Information injection-pump assembly

ZEXEL

106671-7170

1066717170

MITSUBISHI-HEAV

3256520060

3256520060

Rating:

Service parts 106671-7170 INJECTION-PUMP ASSEMBLY:

1.

_

2.

FUEL INJECTION PUMP

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

29.4{300}

15.

NOZZLE SET

Include in #1:

106671-7170

as INJECTION-PUMP ASSEMBLY

Cross reference number

ZEXEL

106671-7170

1066717170

MITSUBISHI-HEAV

3256520060

3256520060

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8130

Bosch type code

EFEP215A

Nozzle

105780-0050

Bosch type code

DN6TD119NP1T

Nozzle holder

105780-2090

Bosch type code

EFEP215

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131424-3720

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

2.7

2.65

2.75

Rack position

Point A R=A

Point A R=A

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

12.5

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

373

364

382

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

6.4+-0.5

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

67.1

64.1

70.1

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Timer adjustment

Pump speed

r/min

400

Advance angle

deg.

0.5

Timer adjustment_02

Pump speed

r/min

700

Advance angle

deg.

1.2

0.7

1.7

Timer adjustment_03

Pump speed

r/min

1050

Advance angle

deg.

3.5

3

4

Timer adjustment_04

Pump speed

r/min

-

Advance angle

deg.

4

4

4

Remarks

Measure the actual speed, stop

Measure the actual speed, stop

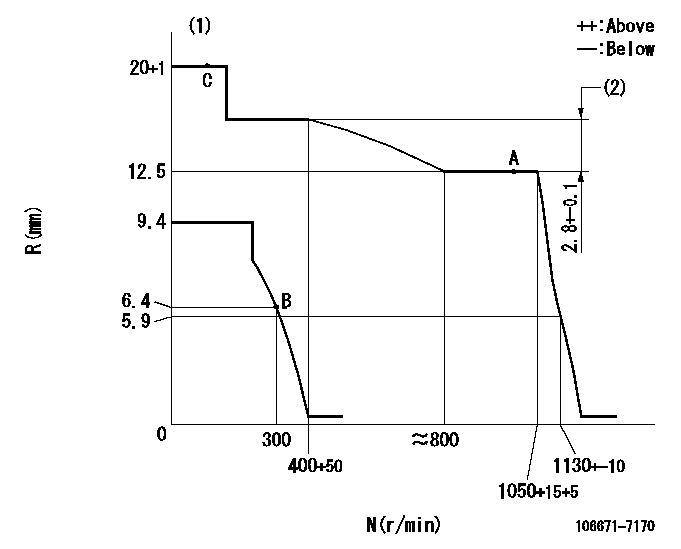

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Rack difference between N = N1 and N = N2

----------

K=8 N1=1000r/min N2=350r/min

----------

----------

K=8 N1=1000r/min N2=350r/min

----------

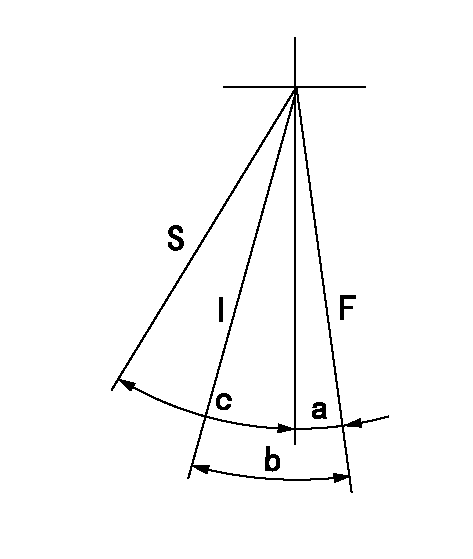

Speed control lever angle

F:Full speed

I:Idle

S:Stop

----------

----------

a=7deg+-5deg b=29deg+-5deg c=32deg+-3deg

----------

----------

a=7deg+-5deg b=29deg+-5deg c=32deg+-3deg

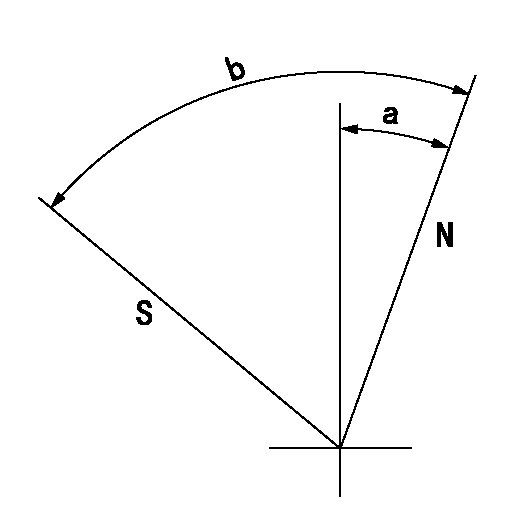

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=20deg+-5deg b=72deg+-5deg

----------

----------

a=20deg+-5deg b=72deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(20deg)

----------

----------

a=(20deg)

Information:

Table 1

Additional Troubleshooting

Problem Possible Explanation Required Action

Direct Connections

PC unable to connect to CCM PC is configured improperly, or a cable error is present. Determine if the proper serial port on the PC has been selected. Make sure the correct RS-232C cable is being used. Null modem cable is required. Match the PC configuration with the CCM configuration.

Modem Connections

PC unable to connect to CCM PC configured improperly, modem not set up properly, or cable error is present. PC modem and CCM modem are not compatible.

Password was not entered within 60 seconds Determine if proper serial port on the PC is selected. Make sure that the Communication Specifications are being met and consult the modem manual. Make sure the correct RS-232C cable is being used. No null modem is required. Match the CCM, PC, and modem configurations.

Modem does not answer Improper modem configuration. Verify that the modem is configured per the instructions given in the Communication Initialization section in this manual.

Modem disconnects during remote start. System battery voltage is low. Make sure that the (+/-) Battery Power Specifications are being met. It may be necessary to disconnect the phone line on the local modem temporarily to force it to hang up.

Direct or Modem Connections

PC can connect to only one electronic controller in a multiple unit installation. Electronic controller MID has not been programmed.

Electronic controllers are not connected on the correct data link. Refer to Programming the Engine Number section and Data Link Guidelines section in this manual.

PC will not connect to 3500B marine propulsion engine through the CCM PC software. CCM has been installed on the wrong data link. CCM PC software version 1.2 and earlier will not communicate with the CCM if the CCM is connected via the primary Data Link on 3500B Marine Engines built after 4/97. The CCM should be connected to the Secondary CAT Data Link on these engines when used as a communications interface. Refer to the Data Link Guidelines section in this manual.