Information injection-pump assembly

ZEXEL

106671-7571

1066717571

Rating:

Service parts 106671-7571 INJECTION-PUMP ASSEMBLY:

1.

_

3.

GOVERNOR

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

ME056357

12.

Open Pre:MPa(Kqf/cm2)

17.7{180}/21.6{220}

15.

NOZZLE SET

Include in #1:

106671-7571

as INJECTION-PUMP ASSEMBLY

Cross reference number

ZEXEL

106671-7571

1066717571

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131424-6920

Overflow valve opening pressure

kPa

191

157

225

Overflow valve opening pressure

kgf/cm2

1.95

1.6

2.3

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

4.8

4.75

4.85

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

-

Rack position

9.3

Pump speed

r/min

700

700

700

Each cylinder's injection qty

mm3/st.

144

140.5

147.5

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

F

Rack position

5+-0.5

Pump speed

r/min

500

500

500

Each cylinder's injection qty

mm3/st.

16.5

14

19

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(9.3)

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

144

143

145

Basic

*

Fixing the lever

*

Boost pressure

kPa

28

28

Boost pressure

mmHg

210

210

Injection quantity adjustment_04

Adjusting point

B

Rack position

9.65+-0.

5

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

161

159

163

Fixing the lever

*

Boost pressure

kPa

28

28

Boost pressure

mmHg

210

210

Injection quantity adjustment_05

Adjusting point

C

Rack position

5.5+-0.5

Pump speed

r/min

225

225

225

Each cylinder's injection qty

mm3/st.

16.5

14

19

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Remarks

(check)

(check)

Injection quantity adjustment_06

Adjusting point

D

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

130

110

150

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_07

Adjusting point

G

Rack position

9.8+-0.5

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

153

151

155

Fixing the lever

*

Boost pressure

kPa

28

28

Boost pressure

mmHg

210

210

Boost compensator adjustment

Pump speed

r/min

600

600

600

Rack position

8.1

Boost pressure

kPa

4

4

4

Boost pressure

mmHg

30

30

30

Boost compensator adjustment_02

Pump speed

r/min

600

600

600

Rack position

R1-0.7

Boost pressure

kPa

8

6.7

9.3

Boost pressure

mmHg

60

50

70

Boost compensator adjustment_03

Pump speed

r/min

600

600

600

Rack position

R1(9.3)

Boost pressure

kPa

14.7

14.7

14.7

Boost pressure

mmHg

110

110

110

Test data Ex:

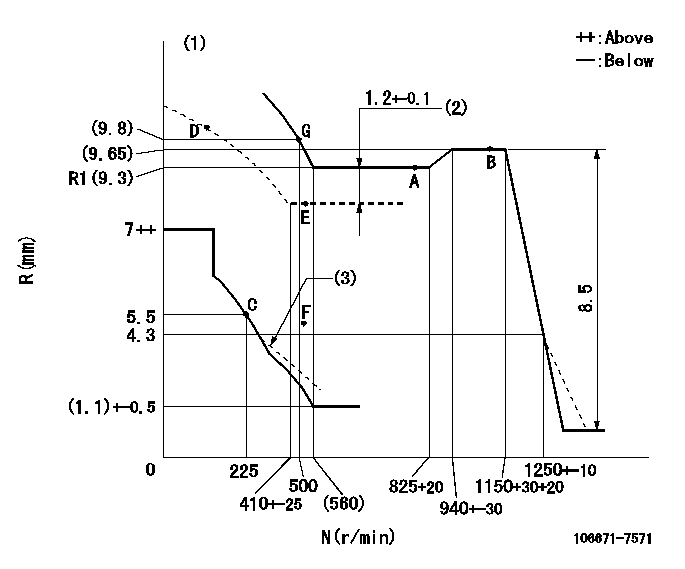

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Boost compensator cancel stroke: BSL

(2)Boost compensator stroke

(3)Damper spring setting: DL

----------

BSL=1.2mm DL=4.1-0.2mm

----------

----------

BSL=1.2mm DL=4.1-0.2mm

----------

Timer adjustment

(1)Adjusting range

(2)Step response time

(N): Speed of the pump

(L): Load

(theta) Advance angle

(Srd1) Step response time 1

(Srd2) Step response time 2

1. Adjusting conditions for the variable timer

(1)Adjust the clearance between the pickup and the protrusion to L.

----------

L=1-0.2mm N2=800r/min C2=(8.8)deg t1=2.5--sec. t2=2.5--sec.

----------

N1=750++r/min P1=0kPa(0kgf/cm2) P2=392kPa(4kgf/cm2) C1=8.8+-0.3deg R01=0/4load R02=4/4load

----------

L=1-0.2mm N2=800r/min C2=(8.8)deg t1=2.5--sec. t2=2.5--sec.

----------

N1=750++r/min P1=0kPa(0kgf/cm2) P2=392kPa(4kgf/cm2) C1=8.8+-0.3deg R01=0/4load R02=4/4load

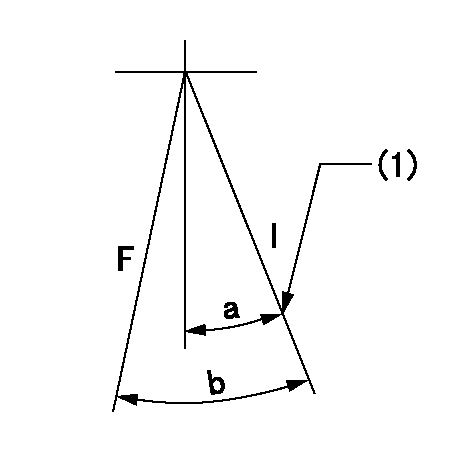

Speed control lever angle

F:Full speed

----------

----------

a=16.5deg+-5deg

----------

----------

a=16.5deg+-5deg

0000000901

F:Full load

I:Idle

(1)Stopper bolt setting

----------

----------

a=28deg+-5deg b=(30deg)+-3deg

----------

----------

a=28deg+-5deg b=(30deg)+-3deg

Stop lever angle

N:Engine manufacturer's normal use

S:Stop the pump.

(1)Rack position = aa

(2)Stopper bolt setting

(3)Rack position bb

(4)Free (at shipping)

----------

aa=4.1-0.5mm bb=13.3mm

----------

a=26deg+-5deg b=(38deg) c=0deg+7deg-5deg

----------

aa=4.1-0.5mm bb=13.3mm

----------

a=26deg+-5deg b=(38deg) c=0deg+7deg-5deg

0000001501 MICRO SWITCH

Adjustment of the micro-switch

Adjust the bolt to obtain the following lever position when the micro-switch is ON.

(1)Speed N1

(2)Rack position Ra

----------

N1=325+-5r/min Ra=5.2mm

----------

----------

N1=325+-5r/min Ra=5.2mm

----------

0000001601 RACK SENSOR

V1:Supply voltage

V2f:Full side output voltage

V2i:Idle side output voltage

(A) Black

(B) Yellow

(C) Red

(D) Trimmer

(E): Shaft

(F) Nut

(G) Load lever

1. Load sensor adjustment

(1)Connect as shown in the above diagram and apply supply voltage V1.

(2)Hold the load lever (G) against the full side.

(3)Turn the shaft so that the voltage between (A) and (B) is V2.

(4)Hold the load lever (G) against the idle side.

(5)Adjust (D) so that the voltage between (A) and (B) is V2i.

(6)Repeat the above adjustments.

(7)Tighten the nut (F) at the point satisfying the standards.

(8)Hold the load lever against the full side stopper and the idle side stopper.

(9)At this time, confirm that the full side output voltage is V2f and the idle side output voltage is V2i.

----------

V1=5+-0.02V V2f=0.15+0.03V V2i=2.35-0.03V

----------

----------

V1=5+-0.02V V2f=0.15+0.03V V2i=2.35-0.03V

----------

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(7deg)

----------

----------

a=(7deg)

Information:

Table 1

Part Number Part Description Qty

378-3187 Diesel Exhaust Fluid Filter Gp 1

423-3251 Connector 1

391-5262 Gasket 1

425-0385 Filter As 1

452-6055 Filter Base As 1

453-1604(1) Diesel Exhaust Fluid Filter Gp 1

453-1605(1) Diesel Exhaust Fluid Filter Gp 1

453-1606(1) Diesel Exhaust Fluid Filter Gp 1

(1) Use Table 2 to choose the correct part that corresponds to the DEF heater

Table 2

DEF Heater Part Number Required DEF Filter

434-3241 453-1604

434-3242 453-1605

434-3243 453-1606 The effective serial numbers for this change are related to the Pump Electronic Tank Unit (PETU) serial numbers and not the machine serial numbers. Table 3 contains the effective serial numbers for the PETU tank. Refer to illustration 1 and illustration 2 for examples of where to locate the PETU serial number.

Illustration 1 g06018843

Typical example

(1) The location of the PETU serial plate.

Illustration 2 g03418749

Typical example

Table 3

PETU Effective Serial Numbers

S/N:PET007086T-UP Refer to Special Instruction, M0066142, A New Diesel Exhaust Fluid Filter is Now Available for C7.1 Engines for installation instructions.