Information injection-pump assembly

ZEXEL

106671-6121

1066716121

ISUZU

1156031151

1156031151

Rating:

Cross reference number

ZEXEL

106671-6121

1066716121

ISUZU

1156031151

1156031151

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8250

Bosch type code

1 688 901 101

Nozzle

105780-0120

Bosch type code

1 688 901 990

Nozzle holder

105780-2190

Opening pressure

MPa

20.7

Opening pressure

kgf/cm2

211

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

134424-4320

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

255

255

255

Tester oil delivery pressure

kgf/cm2

2.6

2.6

2.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

5.2

5.17

5.23

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.75 60.25

Cal 1-5 deg. 60 59.75 60.25

Difference between angles 2

Cal 1-3 deg. 120 119.75 120.25

Cal 1-3 deg. 120 119.75 120.25

Difference between angles 3

Cal 1-6 deg. 180 179.75 180.25

Cal 1-6 deg. 180 179.75 180.25

Difference between angles 4

Cyl.1-2 deg. 240 239.75 240.25

Cyl.1-2 deg. 240 239.75 240.25

Difference between angles 5

Cal 1-4 deg. 300 299.75 300.25

Cal 1-4 deg. 300 299.75 300.25

Injection quantity adjustment

Adjusting point

-

Rack position

11.9

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

116.5

114.5

118.5

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

Z

Rack position

6.5+-0.5

Pump speed

r/min

440

440

440

Average injection quantity

mm3/st.

15

11.8

18.2

Max. variation between cylinders

%

0

-13

13

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(11.9)

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

116.5

114.5

118.5

Basic

*

Fixing the lever

*

Boost pressure

kPa

36

36

Boost pressure

mmHg

270

270

Injection quantity adjustment_04

Adjusting point

B

Rack position

(R1-0.05

)

Pump speed

r/min

650

650

650

Average injection quantity

mm3/st.

133.5

127.5

139.5

Fixing the lever

*

Boost pressure

kPa

36

36

Boost pressure

mmHg

270

270

Boost compensator adjustment

Pump speed

r/min

430

430

430

Rack position

R2-1.7

Boost pressure

kPa

7.3

6

8.6

Boost pressure

mmHg

55

45

65

Boost compensator adjustment_02

Pump speed

r/min

430

430

430

Rack position

R2(R1-0.

6)

Boost pressure

kPa

22.7

22.7

22.7

Boost pressure

mmHg

170

170

170

Timer adjustment

Pump speed

r/min

850--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

800

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

950

Advance angle

deg.

2

1.5

2.5

Remarks

Finish

Finish

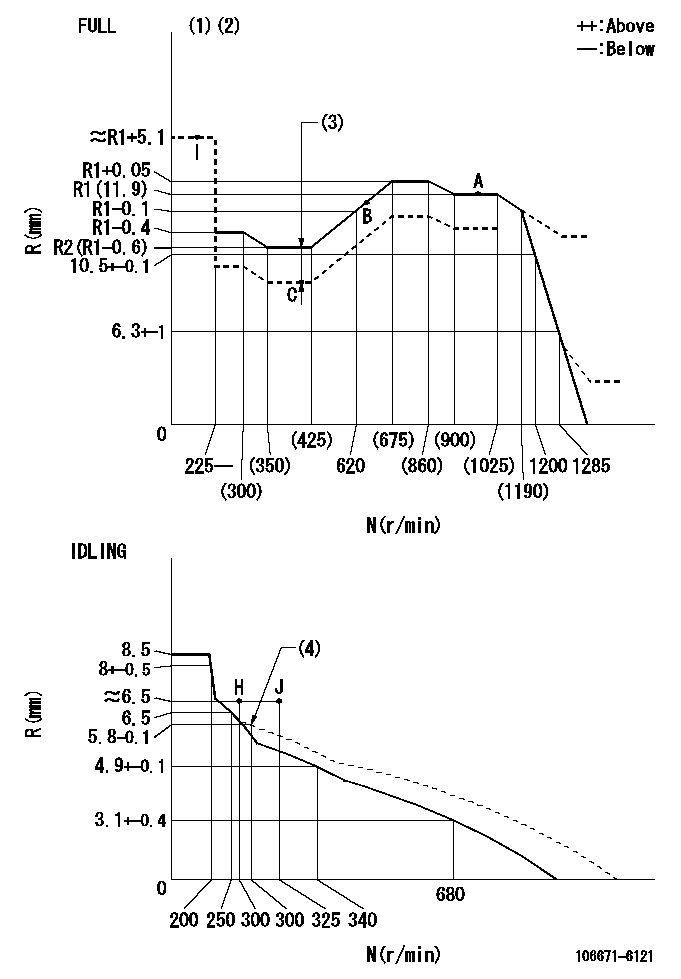

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)Tolerance for racks not indicated: +-0.05mm.

(3)Boost compensator stroke: BCL

(4)Damper spring setting

----------

T1=AE57 BCL=1.7+-0.1mm

----------

----------

T1=AE57 BCL=1.7+-0.1mm

----------

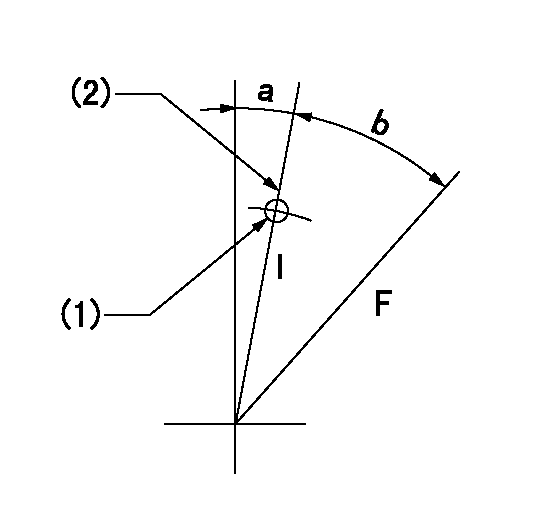

Speed control lever angle

F:Full speed

I:Idle

(1)Use the pin at R = aa

(2)Stopper bolt set position 'H'

----------

aa=32mm

----------

a=4deg+-5deg b=30.5deg+-3deg

----------

aa=32mm

----------

a=4deg+-5deg b=30.5deg+-3deg

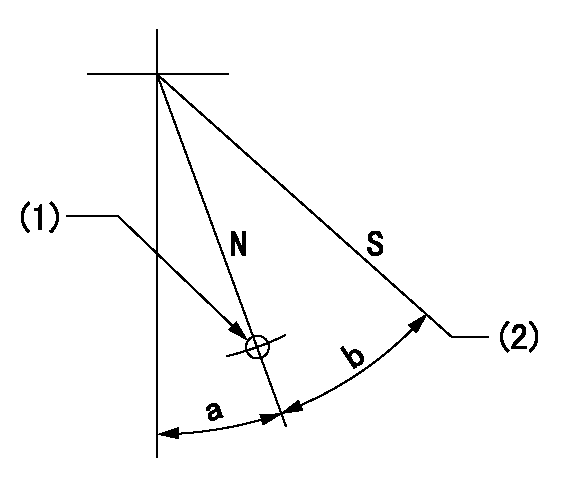

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Use the pin at R = aa

(2)Set the stopper bolt so that speed = bb and rack position = cc. (Confirm non-injection.)

----------

aa=40mm bb=0r/min cc=1+-0.3mm

----------

a=18deg+-5deg b=44deg+-5deg

----------

aa=40mm bb=0r/min cc=1+-0.3mm

----------

a=18deg+-5deg b=44deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of timer's threaded hole at the No. 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=14deg

----------

a=(100deg)

----------

aa=14deg

----------

a=(100deg)

Information:

Tooling and Equipment

The tools shown in Chart F, Tooling for Finding Top Center (TC) Position, are required to complete the procedure.

Table 8

Chart F

Tooling For Finding Top Center (TC) Position

Part No Description Qty Item (1)

8T-4177 Bolt, Spring Compressor 1 7

( 1 ) Refer to the nomenclature chart at the beginning of this manual for item identification.Procedure

Illustration 39 g03425683

Timing Bolt Location (35) 8T-4177 Timing Bolt (36) Timing Hole (37) Flywheel HousingNote: Depending on engine application, timing hole (36) is located at either the left front face or the right front face of the flywheel housing.

Remove plug from the timing hole (36) on the front of the flywheel housing.

Rotate the engine with four large bolts on the front of the crankshaft. Do not use the eight small bolts on the front of the crankshaft pulley as this could cause damage to the engine.

Put 8T-4177 Bolt (35) in hole. Turn the engine flywheel counterclockwise until the timing bolt engages with the threaded hole in the flywheel.Note: If the flywheel is turned beyond the point the timing bolt engages in the threaded hole, the flywheel must be turned back at least 30 degrees clockwise. Again, turn the flywheel counterclockwise until the timing bolt engages with the threaded hole. This procedure makes sure that the play is removed from the gears when number 1 piston is put on TC.

Remove the cylinder head valve cover.

Illustration 40 g03425694

Valve Cover Removed

The intake and the exhaust valves for the number 1 cylinder are fully closed if number 1 piston is on the compression stroke and the rocker arms can be moved by hand. If the rocker arms cannot be moved and the valves are slightly open, the number 1 piston is on the exhaust strike. Refer to Chart E, Crankshaft Positions for Fuel Timing Settings, to determine which cylinders can be checked/adjusted (determined by stroke position of crankshaft when timing bolt is installed).Note: When the actual stroke position is identified, and the other stroke position is desired, it is necessary to remove the timing bolt from the flywheel. Turn the flywheel counterclockwise 360 degrees, and reinstall the timing bolt.

After TC position for a particular stroke is obtained and adjustments are made, remove the timing bolt and turn the flywheel counterclockwise 360 degrees. This will put number 1 piston at TC position on the other stroke. Install timing bolt in the flywheel and complete adjustments for remaining cylinders.Removal and Installation of Unit Fuel Injectors

Table 9

Chart G

Injector Removal and Installation Tools

Part No Description Qty Item (1)

5P-0302 Injector Removal Bar 1 16

194-3542 Hex Socket Bit Driver, 5 mm 1 18

( 1 ) Refer to nomenclature chart, at the beginning of this manual for item identification.

Illustration 41 g03425701

Unit Fuel Injector (48) Bolt (49) O-RingsNote: Not all injectors use a bottom O-ring.Removal

Remove injector hold down bolt (48) .

Do not pry on the injector hold down bracket.

The tools shown in Chart F, Tooling for Finding Top Center (TC) Position, are required to complete the procedure.

Table 8

Chart F

Tooling For Finding Top Center (TC) Position

Part No Description Qty Item (1)

8T-4177 Bolt, Spring Compressor 1 7

( 1 ) Refer to the nomenclature chart at the beginning of this manual for item identification.Procedure

Illustration 39 g03425683

Timing Bolt Location (35) 8T-4177 Timing Bolt (36) Timing Hole (37) Flywheel HousingNote: Depending on engine application, timing hole (36) is located at either the left front face or the right front face of the flywheel housing.

Remove plug from the timing hole (36) on the front of the flywheel housing.

Rotate the engine with four large bolts on the front of the crankshaft. Do not use the eight small bolts on the front of the crankshaft pulley as this could cause damage to the engine.

Put 8T-4177 Bolt (35) in hole. Turn the engine flywheel counterclockwise until the timing bolt engages with the threaded hole in the flywheel.Note: If the flywheel is turned beyond the point the timing bolt engages in the threaded hole, the flywheel must be turned back at least 30 degrees clockwise. Again, turn the flywheel counterclockwise until the timing bolt engages with the threaded hole. This procedure makes sure that the play is removed from the gears when number 1 piston is put on TC.

Remove the cylinder head valve cover.

Illustration 40 g03425694

Valve Cover Removed

The intake and the exhaust valves for the number 1 cylinder are fully closed if number 1 piston is on the compression stroke and the rocker arms can be moved by hand. If the rocker arms cannot be moved and the valves are slightly open, the number 1 piston is on the exhaust strike. Refer to Chart E, Crankshaft Positions for Fuel Timing Settings, to determine which cylinders can be checked/adjusted (determined by stroke position of crankshaft when timing bolt is installed).Note: When the actual stroke position is identified, and the other stroke position is desired, it is necessary to remove the timing bolt from the flywheel. Turn the flywheel counterclockwise 360 degrees, and reinstall the timing bolt.

After TC position for a particular stroke is obtained and adjustments are made, remove the timing bolt and turn the flywheel counterclockwise 360 degrees. This will put number 1 piston at TC position on the other stroke. Install timing bolt in the flywheel and complete adjustments for remaining cylinders.Removal and Installation of Unit Fuel Injectors

Table 9

Chart G

Injector Removal and Installation Tools

Part No Description Qty Item (1)

5P-0302 Injector Removal Bar 1 16

194-3542 Hex Socket Bit Driver, 5 mm 1 18

( 1 ) Refer to nomenclature chart, at the beginning of this manual for item identification.

Illustration 41 g03425701

Unit Fuel Injector (48) Bolt (49) O-RingsNote: Not all injectors use a bottom O-ring.Removal

Remove injector hold down bolt (48) .

Do not pry on the injector hold down bracket.