test is located within the electronic service tool, “Diagnostics" on the main menu, then click "Diagnostic Tests".

If test is successful and no codes are present, return the machine to service.

If test is unsuccessful, contact the Dealer Solutions Network (DSN).

Submit the following items to the email address below:

"TIB Check List"

"Product Status Reports"

DEF injector deposits photographs

CEM deposit photographs

DEF injector part number and serial number photographventers_phil

Table 1

TIB Check List

Step Number Completed (Yes / No) Results / Comments

Step 1. Download "Product Status Report" (PSR) from the engine ECM and send to the email address in the instructions.

Step 2. Record the CEM serial number.

Step 3. "DEF Pressure Is High" troubleshooting.

A. Check the DEF lines for a restriction.

B. Replace the pressure and backflow fittings.

C. Check for a restriction in the DEF pump.

D. Perform an "Aftertreatment System Functional Test".

Step 4. Download "Product Status Report" (PSR) from the engine ECM and send to the email address in the instructions.

Step 5. Aftertreatment SCR System Dosing Test.

A. DEF Injector deposit photograph taken. CEM deposit photograph taken.

Step 6. DEF Injector part number and serial number