Information injection-pump assembly

BOSCH

9 400 616 937

9400616937

ZEXEL

106671-7431

1066717431

MITSUBISHI

ME056613

me056613

Rating:

Service parts 106671-7431 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

ME056329

12.

Open Pre:MPa(Kqf/cm2)

17.7{180}/21.6{220}

15.

NOZZLE SET

Include in #1:

106671-7431

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 400 616 937

9400616937

ZEXEL

106671-7431

1066717431

MITSUBISHI

ME056613

me056613

Zexel num

Bosch num

Firm num

Name

9 400 616 937

ME056613 MITSUBISHI

INJECTION-PUMP ASSEMBLY

6D22 K 14CA INJECTION PUMP ASSY PE6P,6PD PE

6D22 K 14CA INJECTION PUMP ASSY PE6P,6PD PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131424-4620

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

4.8

4.75

4.85

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

-

Rack position

8.1

Pump speed

r/min

700

700

700

Each cylinder's injection qty

mm3/st.

109

106.3

111.7

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

F

Rack position

5+-0.5

Pump speed

r/min

500

500

500

Each cylinder's injection qty

mm3/st.

16.5

14

19

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(8.1)

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

109

108

110

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

C

Rack position

5.7+-0.5

Pump speed

r/min

225

225

225

Each cylinder's injection qty

mm3/st.

16.5

14

19

Fixing the rack

*

Remarks

(check)

(check)

Injection quantity adjustment_05

Adjusting point

E

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

150

110

190

Fixing the lever

*

Remarks

After startup boost setting

After startup boost setting

Timer adjustment

Pump speed

r/min

950

Advance angle

deg.

0.5

Timer adjustment_02

Pump speed

r/min

1050

Advance angle

deg.

2.2

1.7

2.7

Timer adjustment_03

Pump speed

r/min

1150

Advance angle

deg.

5.5

5

6

Remarks

Finish

Finish

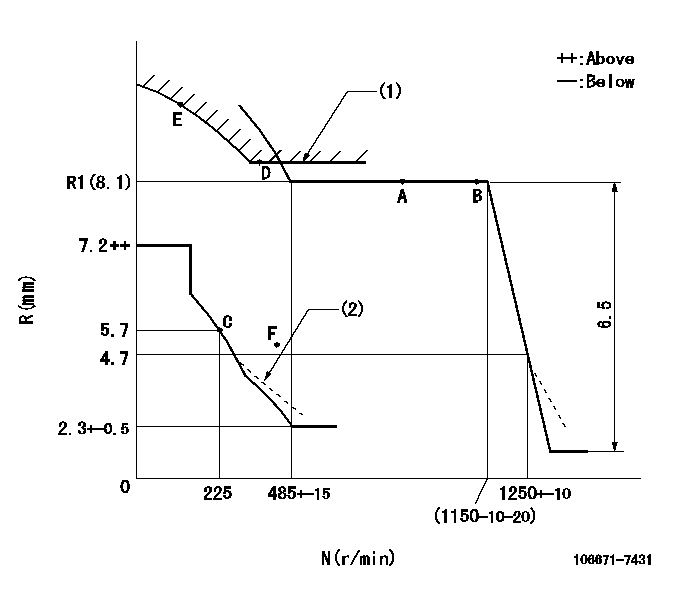

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Excess fuel setting for starting: SXL

(2)Damper spring setting: DL

----------

SXL=R1+1+0.8mm DL=4.5-0.2mm

----------

----------

SXL=R1+1+0.8mm DL=4.5-0.2mm

----------

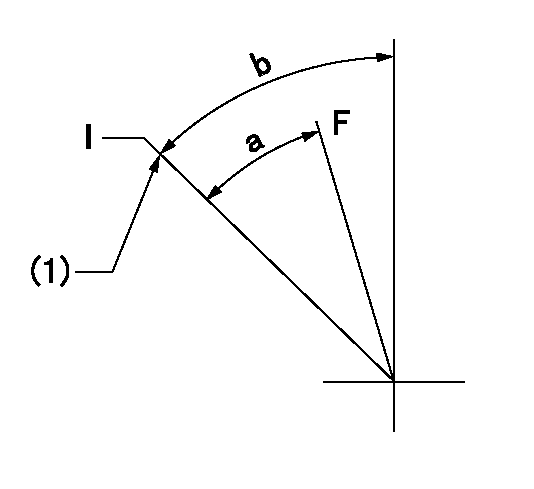

Speed control lever angle

F:Full speed

----------

----------

a=27deg+-5deg

----------

----------

a=27deg+-5deg

0000000901

F:Full load

I:Idle

(1)Stopper bolt setting

----------

----------

a=21.5deg+-3deg b=24deg+-5deg

----------

----------

a=21.5deg+-3deg b=24deg+-5deg

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Rack position = aa

(2)Rack position = bb, set the stopper bolt.

(3)Free (at shipping)

----------

aa=16.6mm bb=4.1-0.5mm

----------

a=35deg+-5deg b=61.5deg+7deg-5deg c=(6deg)

----------

aa=16.6mm bb=4.1-0.5mm

----------

a=35deg+-5deg b=61.5deg+7deg-5deg c=(6deg)

0000001501 LEVER

(1)Viewed from top of pump.

(2)Pump side

(3)Load control lever

(4)Adjusting bolt

(5)Nut

1. Idle increase link mechanism adjustment

(1)After completing pump and governor adjustment, fix the load control lever in the idle position.

(2)Adjust using the bolt (4) so that the idle-increase link mechanism's lever angle is a, then fix using the nut (5).

----------

----------

a=8.5deg+-3deg

----------

----------

a=8.5deg+-3deg

0000001601 MICRO SWITCH

Adjustment of the micro-switch

Adjust the bolt to obtain the following lever position when the micro-switch is ON.

(1)Speed N1

(2)Rack position Ra

----------

N1=325+-5r/min Ra=5.4mm

----------

----------

N1=325+-5r/min Ra=5.4mm

----------

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(7deg)

----------

----------

a=(7deg)

Information:

Do not use a commercial coolant/antifreeze that only meets the ASTM "D3306" specification. This type of coolant/antifreeze is made for light duty automotive applications.Use only the coolant/antifreeze that is recommended.

Note: Caterpillar recommends a 1:1 mixture of water and glycol. This mixture of water and glycol will provide optimum heavy-duty performance as a coolant/antifreeze.Note: Caterpillar DEAC DOES NOT require a treatment with an Supplemental Coolant Additive (SCA) at the initial fill. Commercial heavy-duty coolant/antifreeze that meets "ASTM D4985" or "ASTM D6210" specifications MAY require a treatment with a supplemental coolant additive at the initial fill. Read the label or the instructions that are provided by the OEM of the product.Note: These coolants WILL require a treatment with a supplemental coolant additive on a maintenance basis. Regardless of the ambient temperature, the supplemental coolant additive should be maintained between three to six percent. The Caterpillar 4C-9297 Test Strip can be used to help maintain the appropriate concentration of Caterpillar SCA.

All Caterpillar diesel engines equipped with air-to-air aftercooling (ATAAC) require a minimum of 30 percent glycol to prevent water pump cavitation.

Glycol

For optimum performance, Caterpillar recommends a 1:1 mixture of a water/glycol solution.Note: Use a mixture that will provide protection against the lowest ambient temperature.Note: 100 percent pure glycol will freeze at a temperature of −23 °C (−9 °F).

Table 1

Ethylene Glycol

Concentration Freeze Protection Boil Protection

50 Percent −36 °C (−33 °F) 106 °C (223 °F)

60 Percent −52 °C (−62 °F) 111 °C (232 °F) Check the coolant for the concentration of glycol frequently in cold weather with a refractometer type coolant tester in order to ensure adequate freeze protection.To check the concentration of glycol, use the 1U-7298 Coolant/Battery Tester (DEGREES CELSIUS) or use the 1U-7297 Coolant/Battery Tester (DEGREES FAHRENHEIT). The testers give readings that are immediate and accurate. The testers can be used with ethylene or propylene glycol.Water

Distilled water or deionized water is recommended for use in engine cooling systems. DO NOT use the following types of water in cooling systems: hard water, softened water that has been conditioned with salt, and sea water. Damage to the cooling system may result.

Note: If distilled water or deionized water is not available, use water with the properties that are listed in table 2.

Table 2

Caterpillar Minimum Acceptable Water Requirements

Property Maximum ASTM Specification

Chloride (Cl) 40 mg/L (2.4 grains per US gal) "D512"

"D4327"

Sulfate (SO4) 100 mg/L (5.9 grains per US gal) "D516"

Total Hardness 170 mg/L (10 grains per US gal) "D1126"

Total Solids 340 mg/L (20 grains per US gal) "D1888"

Acidity pH of 5.5 to 9.0 "D1293"