Information injection-pump assembly

ZEXEL

106671-7330

1066717330

MITSUBISHI-HEAV

3256510160

3256510160

Rating:

Cross reference number

ZEXEL

106671-7330

1066717330

MITSUBISHI-HEAV

3256510160

3256510160

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8130

Bosch type code

EFEP215A

Nozzle

105780-0050

Bosch type code

DN6TD119NP1T

Nozzle holder

105780-2090

Bosch type code

EFEP215

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131424-3720

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

2.7

2.65

2.75

Rack position

Point A R=A

Point A R=A

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

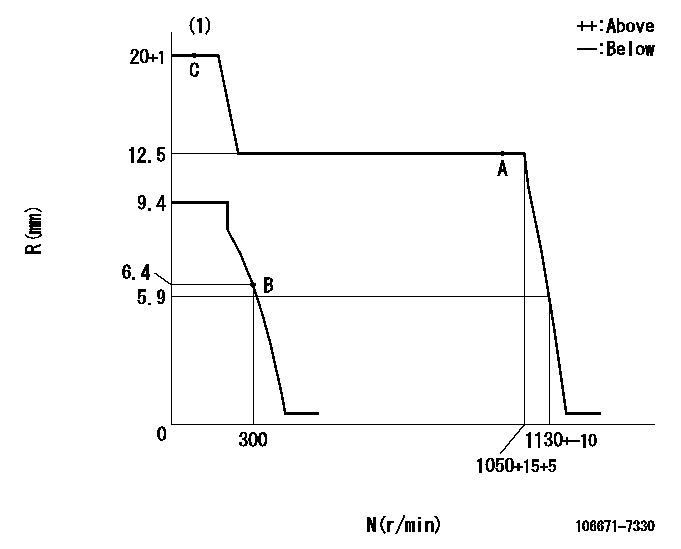

Injection quantity adjustment

Adjusting point

A

Rack position

12.5

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

373

364

382

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

6.4+-0.5

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

67.1

64.1

70.1

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Timer adjustment

Pump speed

r/min

400

Advance angle

deg.

0.5

Timer adjustment_02

Pump speed

r/min

700

Advance angle

deg.

1.2

0.7

1.7

Timer adjustment_03

Pump speed

r/min

1050

Advance angle

deg.

3.5

3

4

Timer adjustment_04

Pump speed

r/min

-

Advance angle

deg.

4

4

4

Remarks

Measure the actual speed, stop

Measure the actual speed, stop

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

----------

K=4

----------

----------

K=4

----------

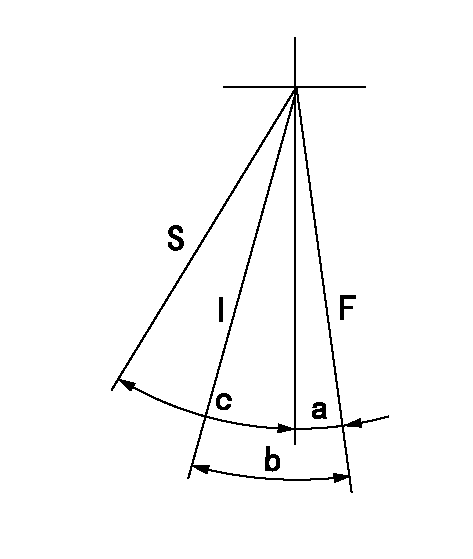

Speed control lever angle

F:Full speed

I:Idle

S:Stop

----------

----------

a=(1deg)+-5deg b=(25deg)+-5deg c=32deg+-3deg

----------

----------

a=(1deg)+-5deg b=(25deg)+-5deg c=32deg+-3deg

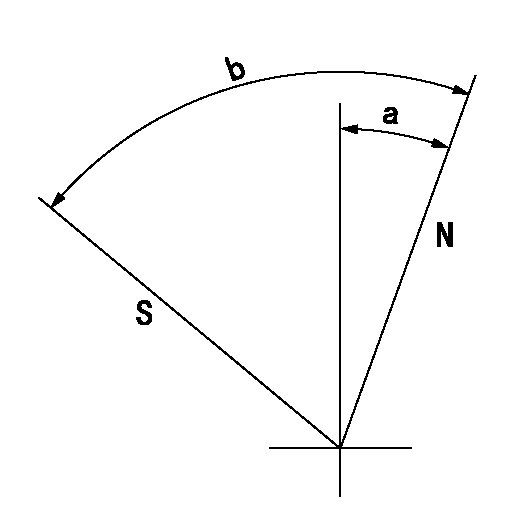

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=20deg+-5deg b=72deg+-5deg

----------

----------

a=20deg+-5deg b=72deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(20deg)

----------

----------

a=(20deg)

Information:

Disconnect all electrical power from the monitor before removing components. Failure to disconnect the power could result in severe electrical shock or damage to the monitor. An electrical shock can cause severe personal injury or death.

Choose the appropriate drive for your monitor from the table below. The 203-7811 Engine Monitoring Control Group uses Wonderware as the "Graphic Display Application". The 203-7810 Engine Monitoring Control Group uses RSView as the "Graphic Display Application".

Table 1

Drive "Graphic Display Application"

203-7816 Storage Drive RSView

204-8792 Storage Drive Wonderware In order to install the drive, perform the procedure that follows:

Connect the ribbon cable connector and power cables to the hard drive and the floppy disk drive.Note: Make sure that the ribbon cable is correctly installed. The connector must be positioned so that the red wire of the cable is closest to the back of the unit. If you are using the new cables, also connect the other end of the cables to the Central Processing Unit (CPU) card.

Illustration 1 g00858453

(1) Drive Bay Mounting Studs

Position the drive bay into the chassis so that the studs (1) on the chassis fit into the grommets on the drive bay.Note: Be careful not to push the vibration dampers (grommets) on the drive bay out of the sheet metal.

Install the back cover.

Apply power and verify the operation of the drive. Refer to any additional instructions that are provided with the drive.