Information injection-pump assembly

BOSCH

9 400 616 928

9400616928

ZEXEL

106671-7121

1066717121

MITSUBISHI

ME056495

me056495

Rating:

Service parts 106671-7121 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

ME056329

12.

Open Pre:MPa(Kqf/cm2)

17.7(180)/21.6(220)

15.

NOZZLE SET

Include in #1:

106671-7121

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 400 616 928

9400616928

ZEXEL

106671-7121

1066717121

MITSUBISHI

ME056495

me056495

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131424-4620

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

4.8

4.75

4.85

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

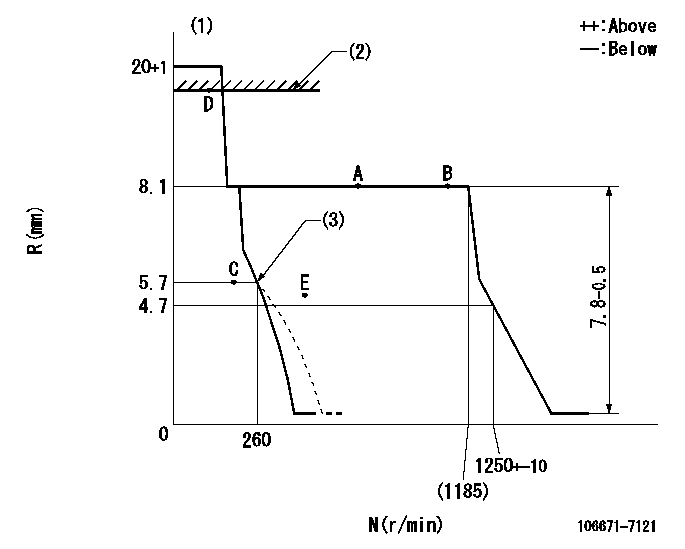

Injection quantity adjustment

Adjusting point

-

Rack position

8.1

Pump speed

r/min

700

700

700

Each cylinder's injection qty

mm3/st.

109

106.3

111.7

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

E

Rack position

5+-0.5

Pump speed

r/min

500

500

500

Each cylinder's injection qty

mm3/st.

16.5

14

19

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

5.7+-0.5

Pump speed

r/min

225

225

225

Each cylinder's injection qty

mm3/st.

16.5

14

19

Fixing the rack

*

Remarks

(check)

(check)

Injection quantity adjustment_04

Adjusting point

A

Rack position

R1(8.1)

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

109

108

110

Basic

*

Fixing the lever

*

Injection quantity adjustment_05

Adjusting point

D

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

150

130

170

Fixing the lever

*

Rack limit

*

Timer adjustment

Pump speed

r/min

950

Advance angle

deg.

0.5

Timer adjustment_02

Pump speed

r/min

1050

Advance angle

deg.

2.2

1.7

2.7

Timer adjustment_03

Pump speed

r/min

1150

Advance angle

deg.

5.5

5

6

Remarks

Finish

Finish

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Notch fixed: K

(2)RACK LIMIT

(3)Idle sub spring setting: L1.

----------

K=9 L1=5.7-0.2mm

----------

----------

K=9 L1=5.7-0.2mm

----------

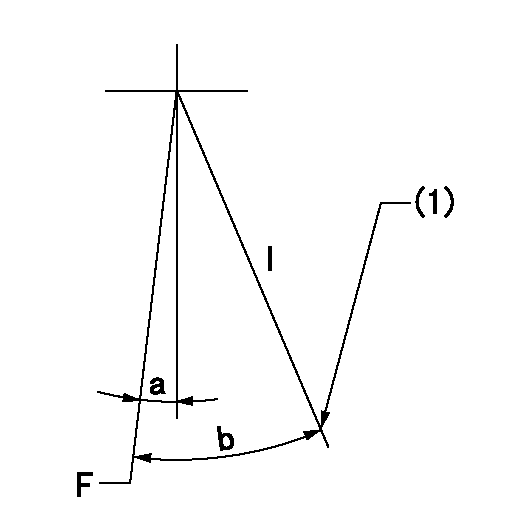

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=6deg+-5deg b=18deg+-5deg

----------

----------

a=6deg+-5deg b=18deg+-5deg

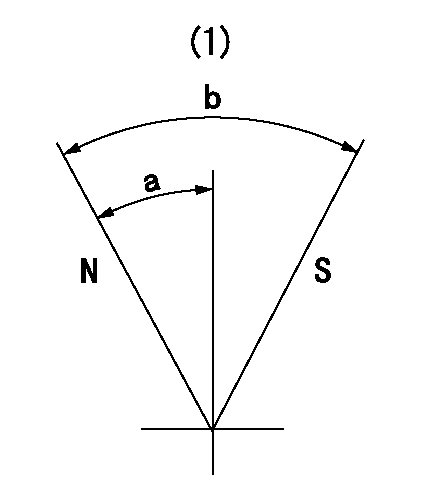

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Upper lever angle

----------

----------

a=19.5deg+-5deg b=46deg+-5deg

----------

----------

a=19.5deg+-5deg b=46deg+-5deg

0000001501 MICRO SWITCH

Adjustment of the micro-switch

Adjust the bolt to obtain the following lever position when the micro-switch is ON.

(1)Speed N1

(2)Rack position Ra

----------

N1=325+-5r/min Ra=5.4mm

----------

----------

N1=325+-5r/min Ra=5.4mm

----------

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(7deg)

----------

----------

a=(7deg)

Information:

Table 9

Byte(s) Byte Contents Detailed Description

1 $50 Indicates M5X protocol

2 $01 CCM is the sending module

3 $25 IID 25

4 $07 Number of bytes

5 $58 GSC number 1

6, 7 $00 $82 PID $0082 GSC Fault Log Codes, Status, And Number of occurrences

8, 9 $00 $BE CID 190 (engine speed sensor fault)

10 $C3 Count included, inactive fault, logged fault, standard FMI (3)

11 $04 Occurrence count of 4

12 $24 Checksum

IID 00 is used to request additional information on a fault 500000070058008300BEC34DIID 00 - Special parameter Command

Table 10

Byte(s) Byte Contents Detailed Description

1 $50 Indicates M5X protocol

2 $01 CCM is the sending module

3 $00 IID 00

4 $07 Number of bytes

5 $00 Reply in ASCII format

6 $58 GSC number 1

7, 8 $00 $83 PID $0083 GSC Fault Log Request For Additional Data

9, 10, 11 $00 $BE $C3 More information requested on CID 190 FMI 3

12 $4D Checksum

IID 25 will contain the reply as PID $0084 5001250B58008400BEC303000C001102IID 25 - Single Parameter Read Response

Table 11

Byte(s) Byte Contents Detailed Description

1 $50 Indicates M5X protocol

2 $01 CCM is the sending module

3 $25 IID 25

4 $0B Number of bytes

5 $58 GSC number 1

6, 7 $00 $84 PID $0084 GSC Fault Log Response For Additional Data

8, 9 $00 $BE CID 190

10 $C3 More information on FMI 3

11 $03 Three occurrences of this fault

12, 13 $00 $0C First occurrence at 12 hours

14, 15 $00 $11 Last occurrence at 17 hours

16 $02 Checksum Monitoring Generator Phase

The following example shows how to select which generator phase the GSC monitors.

Use IID 34 to write the parameters of PID $F0B0: 500034050048F0B0007FIID 34 - Single Parameter Write Request

Table 12

Byte(s) Byte Contents Detailed Description

1 $50 Indicates M5X protocol

2 $00 User's PC is the sending module

3 $34 IID 34

4 $05 Number of bytes

5 $00 Reply in ASCII format

6 $58 GSC number 1

7, 8 $F0 $B0 PID $F0B0 Generator Phase Select

9 $00 Phase A-B Voltage, Phase A Current

10 $7F Checksum

IID 35 is the response from the CCM: 5001350458F0B0007EIID 35 - Single Parameter Write Response

Table