Information injection-pump assembly

BOSCH

9 400 616 924

9400616924

ZEXEL

106671-7030

1066717030

MITSUBISHI

ME056462

me056462

Rating:

Service parts 106671-7030 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

ME056329

12.

Open Pre:MPa(Kqf/cm2)

17.7{180}/21.6{220}

15.

NOZZLE SET

Include in #1:

106671-7030

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 400 616 924

9400616924

ZEXEL

106671-7030

1066717030

MITSUBISHI

ME056462

me056462

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131424-4620

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

4.8

4.75

4.85

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

-

Rack position

7.9

Pump speed

r/min

700

700

700

Each cylinder's injection qty

mm3/st.

104

101.4

106.6

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

F

Rack position

5+-0.5

Pump speed

r/min

500

500

500

Each cylinder's injection qty

mm3/st.

16.5

14

19

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(7.9)

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

104

103

105

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1(7.9)

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

118

114

122

Difference in delivery

mm3/st.

8

8

8

Fixing the lever

*

Injection quantity adjustment_05

Adjusting point

C

Rack position

5.7+-0.5

Pump speed

r/min

225

225

225

Each cylinder's injection qty

mm3/st.

16.5

14

19

Fixing the rack

*

Remarks

(check)

(check)

Injection quantity adjustment_06

Adjusting point

E

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

150

130

170

Fixing the lever

*

Timer adjustment

Pump speed

r/min

950

Advance angle

deg.

0.5

Timer adjustment_02

Pump speed

r/min

1050

Advance angle

deg.

2.2

1.7

2.7

Timer adjustment_03

Pump speed

r/min

1150

Advance angle

deg.

5.5

5

6

Remarks

Finish

Finish

Test data Ex:

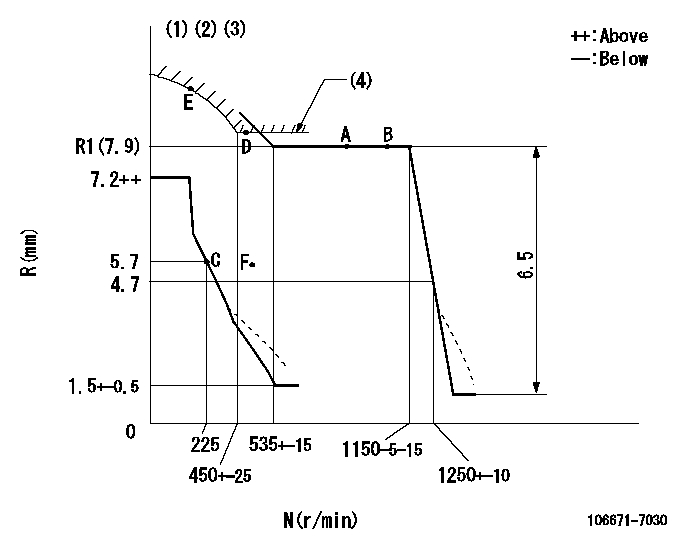

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Lever ratio: RT

(2)Target shim dimension: TH

(3)Damper spring setting: DL

(4)Excess fuel setting for starting: SXL

----------

RT=1 TH=2.6mm DL=4.5-0.2mm SXL=R1+0.2mm

----------

----------

RT=1 TH=2.6mm DL=4.5-0.2mm SXL=R1+0.2mm

----------

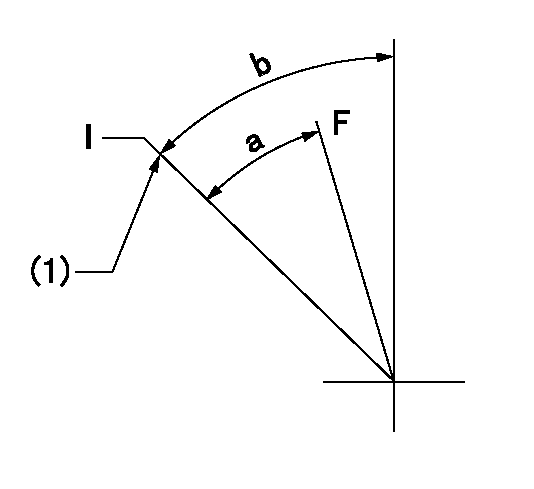

Speed control lever angle

F:Full speed

----------

----------

a=27deg+-5deg

----------

----------

a=27deg+-5deg

0000000901

F:Full load

I:Idle

(1)Stopper bolt setting

----------

----------

a=23deg+-3deg b=24deg+-5deg

----------

----------

a=23deg+-3deg b=24deg+-5deg

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Rack position = aa

(2)Set stopper bolt so that rack position = bb.

(3)Free (at shipping)

----------

aa=16.6mm bb=4.1-0.5mm

----------

a=35deg+-5deg b=61.5deg+7deg-5deg c=(6deg)

----------

aa=16.6mm bb=4.1-0.5mm

----------

a=35deg+-5deg b=61.5deg+7deg-5deg c=(6deg)

0000001501 MICRO SWITCH

Adjustment of the micro-switch

Adjust the bolt to obtain the following lever position when the micro-switch is ON.

(1)Speed N1

(2)Rack position Ra

----------

N1=325+-5r/min Ra=5.4mm

----------

----------

N1=325+-5r/min Ra=5.4mm

----------

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(7deg)

----------

----------

a=(7deg)

Information:

Version C of the ADEM II controller (ECM) has a primary data link for use with the CCM. This data link is called the CAT Data Link. The Module Identifier (MID) of this controller is a fixed value. Each controller on the CAT Data Link must have a unique MID. The CCM can only be connected to one Version C ECM on the CAT Data Link.

Version D of the ADEM II controller (ECM) also has a primary data link for use with the CCM. The value of the MID for the primary data link is fixed. Version D also has a secondary data link for use with the CCM. The Secondary CAT Data Link has a programmable MID. A maximum of eight different values is available for generator set applications. A maximum of three different values is available for marine applications.

EMCP II (basic model) has a primary data link for use with the CCM. This data link is called the CAT Data Link. The CAT Data Link has a programmable MID. A maximum of eight different values may be used for the MID.

EMCP II+ has the same primary data link as EMCP II (CAT Data Link) with a programmable value for the MID. The EMCP II+ also has a secondary data link for use with the CCM. The CCM Data Link has a programmable value for the MID. The CAT Data Link and the CCM Data Link have eight MID values.

The Secondary CAT Data Link and the CCM Data Link can be treated in the same manner on the 3500B Version D and the EMCP II+ applications.

There is a maximum of one CCM per data link.

There is a maximum of one CCM per engine.The previous descriptions govern the connections between the devices and the CCM. When an ADEM II controller and an EMCP II or EMCP II+ controller are connected, the CAT Data Link is always used for the connections. All subsequent connections to the CCM (ADEM II Version D or EMCP II+) are made by using the secondary data link. The following examples will illustrate some valid CCM connections with multiple electronic controllers. These examples are only a representation of most possible valid connections or combinations.

Illustration 1 g00649118

MUI Generator sets with EMCP II (Basic Model)

Illustration 2 g00649133

MUI Generator sets with EMCP II+

Illustration 3 g00649182

3500B EUI Generator set (Version C ECM)

Illustration 4 g00649184

3500 B EUI Generator sets (Version D ECM)

Illustration 5 g00649192

3500B EUI Generator sets (Version C and D ECM's)For the application that is shown in Illustration 5, only one Version C ECM is allowed.

Illustration 6 g00649200

3500B EUI Generator set (Version C ECM) with EMCP II (Basic Model)

Illustration 7 g00649317

EMCP II Basic and 3500B EUI Generator set (Version D ECM)One CCM is required for each engine with Version D ECM.

Illustration 8 g00649214

3500B EUI Generator sets (Version C ECM) with EMCP II+

Illustration 9 g00649236

3500B EUI Generator sets (Version D ECM) with EMCP II+

Illustration 10 g00649243

3500B EUI Generator sets (Version D ECM) with EMCP II+A maximum of four generator sets can be connected in the application that is shown in