Information injection-pump assembly

BOSCH

9 400 612 464

9400612464

ZEXEL

106671-6590

1066716590

ISUZU

1156034300

1156034300

Rating:

Service parts 106671-6590 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

1-15300-343-0

12.

Open Pre:MPa(Kqf/cm2)

22.1{225}

15.

NOZZLE SET

Include in #1:

106671-6590

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 400 612 464

9400612464

ZEXEL

106671-6590

1066716590

ISUZU

1156034300

1156034300

Zexel num

Bosch num

Firm num

Name

9 400 612 464

1156034300 ISUZU

INJECTION-PUMP ASSEMBLY

6HE1-TMC K 14CA INJECTION PUMP ASSY PE6P,6PD PE

6HE1-TMC K 14CA INJECTION PUMP ASSY PE6P,6PD PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

134424-3920

Overflow valve opening pressure

kPa

127

127

127

Overflow valve opening pressure

kgf/cm2

1.3

1.3

1.3

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

4

3.97

4.03

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.75 60.25

Cal 1-5 deg. 60 59.75 60.25

Difference between angles 2

Cal 1-3 deg. 120 119.75 120.25

Cal 1-3 deg. 120 119.75 120.25

Difference between angles 3

Cal 1-6 deg. 180 179.75 180.25

Cal 1-6 deg. 180 179.75 180.25

Difference between angles 4

Cyl.1-2 deg. 240 239.75 240.25

Cyl.1-2 deg. 240 239.75 240.25

Difference between angles 5

Cal 1-4 deg. 300 299.75 300.25

Cal 1-4 deg. 300 299.75 300.25

Injection quantity adjustment

Adjusting point

A

Rack position

11.5

Pump speed

r/min

1450

1450

1450

Average injection quantity

mm3/st.

127.5

125.5

129.5

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the lever

*

Boost pressure

kPa

180

180

Boost pressure

mmHg

1350

1350

Injection quantity adjustment_02

Adjusting point

C

Rack position

7.2+-0.5

Pump speed

r/min

275

275

275

Average injection quantity

mm3/st.

19

15.8

22.2

Max. variation between cylinders

%

0

-13

13

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Boost compensator adjustment

Pump speed

r/min

600

600

600

Rack position

7.7

Boost pressure

kPa

56

53.3

58.7

Boost pressure

mmHg

420

400

440

Boost compensator adjustment_02

Pump speed

r/min

600

600

600

Rack position

9.85

Boost pressure

kPa

167

160.3

173.7

Boost pressure

mmHg

1250

1200

1300

Timer adjustment

Pump speed

r/min

1400++

Advance angle

deg.

0

0

0

Remarks

Do not advance until starting N = 1400.

Do not advance until starting N = 1400.

Timer adjustment_02

Pump speed

r/min

-

Advance angle

deg.

0.7

0.7

0.7

Remarks

Measure the actual speed, stop

Measure the actual speed, stop

Test data Ex:

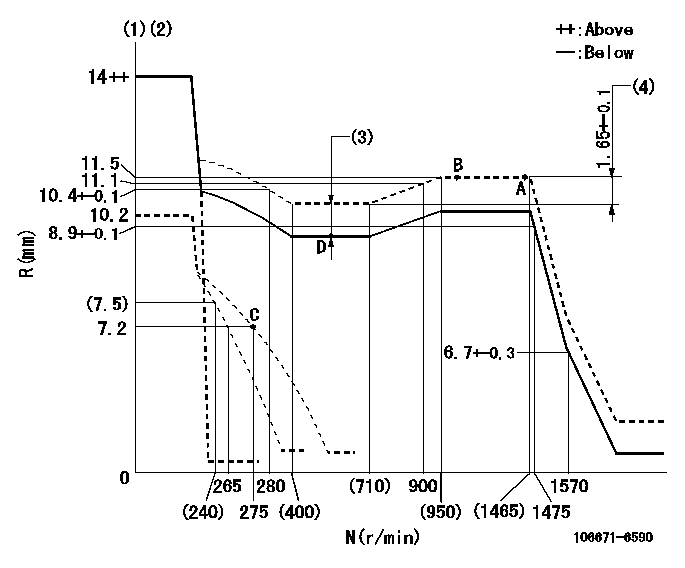

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)Boost compensator stroke: BCL

(4)Rack difference between N = N1 and N = N2

----------

K=8 BCL=2.15+-0.1mm N1=1450r/min N2=600r/min

----------

----------

K=8 BCL=2.15+-0.1mm N1=1450r/min N2=600r/min

----------

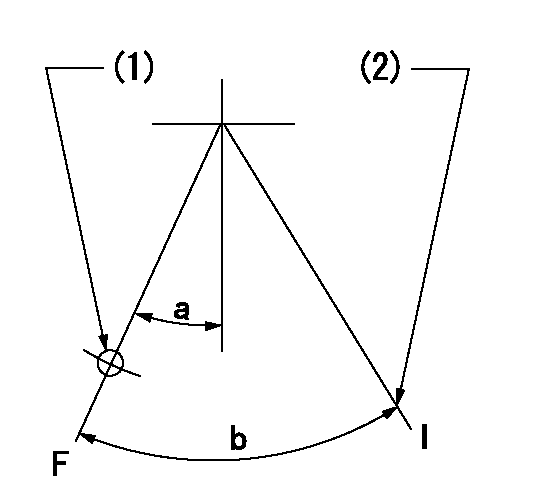

Speed control lever angle

F:Full speed

I:Idle

(1)Use the hole at R = aa

(2)Stopper bolt setting

----------

aa=70mm

----------

a=19deg+-5deg b=(34deg)+-5deg

----------

aa=70mm

----------

a=19deg+-5deg b=(34deg)+-5deg

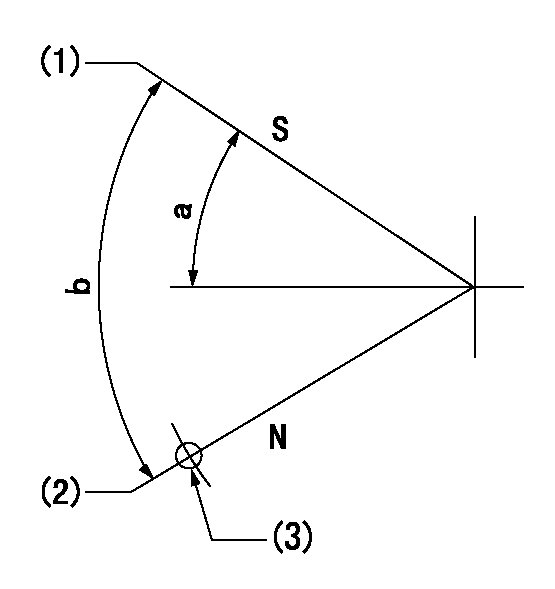

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Rack position = aa, speed = bb (stamp at delivery)

(2)Normal

(3)Use the hole above R = cc

----------

aa=1-0.5mm bb=0r/min cc=33mm

----------

a=25.5deg+-5deg b=70deg+-5deg

----------

aa=1-0.5mm bb=0r/min cc=33mm

----------

a=25.5deg+-5deg b=70deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Positions of coupling's threaded installation holes at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(50deg)

----------

----------

a=(50deg)

Information:

Introduction

The problem that is identified below does not have a permanent solution. Until a permanent solution is known, use the solution that is listed below.Problem

A significant amount of HEUI pumps and injectors have been returned, but no cause of failure can be determined.Solution

Diagnostic procedures have been updated and have been incorporated into the following publications:

Special Instruction, REHS3819, "Procedure for Troubleshooting and Cleaning the Oil Rail System for the Hydraulic Electronic Unit Injector (HEUI)"

Troubleshooting, "Injection Actuation Pressure - Test"Note: These publications have been translated into Mandarin and Spanish.In addition, a new troubleshooting checklist is included with all service repair for HUEI pumps and HEUI injectors. The checklist is a summary of the diagnostic procedure steps to be confirmed before a suspect component is replaced. The checklist must be completed and returned with the suspect components in order to aid engineering to determine the cause of failure.Following the instructions step-by-step is critical in order to diagnose the failed component correctly. Do not skip steps in the procedures. Skipping steps in the procedure will lead to incorrect diagnosis of the problem.

The problem that is identified below does not have a permanent solution. Until a permanent solution is known, use the solution that is listed below.Problem

A significant amount of HEUI pumps and injectors have been returned, but no cause of failure can be determined.Solution

Diagnostic procedures have been updated and have been incorporated into the following publications:

Special Instruction, REHS3819, "Procedure for Troubleshooting and Cleaning the Oil Rail System for the Hydraulic Electronic Unit Injector (HEUI)"

Troubleshooting, "Injection Actuation Pressure - Test"Note: These publications have been translated into Mandarin and Spanish.In addition, a new troubleshooting checklist is included with all service repair for HUEI pumps and HEUI injectors. The checklist is a summary of the diagnostic procedure steps to be confirmed before a suspect component is replaced. The checklist must be completed and returned with the suspect components in order to aid engineering to determine the cause of failure.Following the instructions step-by-step is critical in order to diagnose the failed component correctly. Do not skip steps in the procedures. Skipping steps in the procedure will lead to incorrect diagnosis of the problem.