Information injection-pump assembly

BOSCH

F 019 Z10 004

f019z10004

ZEXEL

106671-6262

1066716262

ISUZU

1156032143

1156032143

Rating:

Service parts 106671-6262 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

17.7{180}/22.1{225}

15.

NOZZLE SET

Include in #1:

106671-6262

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

F 019 Z10 004

f019z10004

ZEXEL

106671-6262

1066716262

ISUZU

1156032143

1156032143

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131424-8620

Overflow valve opening pressure

kPa

206

172

240

Overflow valve opening pressure

kgf/cm2

2.1

1.75

2.45

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

4.5

4.47

4.53

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.75 60.25

Cal 1-5 deg. 60 59.75 60.25

Difference between angles 2

Cal 1-3 deg. 120 119.75 120.25

Cal 1-3 deg. 120 119.75 120.25

Difference between angles 3

Cal 1-6 deg. 180 179.75 180.25

Cal 1-6 deg. 180 179.75 180.25

Difference between angles 4

Cyl.1-2 deg. 240 239.75 240.25

Cyl.1-2 deg. 240 239.75 240.25

Difference between angles 5

Cal 1-4 deg. 300 299.75 300.25

Cal 1-4 deg. 300 299.75 300.25

Injection quantity adjustment

Adjusting point

-

Rack position

11.3

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

149

147

151

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

H

Rack position

6.4+-0.5

Pump speed

r/min

290

290

290

Average injection quantity

mm3/st.

10

6.8

13.2

Max. variation between cylinders

%

0

-13

13

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(11.3)

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

149

147

151

Basic

*

Fixing the lever

*

Boost pressure

kPa

60

60

Boost pressure

mmHg

450

450

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1+0.65

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

161

155

167

Fixing the lever

*

Boost pressure

kPa

60

60

Boost pressure

mmHg

450

450

Boost compensator adjustment

Pump speed

r/min

500

500

500

Rack position

R2-1.75

Boost pressure

kPa

4

4

6.7

Boost pressure

mmHg

30

30

50

Boost compensator adjustment_02

Pump speed

r/min

500

500

500

Rack position

R2(R1-0.

45)

Boost pressure

kPa

46.7

46.7

46.7

Boost pressure

mmHg

350

350

350

Timer adjustment

Pump speed

r/min

850--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

800

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

875

Advance angle

deg.

1.5

1

2

Remarks

Finish

Finish

Test data Ex:

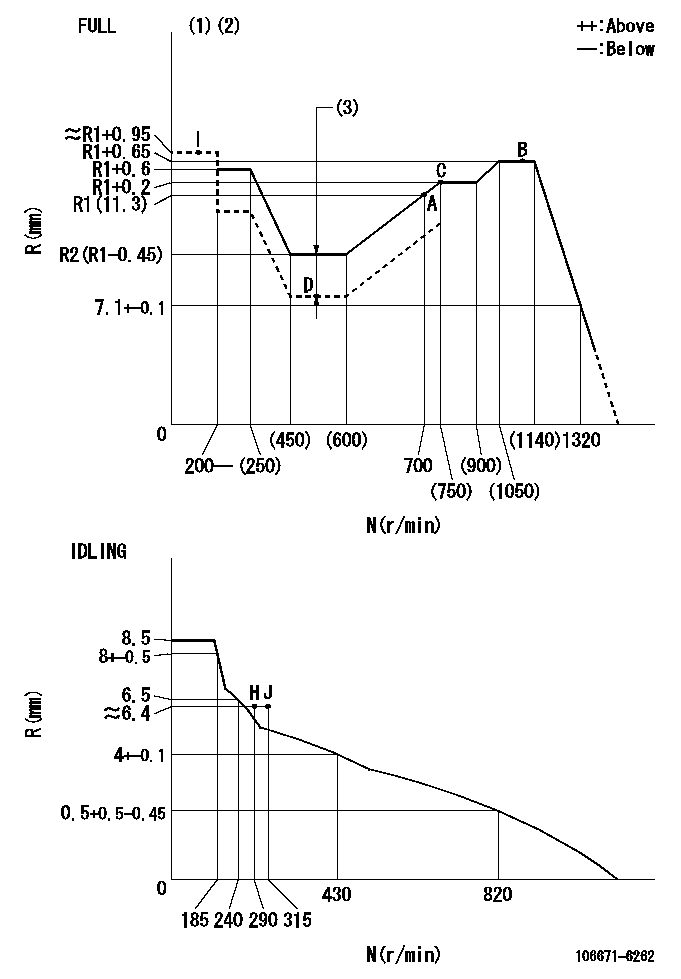

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)Tolerance for racks not indicated: +-0.05mm.

(3)Boost compensator stroke: BCL

----------

T1=AE45 BCL=1.75+-0.1mm

----------

----------

T1=AE45 BCL=1.75+-0.1mm

----------

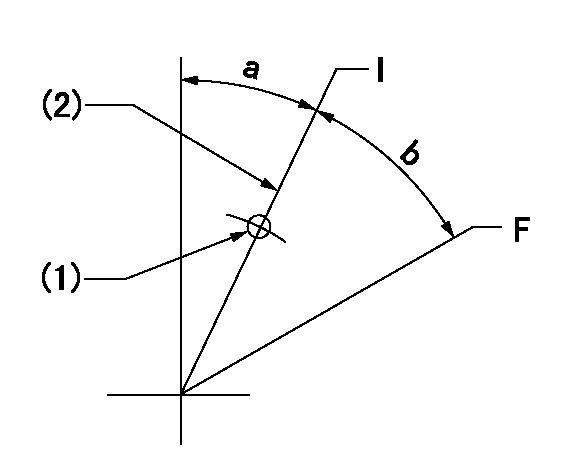

Speed control lever angle

F:Full speed

I:Idle

(1)Use the pin at R = aa

(2)Stopper bolt set position 'H'

----------

aa=35mm

----------

a=27deg+-5deg b=32.5deg+-3deg

----------

aa=35mm

----------

a=27deg+-5deg b=32.5deg+-3deg

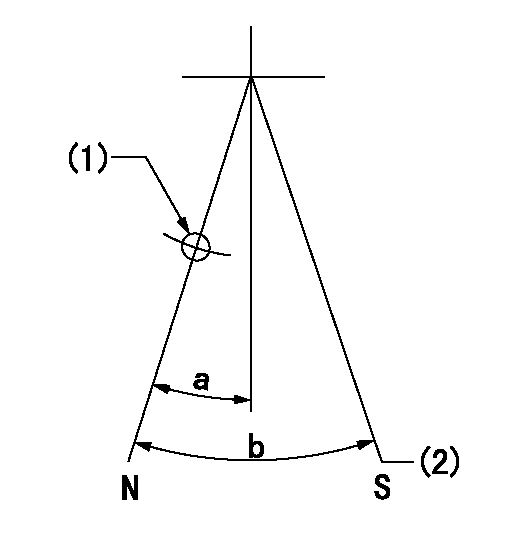

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Use the pin at R = aa

(2)Set the stopper bolt so that speed = bb and rack position = cc. (Confirm non-injection.)

----------

aa=40mm bb=0r/min cc=1.5+-0.3mm

----------

a=22deg+-5deg b=41deg+-5deg

----------

aa=40mm bb=0r/min cc=1.5+-0.3mm

----------

a=22deg+-5deg b=41deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of timer's threaded hole at the No. 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=10deg

----------

a=(40deg)

----------

aa=10deg

----------

a=(40deg)

Information:

This is a 4.0-hour job

PARTS DISPOSITION

Handle the parts in accordance with your Warranty Bulletin on warranty parts handling.

Rework Procedure

Step 1: Ensure CEM has cooled prior to beginning work. Use a temp gun to ensure that the temperature of the injector is at a safe to handle temperature.

Image1.1.1

Step 2: Once the CEM is at a safe temperature to begin work, remove air and DEF line connections at the injector. Ensure all permits and appropriate scaffolding or man-lift type equipment with sufficient personnel are on site or available if needed. This procedure may require two individuals with all the required PPE to handle the weight and distance to reach for work to be performed.

Image1.2.1

Step 3: Remove eight bolts and remove injector assembly from the CEM. This step may require two individuals due to the weight of the injector.

Step 4: Remove the nozzle group from the injector.

Image1.4.1

Step 5: Apply Loctite (nickel free) dry film anti-seize on the threads of the 352-0865 nozzle group. Ensure that only the threads receive anti-seize as the nozzle could suffer plugging if anti-seize contaminates the tip. Install the nozzle group with a new gasket onto the injector group and tighten to 30 +/- 2 Nm.

Image1.5.1

Step 6: Reinstall the injector with new nozzle and new gasket into the CEM matching alignment notches and tighten the eight (8) mounting bolts to standard torque. This step may require two individuals due to the weight of the injector.

Image1.6.1

Step 7: Using a stamping die set, the old injector part number must be removed. This can be accomplished using the X stamp and stamping out all of the part numbers (XXXXXXXX) or a grinder can be used to permanently remove the part number.

Step 8: Using the stamping die set, stamp part number 549-2925 on the flange of the injector as shown in Image 1.6.1.

Step 9: Perform ECM replacement and save all parameters in Product Status Report. Install software part number 590-2884 or latest available on SIS Web into the dosing cabinet ECM.

Step 10: Once flash is complete, perform a complete power cycle of the package and power up: Engine, Control Panel and Dosing system simultaneously. Verify flash and settings are correct in Aftertreatment configuration.

Please note that re-commissioning of the SCR system is not required after the software update if the system has already been commissioned.

Step 11: If Air Assist pressure is low or high then Air Manifold Regulator Adjust Procedure may be required:

Tools Required to Adjust Regulator in Dosing Cabinet:

? Laptop with CatET

? CA3

? 4mm Allen Key

? 8mm Socket to remove access panels

? 0-150 psi gauge with 9/16-18 JIC tees to measure pressure at dosing cabinet inlet

Air Regulator Adjustment Procedure

? Connect CatET to cabinet

? Record air pressure supply before air manifold with a gauge

? Adjust air supply to dosing cabinet if not in spec

? Air Supply in spec. continue

? In ET Override screen, Monitor Air Assist Pressure

? In ET Override screen, Override Air Assist and DEF Return valves

? Monitor and Record Air Assist pressure: Target is 65psi with both valves Override to