Information injection-pump assembly

BOSCH

9 400 616 936

9400616936

ZEXEL

106671-7421

1066717421

MITSUBISHI

ME056612

me056612

Rating:

Service parts 106671-7421 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

ME056329

12.

Open Pre:MPa(Kqf/cm2)

17.7(180)/21.6(220)

15.

NOZZLE SET

Include in #1:

106671-7421

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 400 616 936

9400616936

ZEXEL

106671-7421

1066717421

MITSUBISHI

ME056612

me056612

Zexel num

Bosch num

Firm num

Name

106671-7421

9 400 616 936

ME056612 MITSUBISHI

INJECTION-PUMP ASSEMBLY

6D22 * K

6D22 * K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131424-4620

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

4.8

4.75

4.85

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

-

Rack position

8.1

Pump speed

r/min

700

700

700

Each cylinder's injection qty

mm3/st.

109

106.3

111.7

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

F

Rack position

5+-0.5

Pump speed

r/min

500

500

500

Each cylinder's injection qty

mm3/st.

16.5

14

19

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(8.1)

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

109

108

110

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

C

Rack position

5.7+-0.5

Pump speed

r/min

225

225

225

Each cylinder's injection qty

mm3/st.

16.5

14

19

Fixing the rack

*

Remarks

(check)

(check)

Injection quantity adjustment_05

Adjusting point

E

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

150

110

190

Fixing the lever

*

Remarks

After startup boost setting

After startup boost setting

Timer adjustment

Pump speed

r/min

950

Advance angle

deg.

0.5

Timer adjustment_02

Pump speed

r/min

1050

Advance angle

deg.

2.2

1.7

2.7

Timer adjustment_03

Pump speed

r/min

1150

Advance angle

deg.

5.5

5

6

Remarks

Finish

Finish

Test data Ex:

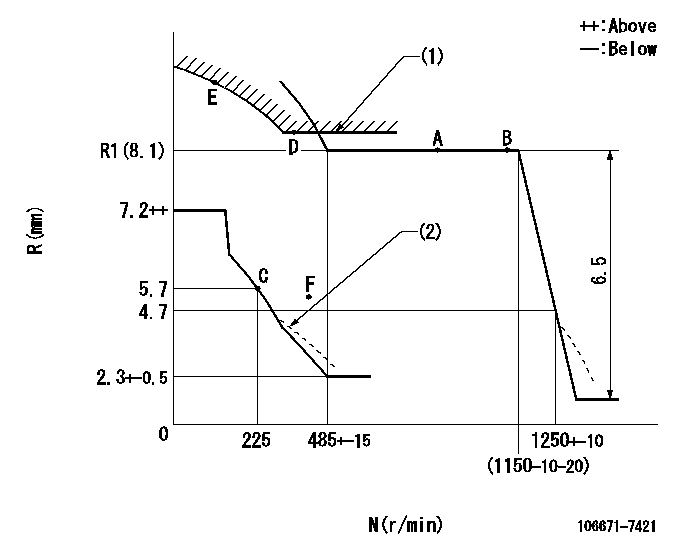

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Excess fuel setting for starting: SXL

(2)Damper spring setting: DL

----------

SXL=R1+1+0.8mm DL=4.5-0.2mm

----------

----------

SXL=R1+1+0.8mm DL=4.5-0.2mm

----------

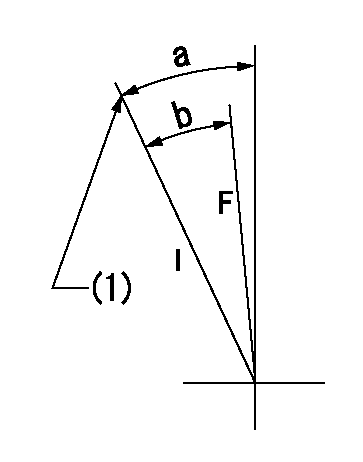

Speed control lever angle

F:Full speed

----------

----------

a=27deg+-5deg

----------

----------

a=27deg+-5deg

0000000901

F:Full load

I:Idle

(1)Stopper bolt setting

----------

----------

a=24deg+-5deg b=21.5deg+-3deg

----------

----------

a=24deg+-5deg b=21.5deg+-3deg

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Rack position = aa

(2)Set the stopper bolt at rack position = bb

(3)Free (at shipping)

----------

aa=16.6mm bb=4.1-0.5mm

----------

a=35deg+-5deg b=61.5deg+7deg-5deg c=(6deg)

----------

aa=16.6mm bb=4.1-0.5mm

----------

a=35deg+-5deg b=61.5deg+7deg-5deg c=(6deg)

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(7deg)

----------

----------

a=(7deg)

Information:

Preferred Fuel Grades

The two main types of diesel fuel that are available for your truck engine are typically low sulfur No. 1 diesel fuel and low sulfur No. 2 diesel fuel. Although No. 2 diesel fuels are the most commonly used fuel, No. 1 diesel fuels or a blend of No. 1 diesel fuel and No. 2 diesel fuel is best suited for cold weather operation.There are three major differences between No. 1 diesel fuel and No. 2 diesel fuel.

No. 1 diesel fuel has a lower cloud point. The fuel cloud point is the temperature when a haze appears in the fuel. When the temperature falls below the melting point of the paraffins a haze results. Paraffins are a wax that naturally occurs in petroleum products. The wax can alter the fuel characteristics in cold weather. Solid wax can fill the fuel filters. The solidified wax will stop the flow of fuel. The cloud point must not exceed the lowest expected ambient temperature or other precautions must be taken. Installing a fuel heater is the most practical way to address problems with the cloud point.

No. 1 diesel fuel has a lower pour point. The pour point of the fuel is the temperature that is 3 °C (5 °F) above the temperature that is required for fuel to flow. Fuel stops flowing below the pour point. A fuel's pour point should be at least 6°C (10°F) below the lowest ambient temperature that is required for engine start-up and for engine operation.

No. 1 diesel fuel has a lower rating for kJ or Btu per unit volume of fuel than the average No. 2 diesel fuel.

Table 1

Fuel Recommendations for Ambient Temperatures

Fuel Type Temperature Range(1)

No. 2 Above 0 °C (32 °F)

No. 1 −30 °C (−22 °F) to 0 °C (32 °F)

(1) Contact your Caterpillar dealer for information regarding the acceptable fuels and/or the acceptable blends, if there is potential for colder operating temperatures.No. 2 diesel fuel may be blended with No. 1 diesel fuel or blended with kerosene in the following proportions in order to achieve the capability to flow at lower temperatures.

Table 2

Modification of No. 2 Fuel

Ambient Temperature No. 2 Diesel Fuel (%)(1) No. 1 Diesel Fuel(1)

Above −10 °C (14 °F) 90 10

−10 °C (14 °F) to −20 °C (−4 °F) 70 30

Temperatures below −20 °C (−4 °F) 50 50

(1) Never blend the fuel with gasoline under any circumstances.No. 1 diesel fuel does not have the same energy per unit volume as No. 2 diesel fuel. No. 1 diesel fuel has less energy per unit volume. A reduction in power and fuel efficiency may be noticed with No. 1 diesel fuel or a blend of No. 1 diesel fuel and No. 2 diesel fuel but other operating effects should not be experienced.Check the type of fuel or the fuel blend that is being used before troubleshooting for poor performance during the winter. Be aware of these values when you purchase diesel fuel. Anticipate the average outside temperature for the area for operation

The two main types of diesel fuel that are available for your truck engine are typically low sulfur No. 1 diesel fuel and low sulfur No. 2 diesel fuel. Although No. 2 diesel fuels are the most commonly used fuel, No. 1 diesel fuels or a blend of No. 1 diesel fuel and No. 2 diesel fuel is best suited for cold weather operation.There are three major differences between No. 1 diesel fuel and No. 2 diesel fuel.

No. 1 diesel fuel has a lower cloud point. The fuel cloud point is the temperature when a haze appears in the fuel. When the temperature falls below the melting point of the paraffins a haze results. Paraffins are a wax that naturally occurs in petroleum products. The wax can alter the fuel characteristics in cold weather. Solid wax can fill the fuel filters. The solidified wax will stop the flow of fuel. The cloud point must not exceed the lowest expected ambient temperature or other precautions must be taken. Installing a fuel heater is the most practical way to address problems with the cloud point.

No. 1 diesel fuel has a lower pour point. The pour point of the fuel is the temperature that is 3 °C (5 °F) above the temperature that is required for fuel to flow. Fuel stops flowing below the pour point. A fuel's pour point should be at least 6°C (10°F) below the lowest ambient temperature that is required for engine start-up and for engine operation.

No. 1 diesel fuel has a lower rating for kJ or Btu per unit volume of fuel than the average No. 2 diesel fuel.

Table 1

Fuel Recommendations for Ambient Temperatures

Fuel Type Temperature Range(1)

No. 2 Above 0 °C (32 °F)

No. 1 −30 °C (−22 °F) to 0 °C (32 °F)

(1) Contact your Caterpillar dealer for information regarding the acceptable fuels and/or the acceptable blends, if there is potential for colder operating temperatures.No. 2 diesel fuel may be blended with No. 1 diesel fuel or blended with kerosene in the following proportions in order to achieve the capability to flow at lower temperatures.

Table 2

Modification of No. 2 Fuel

Ambient Temperature No. 2 Diesel Fuel (%)(1) No. 1 Diesel Fuel(1)

Above −10 °C (14 °F) 90 10

−10 °C (14 °F) to −20 °C (−4 °F) 70 30

Temperatures below −20 °C (−4 °F) 50 50

(1) Never blend the fuel with gasoline under any circumstances.No. 1 diesel fuel does not have the same energy per unit volume as No. 2 diesel fuel. No. 1 diesel fuel has less energy per unit volume. A reduction in power and fuel efficiency may be noticed with No. 1 diesel fuel or a blend of No. 1 diesel fuel and No. 2 diesel fuel but other operating effects should not be experienced.Check the type of fuel or the fuel blend that is being used before troubleshooting for poor performance during the winter. Be aware of these values when you purchase diesel fuel. Anticipate the average outside temperature for the area for operation

Have questions with 106671-7421?

Group cross 106671-7421 ZEXEL

Mitsubishi

106671-7421

9 400 616 936

ME056612

INJECTION-PUMP ASSEMBLY

6D22

6D22