Information injection-pump assembly

ZEXEL

106671-6292

1066716292

ISUZU

1156032173

1156032173

Rating:

Service parts 106671-6292 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

1-15300-332-0

12.

Open Pre:MPa(Kqf/cm2)

17.7{180}/22.1{225}

15.

NOZZLE SET

Include in #1:

106671-6292

as INJECTION-PUMP ASSEMBLY

Cross reference number

ZEXEL

106671-6292

1066716292

ISUZU

1156032173

1156032173

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131424-8620

Overflow valve opening pressure

kPa

206

172

240

Overflow valve opening pressure

kgf/cm2

2.1

1.75

2.45

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

4.5

4.47

4.53

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.75 60.25

Cal 1-5 deg. 60 59.75 60.25

Difference between angles 2

Cal 1-3 deg. 120 119.75 120.25

Cal 1-3 deg. 120 119.75 120.25

Difference between angles 3

Cal 1-6 deg. 180 179.75 180.25

Cal 1-6 deg. 180 179.75 180.25

Difference between angles 4

Cyl.1-2 deg. 240 239.75 240.25

Cyl.1-2 deg. 240 239.75 240.25

Difference between angles 5

Cal 1-4 deg. 300 299.75 300.25

Cal 1-4 deg. 300 299.75 300.25

Injection quantity adjustment

Adjusting point

-

Rack position

11.3

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

149

147

151

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

H

Rack position

6.4+-0.5

Pump speed

r/min

290

290

290

Average injection quantity

mm3/st.

10

6.8

13.2

Max. variation between cylinders

%

0

-13

13

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(11.3)

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

149

147

151

Basic

*

Fixing the lever

*

Boost pressure

kPa

60

60

Boost pressure

mmHg

450

450

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1+0.65

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

161

155

167

Fixing the lever

*

Boost pressure

kPa

60

60

Boost pressure

mmHg

450

450

Boost compensator adjustment

Pump speed

r/min

500

500

500

Rack position

R2-1.75

Boost pressure

kPa

4

4

6.7

Boost pressure

mmHg

30

30

50

Boost compensator adjustment_02

Pump speed

r/min

500

500

500

Rack position

R2(R1-0.

45)

Boost pressure

kPa

46.7

46.7

46.7

Boost pressure

mmHg

350

350

350

Timer adjustment

Pump speed

r/min

850--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

800

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

875

Advance angle

deg.

1.5

1

2

Remarks

Finish

Finish

Test data Ex:

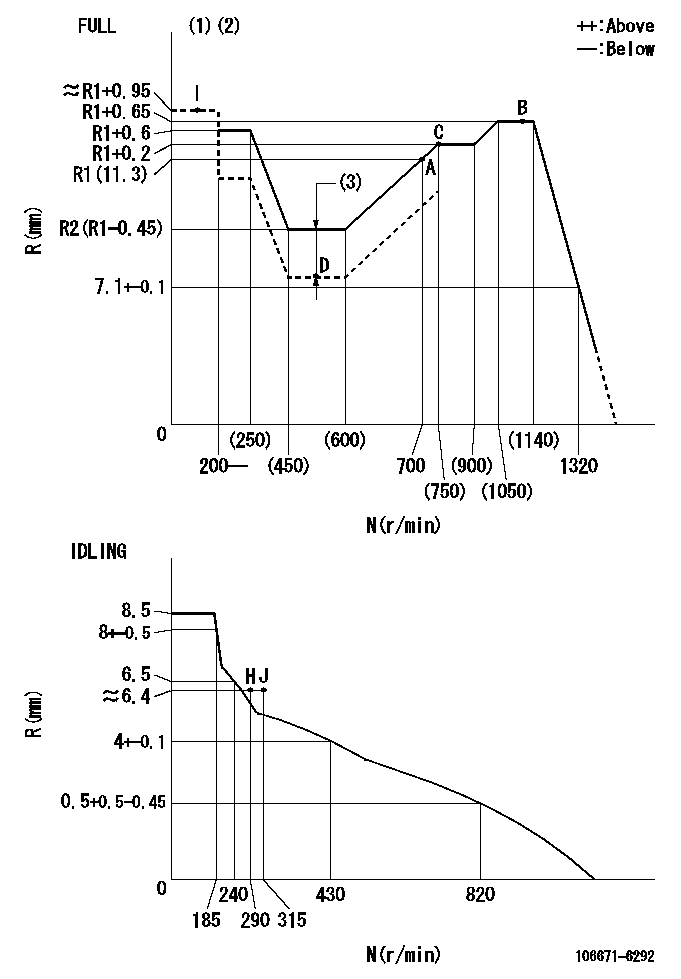

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)Tolerance for racks not indicated: +-0.05mm.

(3)Boost compensator stroke: BCL

----------

T1=AE45 BCL=1.75+-0.1mm

----------

----------

T1=AE45 BCL=1.75+-0.1mm

----------

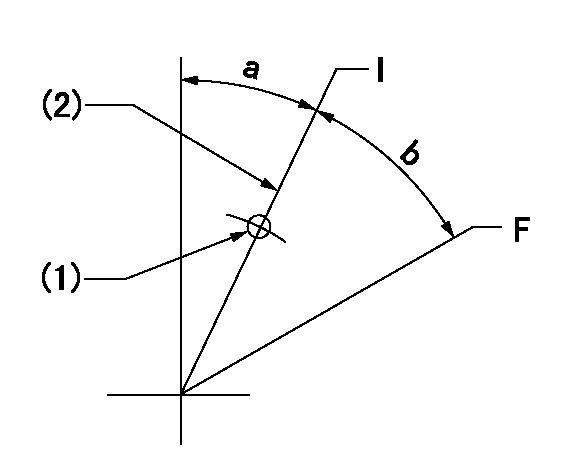

Speed control lever angle

F:Full speed

I:Idle

(1)Use the pin at R = aa

(2)Stopper bolt set position 'H'

----------

aa=35mm

----------

a=27deg+-5deg b=32.5deg+-3deg

----------

aa=35mm

----------

a=27deg+-5deg b=32.5deg+-3deg

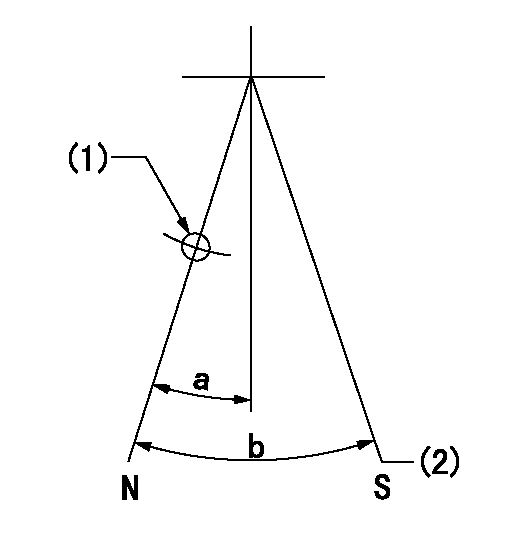

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Use the pin at R = aa

(2)Set the stopper bolt so that speed = bb and rack position = cc. (Confirm non-injection.)

----------

aa=40mm bb=0r/min cc=1.5+-0.3mm

----------

a=22deg+-5deg b=41deg+-5deg

----------

aa=40mm bb=0r/min cc=1.5+-0.3mm

----------

a=22deg+-5deg b=41deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of timer's threaded hole at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=10deg

----------

a=(40deg)

----------

aa=10deg

----------

a=(40deg)

Information:

ACTION REQUIRED

Do not order the 601-8546 and 601-8547 Hoses. The new hoses have been direct shipped to the dealership prior to the release of this Service Letter program.

If you have not received the parts, the parts received are damaged, or if you have any questions you will need to work with your Dealer TC to submit the information or question through CPI Feedback within the Service Information Management System (SIMSi).

Give the information to your Dealer Technical Communicator (TC) along with this service letter program number and CPI number 472555.

Request the Dealer TC to submit the CPI Feedback.

Refer to the attached Rework Procedure.

OWNER NOTIFICATION

Owners in the following countries will receive the attached Owner Notification:

US

Canada

SERVICE CLAIM ALLOWANCES

Caterpillar Dealer Suggested Customer Suggested

Parts % Labor Hrs% Parts % Labor Hrs% Parts % Labor Hrs%

100% 100% 0% 0% 0% 0%

This is a 1.5-hour job

Note: $60 US Dollars are allowed for 10 Liters of coolant.

PARTS DISPOSITION

Handle the parts in accordance with your Warranty Bulletin on warranty parts handling.

MAKE EVERY EFFORT TO COMPLETE THIS PROGRAM AS SOON AS POSSIBLE.

EXAMPLE COPY OF OWNER NOTIFICATION

XYZ Corporation

3240 Arrow Drive

Anywhere, YZ 99999

PRIORITY - PRODUCT IMPROVEMENT PROGRAM FOR REPLACING THE DEF INJECTOR COOLANT HOSES

MODELS INVOLVED - CERTAIN 313 AND 315 NGH EXCAVATORS

Dear Cat Product Owner:

The existing coolant hoses need to be replaced on the products listed below. The existing hoses can leak water and/or burst. You will not be charged for the service performed.

Contact your local Cat dealer immediately to schedule this service. The dealer will advise you of the time required to complete this service.

If you are no longer the owner of this product(s), please contact your local Cat dealer so that our records can be updated. Please refer the dealer to their Service Letter dated 01Jul2020 when scheduling this service.

We regret the inconvenience this may cause you, and urge you to have this service performed as soon as possible to prevent unscheduled downtime.

Caterpillar Inc.

Identification #(s)

Attached to 01Jul2020 Service Letter

Rework Procedure

1. Confirm the machine/engine components/coolant are cooled down for safety.

2. Drain coolant (approximately 10L) to avoid spilling out from hoses during replacement.

3. Removed the strap on hose. Refer to Image1.3.1.

Image1.3.1

4. Loosen the clamps and remove the hoses (both inlet and outlet). Refer to Image1.4.1.

Image1.4.1

5. Install new parts. Refer to Images1.5.1 and 1.5.2.

Image1.5.1

Image1.5.2

6. Fill the coolant and check for leakage from the hoses.