Information injection-pump assembly

ZEXEL

106671-6282

1066716282

ISUZU

1156032163

1156032163

Rating:

Cross reference number

ZEXEL

106671-6282

1066716282

ISUZU

1156032163

1156032163

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131424-8620

Overflow valve opening pressure

kPa

206

172

240

Overflow valve opening pressure

kgf/cm2

2.1

1.75

2.45

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

4.5

4.47

4.53

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.75 60.25

Cal 1-5 deg. 60 59.75 60.25

Difference between angles 2

Cal 1-3 deg. 120 119.75 120.25

Cal 1-3 deg. 120 119.75 120.25

Difference between angles 3

Cal 1-6 deg. 180 179.75 180.25

Cal 1-6 deg. 180 179.75 180.25

Difference between angles 4

Cyl.1-2 deg. 240 239.75 240.25

Cyl.1-2 deg. 240 239.75 240.25

Difference between angles 5

Cal 1-4 deg. 300 299.75 300.25

Cal 1-4 deg. 300 299.75 300.25

Injection quantity adjustment

Adjusting point

-

Rack position

11.3

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

149

147

151

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

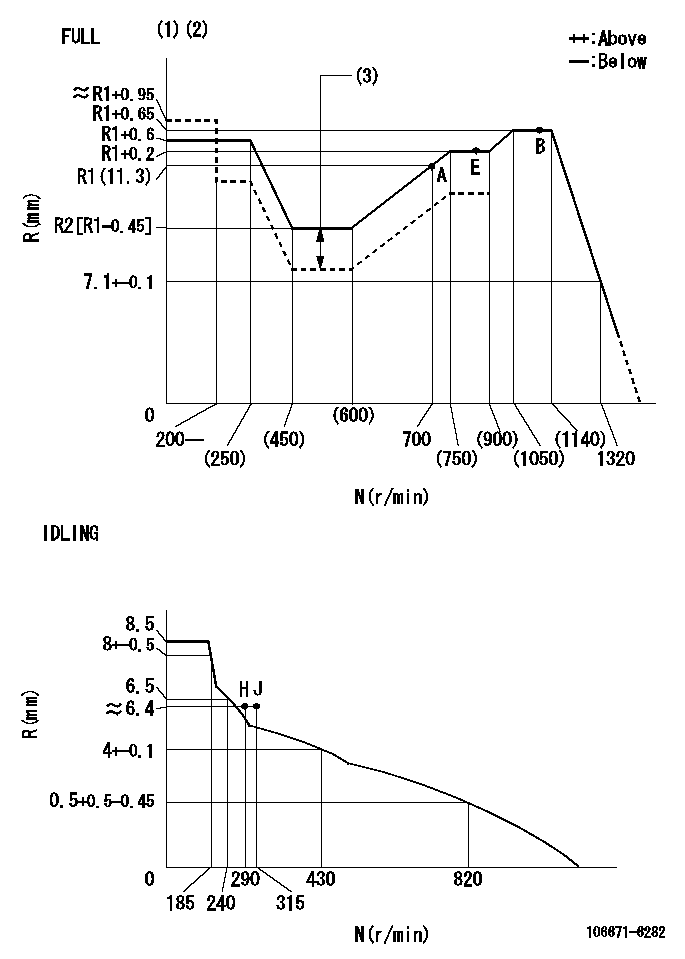

Injection quantity adjustment_02

Adjusting point

H

Rack position

6.4+-0.5

Pump speed

r/min

290

290

290

Average injection quantity

mm3/st.

10

6.8

13.2

Max. variation between cylinders

%

0

-13

13

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(11.3)

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

149

147

151

Basic

*

Fixing the lever

*

Boost pressure

kPa

60

60

Boost pressure

mmHg

450

450

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1+0.65

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

161

155

167

Fixing the lever

*

Boost pressure

kPa

60

60

Boost pressure

mmHg

450

450

Injection quantity adjustment_05

Adjusting point

E

Rack position

R1+0.2

Pump speed

r/min

800

800

800

Average injection quantity

mm3/st.

149

143

155

Fixing the lever

*

Boost pressure

kPa

60

60

Boost pressure

mmHg

450

450

Boost compensator adjustment

Pump speed

r/min

500

500

500

Rack position

R2-1.75

Boost pressure

kPa

4

4

6.7

Boost pressure

mmHg

30

30

50

Boost compensator adjustment_02

Pump speed

r/min

500

500

500

Rack position

R2[R1-0.

45]

Boost pressure

kPa

46.7

46.7

46.7

Boost pressure

mmHg

350

350

350

Timer adjustment

Pump speed

r/min

850--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

800

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

875

Advance angle

deg.

1.5

1

2

Remarks

Finish

Finish

Test data Ex:

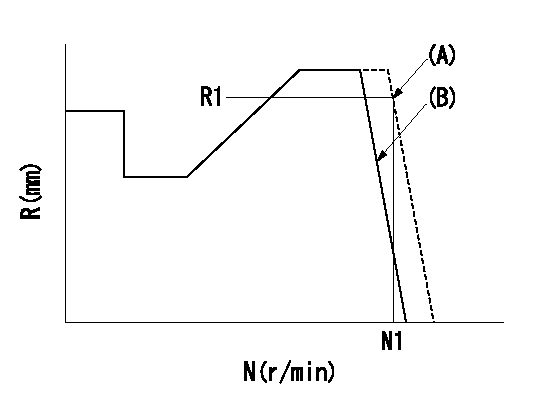

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)Tolerance for racks not indicated: +-0.05mm.

(3)Boost compensator stroke: BCL

----------

T1=AE45 BCL=1.75+-0.1mm

----------

----------

T1=AE45 BCL=1.75+-0.1mm

----------

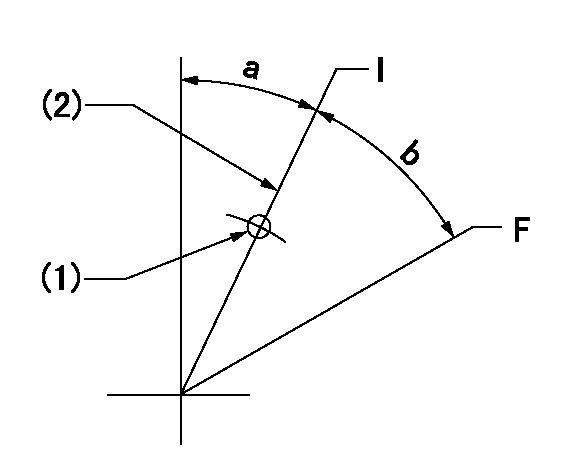

Speed control lever angle

F:Full speed

I:Idle

(1)Use the pin at R = aa

(2)Stopper bolt setting

----------

aa=35mm

----------

a=27deg+-5deg b=32.5deg+-3deg

----------

aa=35mm

----------

a=27deg+-5deg b=32.5deg+-3deg

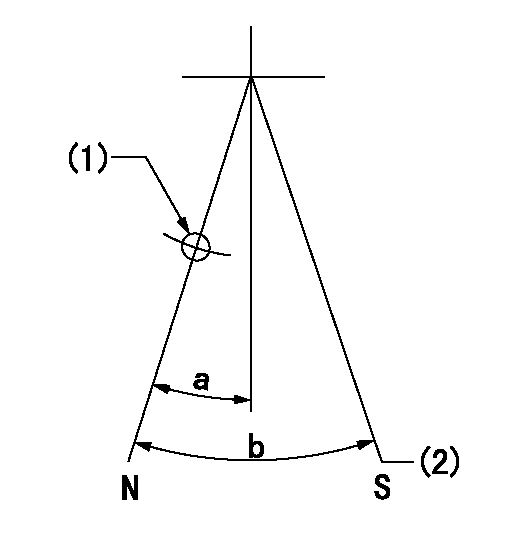

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Use the pin at R = aa

(2)Set the stopper bolt so that speed = bb and rack position = cc. (Confirm non-injection.)

----------

aa=40mm bb=0r/min cc=1.5+-0.3mm

----------

a=22deg+-5deg b=41deg+-5deg

----------

aa=40mm bb=0r/min cc=1.5+-0.3mm

----------

a=22deg+-5deg b=41deg+-5deg

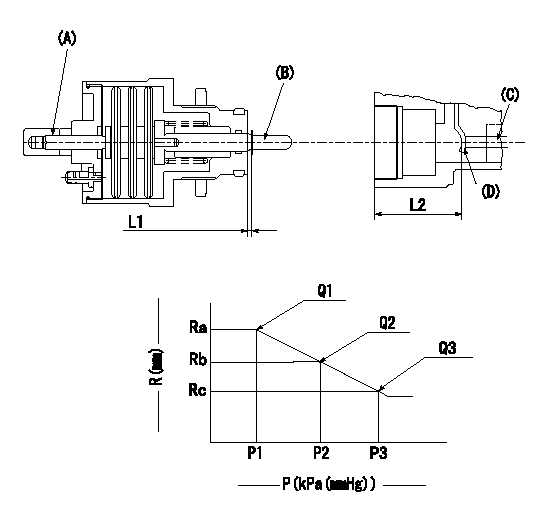

0000001501 ACS

(A) Set screw

(B) Push rod 1

(C) Push rod 2

(D) Lever

1. Aneroid compensator unit adjustment

(1)Screw in (A) to obtain L1.

(2)Select C so that dimension L2 can be obtained.

2. Adjustment when mounting the governor.

(1)Set the speed of the pump to N1 r/min and fix the control lever at the full set position.

(2)Set to full boost.

(3)Screw in the aneroid compensator body to obtain the performance shown in the graph above.

(4)As there is hysterisis, measure when the absolute pressure drops.

(5)Hysterisis must not exceed rack position = h1.

----------

N1=800r/min L1=1.5+-0.5mm L2=37.5+-0.5mm h1=0.15mm

----------

Ra=R3[R1+0.2]mm Rb=(R3-0.4)mm Rc=R3-0.75mm P1=(89.8)+-2.7kPa((674)+-20mmHg) P2=79.4+-2.7kPa(596+-20mmHg) P3=70.1+-0.7kPa(526+-5mmHg) Q1=(149)+-3cm3/1000st Q2=(138.5)cm3/1000st Q3=(129)+-3cm3/1000st

----------

N1=800r/min L1=1.5+-0.5mm L2=37.5+-0.5mm h1=0.15mm

----------

Ra=R3[R1+0.2]mm Rb=(R3-0.4)mm Rc=R3-0.75mm P1=(89.8)+-2.7kPa((674)+-20mmHg) P2=79.4+-2.7kPa(596+-20mmHg) P3=70.1+-0.7kPa(526+-5mmHg) Q1=(149)+-3cm3/1000st Q2=(138.5)cm3/1000st Q3=(129)+-3cm3/1000st

0000001601 TAMPER PROOF

(A): Rotation tamper proof

(B): Full-speed setting

1. Back off the full-speed set bolt.

2. Confirm that the tamper setting position is N1, R1, Q1.

3. At that time, record the angle of the speed lever.

4. After confirming the above setting, set full speed.

----------

N1=1440r/min R1=(7.1)mm Q1=-

----------

----------

N1=1440r/min R1=(7.1)mm Q1=-

----------

Timing setting

(1)Pump vertical direction

(2)Position of timer's threaded hole at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=10deg

----------

a=(50deg)

----------

aa=10deg

----------

a=(50deg)

Information:

PROBLEM

The diesel oxidation catalysts needs to be reworked or replaced on certain 3512E Petroleum Engines. The existing diesel oxidation catalysts can crack on the top panel and cause an exhaust leak.

AFFECTED PRODUCT

Model Identification Number

3512E NG400100-00127

NG500100-00130

PARTS NEEDED

Qty

Part Number Description

2 3031968 GASKET

4 3460335 CLAMP-BAND

4 5365400 PLATE (Before Failure-See Action Required)

2 5492046 MODULE AR-EXH (After Failure-See Action Required)

In order to allow equitable parts availability to all participating dealers, please limit your initial parts order to not exceed 45% of dealership population. This is an initial order recommendation only, and the ultimate responsibility for ordering the total number of parts needed to satisfy the program lies with the dealer.

ACTION REQUIRED

There is currently a limited supply of parts available for this program. The 549-2046 Part Name is frozen and allocation will be manually prioritized until sufficient quantities are available. Please work with your Customer Service Representative for parts availability.

Refer to the Safety Section in the Operation and Maintenance Manual prior to conducting any service work.

Inspect the existing diesel oxidation catalysts for cracks.

If no cracks are present, refer to Special Instruction, M0116373 for welding rails onto the top of the diesel oxidation catalysts.

If cracks are present, the diesel oxidation catalysts will need to be replaced.

OWNER NOTIFICATION

Owners in the following countries will receive the attached Owner Notification:

US

Canada

SERVICE CLAIM ALLOWANCES

Caterpillar Dealer Suggested Customer Suggested

Parts % Labor Hrs% Parts % Labor Hrs% Parts % Labor Hrs%

100% 100% 0% 0% 0% 0%

This is a 6.0-hour job

6.0 hours for after failure for replacing DOC's.

10.0 Hours for before failure for R&I of DOC's and welding.

PARTS DISPOSITION

Handle the parts in accordance with your Warranty Bulletin on warranty parts handling.

MAKE EVERY EFFORT TO COMPLETE THIS PROGRAM AS SOON AS POSSIBLE.

EXAMPLE COPY OF OWNER NOTIFICATION

XYZ Corporation

3240 Arrow Drive

Anywhere, YZ 99999

PRIORITY - PRODUCT IMPROVEMENT PROGRAM FOR REWORKING OR REPLACING THE DIESEL OXIDATION CATALYSTS

MODELS INVOLVED - CERTAIN 3512E PETROLEUM ENGINES

Dear Cat Product Owner:

The Diesel Oxidation Catalysts need to be reworked or replaced on the products listed below. The existing Diesel Oxidation Catalysts can crack on the top panel and cause an exhaust leak. You will not be charged for the service performed.

Contact your local Cat dealer immediately to schedule this service. The dealer will advise you of the time required to complete this service.

If you are no longer the owner of this product(s), please contact your local Cat dealer so that our records can be updated. Please refer the dealer to their Service Letter dated 12Mar2020 when scheduling this service.

We regret the inconvenience this may cause you, and urge you to have this service performed as soon as possible to prevent unscheduled downtime.

Caterpillar Inc.

Identification #(s)

Attached to 12Mar2020 Service Letter