Information injection-pump assembly

BOSCH

9 400 613 008

9400613008

ZEXEL

106671-6452

1066716452

ISUZU

1156033342

1156033342

Rating:

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

Fuel Injection Pump 1156033342 for Isuzu Engine 6HK1 Hitachi Excavator ZX330-3G ZX350-5G ZX350H ZX350K ZX350W ZX500W ZX360LC-HHE

DIGERTECH Part number:1156033342 || Application: for Isuzu Engine 6HK1 Hitachi Excavator ZX330-3G ZX350-5G ZX350H ZX350K ZX350W ZX500W ZX360LC-HHE

DIGERTECH Part number:1156033342 || Application: for Isuzu Engine 6HK1 Hitachi Excavator ZX330-3G ZX350-5G ZX350H ZX350K ZX350W ZX500W ZX360LC-HHE

Fuel Injection Pump Fits Compatible with Isuzu Engine 6HK1 106671-6452 106067-6251 1066716452

EWAIDI Part Number: 106671-6452 106067-6251 1066716452 Note: Please check the fitment carefully before purchase. Or just tell us the part number you need. || Part Name: Fuel Injection Pump || Suitable for use with the Isuzu Engine 6HK1. || Package included: 1 piece of the Fuel Injection Pump with model numbers 106671-6452, 106067-6251, and 1066716452. This essential component is designed to efficiently deliver fuel to the engine for optimal performance. A high-quality and durable product that is essential for maintaining the proper functioning of your vehicle.

EWAIDI Part Number: 106671-6452 106067-6251 1066716452 Note: Please check the fitment carefully before purchase. Or just tell us the part number you need. || Part Name: Fuel Injection Pump || Suitable for use with the Isuzu Engine 6HK1. || Package included: 1 piece of the Fuel Injection Pump with model numbers 106671-6452, 106067-6251, and 1066716452. This essential component is designed to efficiently deliver fuel to the engine for optimal performance. A high-quality and durable product that is essential for maintaining the proper functioning of your vehicle.

Compatible with Isuzu Engine 6HK1 Compatible Fuel Injection Pump 106671-6452 106067-6251 1066716452

EWAIDI Part Number: 106671-6452 106067-6251 1066716452 Note: Please check the fitment carefully before purchase. Or just tell us the part number you need. || Part Name: Fuel Injection Pump || Suitable for use with the Isuzu Engine 6HK1 || Package included: 1 piece of the Fuel Injection Pump with model numbers 106671-6452, 106067-6251, and 1066716452. This essential component is designed to efficiently deliver fuel to the engine for optimal performance. A high-quality and durable product that is essential for maintaining the proper functioning of your vehicle.

EWAIDI Part Number: 106671-6452 106067-6251 1066716452 Note: Please check the fitment carefully before purchase. Or just tell us the part number you need. || Part Name: Fuel Injection Pump || Suitable for use with the Isuzu Engine 6HK1 || Package included: 1 piece of the Fuel Injection Pump with model numbers 106671-6452, 106067-6251, and 1066716452. This essential component is designed to efficiently deliver fuel to the engine for optimal performance. A high-quality and durable product that is essential for maintaining the proper functioning of your vehicle.

You can express buy:

USD 969.65

01-07-2025

01-07-2025

Fuel Injection Pump Assy New 6HK1 for Isuzu ZEXEL 1156033345 1156033342 for Excavator Manufacturing Plant

USD 1207.2

13-05-2025

13-05-2025

Long Time Aftersale Service Fuel Injection Pump 106671-6452 For Isuzu 6HK1 Engine Spare Parts

Images:

USD 1328.62

[14-Jun-2025]

USD 2028.98

[28-Apr-2025]

Service parts 106671-6452 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

1-15300-389-1

12.

Open Pre:MPa(Kqf/cm2)

18.1{185}/22.1{225}

14.

NOZZLE

Include in #1:

106671-6452

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 400 613 008

9400613008

ZEXEL

106671-6452

1066716452

ISUZU

1156033342

1156033342

Zexel num

Bosch num

Firm num

Name

106671-6452

9 400 613 008

1156033342 ISUZU

INJECTION-PUMP ASSEMBLY

6HK1-XQA K 14CA INJECTION PUMP ASSY PE6P,6PD PE

6HK1-XQA K 14CA INJECTION PUMP ASSY PE6P,6PD PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

134424-4320

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

255

255

255

Tester oil delivery pressure

kgf/cm2

2.6

2.6

2.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

2.9

2.87

2.93

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.75 60.25

Cal 1-5 deg. 60 59.75 60.25

Difference between angles 2

Cal 1-3 deg. 120 119.75 120.25

Cal 1-3 deg. 120 119.75 120.25

Difference between angles 3

Cal 1-6 deg. 180 179.75 180.25

Cal 1-6 deg. 180 179.75 180.25

Difference between angles 4

Cyl.1-2 deg. 240 239.75 240.25

Cyl.1-2 deg. 240 239.75 240.25

Difference between angles 5

Cal 1-4 deg. 300 299.75 300.25

Cal 1-4 deg. 300 299.75 300.25

Injection quantity adjustment

Adjusting point

A

Rack position

12.8

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

133.5

132.5

134.5

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the lever

*

Boost pressure

kPa

171

171

Boost pressure

mmHg

1280

1280

Injection quantity adjustment_02

Adjusting point

-

Rack position

7.5+-0.5

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

9.5

6.3

12.7

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Injection quantity adjustment_03

Adjusting point

E

Rack position

13++

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

155

145

165

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Rack limit

*

Boost compensator adjustment

Pump speed

r/min

550

550

550

Rack position

10.8

Boost pressure

kPa

92

88

96

Boost pressure

mmHg

690

660

720

Boost compensator adjustment_02

Pump speed

r/min

550

550

550

Rack position

11.2

Boost pressure

kPa

157

150.3

163.7

Boost pressure

mmHg

1180

1130

1230

Timer adjustment

Pump speed

r/min

1200++

Advance angle

deg.

0

0

0

Remarks

Do not advance until starting N = 1200.

Do not advance until starting N = 1200.

Timer adjustment_02

Pump speed

r/min

-

Advance angle

deg.

0.7

0.7

0.7

Remarks

Measure the actual speed, stop

Measure the actual speed, stop

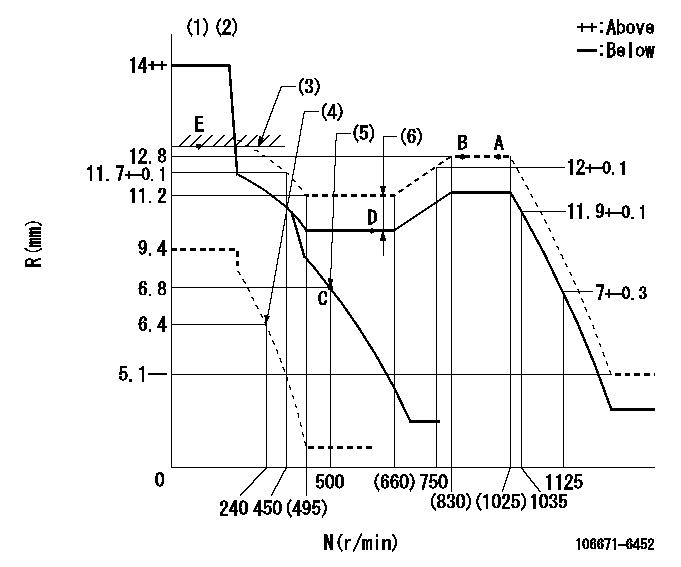

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

(4)Set idle sub-spring

(5)Main spring setting

(6)Boost compensator stroke: BCL

----------

K=12 BCL=0.4+-0.1mm

----------

----------

K=12 BCL=0.4+-0.1mm

----------

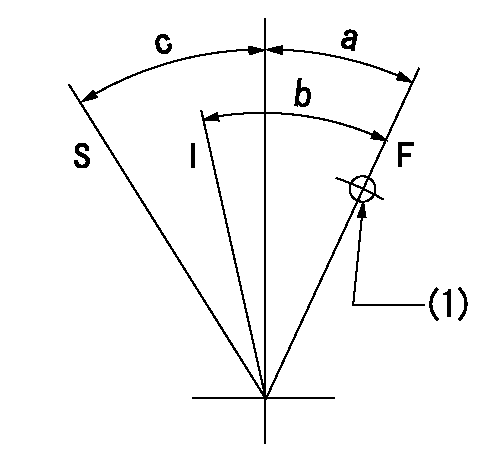

Speed control lever angle

F:Full speed

I:Idle

S:Stop

(1)Use the hole at R = aa

----------

aa=70mm

----------

a=3deg+-5deg b=18deg+-5deg c=31deg+-3deg

----------

aa=70mm

----------

a=3deg+-5deg b=18deg+-5deg c=31deg+-3deg

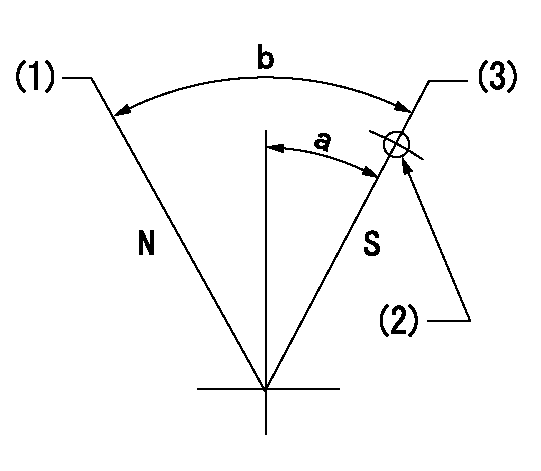

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Normal

(2)Use the hole at R = aa

(3)Rack position bb, pump speed cc (seal at delivery)

----------

aa=23mm bb=1-0.5mm cc=0r/min

----------

a=15deg+-5deg b=70deg+-5deg

----------

aa=23mm bb=1-0.5mm cc=0r/min

----------

a=15deg+-5deg b=70deg+-5deg

0000001501 TAMPER PROOF

Tamperproofing-equipped boost compensator cover installation procedure

(A) After adjusting the boost compensator, tighten the bolts to remove the heads.

(1)Before adjusting the governor and the boost compensator, tighten the screw to the specified torque.

(Tightening torque T = T1 maximum)

(2)After adjusting the governor and the boost compensator, tighten to the specified torque to break off the bolt heads.

(Tightening torque T = T2)

----------

T1=2.5N-m(0.25kgf-m) T2=2.9~4.4N-m(0.3~0.45kgf-m)

----------

----------

T1=2.5N-m(0.25kgf-m) T2=2.9~4.4N-m(0.3~0.45kgf-m)

----------

Timing setting

(1)Pump vertical direction

(2)Position of timer's threaded installation hole at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=9deg

----------

a=(50deg)

----------

aa=9deg

----------

a=(50deg)

Information:

Illustration 1 g00564355

7W-2743 Electronic Speed Switch (ESS)

(1) Push button for Overspeed Verification

(2) Reset button

(3) Overspeed indicator lamp

(4) Seal screw plug for adjusting the engine overspeed

(5) Seal screw plug for adjusting the crank terminate speed

(6) Seal screw plug for adjusting the oil step pressure speed setting The procedure for the magnetic pickup test will determine if the operation of the magnetic pickup is correct.

Connect a 6V-7070 Digital Multimeter to the "COM" terminal and the "SIG" terminal. The terminals are (ESS-3)and (ESS-4) of the ESS. Set the meter voltage scale to a scale that is greater than 1.5 VAC. Start the engine. Run the engine at low idle or 600 rpm. Choose the one that is larger. If the voltage that is measured is 1.5 VAC or more, the operation of the magnetic pickup is correct. If the voltage is less than 1.5 VAC, go to Step 2.

Stop the engine. Disconnect the wiring for the magnetic pickup at the plug-in connector. Connect the voltmeter to the connector terminals of the magnetic pickup. Start the engine. Run the engine at low idle or 600 rpm. Choose the one that is larger. If the voltage that is measured is 1.5 VAC or more, repair the wiring that is between the magnetic pickup and the ESS. If the voltage is less than 1.5 VAC, go to Step 3.

Illustration 2 g00564913

Magnetic pickup

(1) Clearance

(2) Magnetic pickup

(3) Wires to the connector

(4) Locknut

(5) Flywheel housing

(6) Ring gear

Loosen locknut (4) and turn magnetic pickup (2) in the counterclockwise direction in order to remove magnetic pickup (2) from flywheel housing (5). Turn the flywheel until a gear tooth of ring gear (6) is directly in the center of the threaded hole for magnetic pickup (2). Install magnetic pickup (2) in flywheel housing (5).

Turn magnetic pickup (2) in the clockwise direction until the end of magnetic pickup (2) slightly touches the gear tooth. Turn the magnetic pickup for one-half turn in the counterclockwise direction in order to set correct clearance (1). Tighten locknut (4) to a torque of 45 7 N m (33 5 lb ft). Note: Do not allow the magnetic pickup to turn while the locknut is tightened.

Repeat Step 2. If the voltage is still less than 1.5 VAC, replace the magnetic pickup.

Have questions with 106671-6452?

Group cross 106671-6452 ZEXEL

Isuzu

Isuzu

106671-6452

9 400 613 008

1156033342

INJECTION-PUMP ASSEMBLY

6HK1-XQA

6HK1-XQA