Information injection-pump assembly

ZEXEL

106671-6070

1066716070

ISUZU

1156029751

1156029751

Rating:

Service parts 106671-6070 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

1-15300-289-2

12.

Open Pre:MPa(Kqf/cm2)

19.6{200}

15.

NOZZLE SET

Include in #1:

106671-6070

as INJECTION-PUMP ASSEMBLY

Cross reference number

ZEXEL

106671-6070

1066716070

ISUZU

1156029751

1156029751

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

134424-1920

Overflow valve opening pressure

kPa

127

107

147

Overflow valve opening pressure

kgf/cm2

1.3

1.1

1.5

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3.7

3.67

3.73

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.75 60.25

Cal 1-5 deg. 60 59.75 60.25

Difference between angles 2

Cal 1-3 deg. 120 119.75 120.25

Cal 1-3 deg. 120 119.75 120.25

Difference between angles 3

Cal 1-6 deg. 180 179.75 180.25

Cal 1-6 deg. 180 179.75 180.25

Difference between angles 4

Cyl.1-2 deg. 240 239.75 240.25

Cyl.1-2 deg. 240 239.75 240.25

Difference between angles 5

Cal 1-4 deg. 300 299.75 300.25

Cal 1-4 deg. 300 299.75 300.25

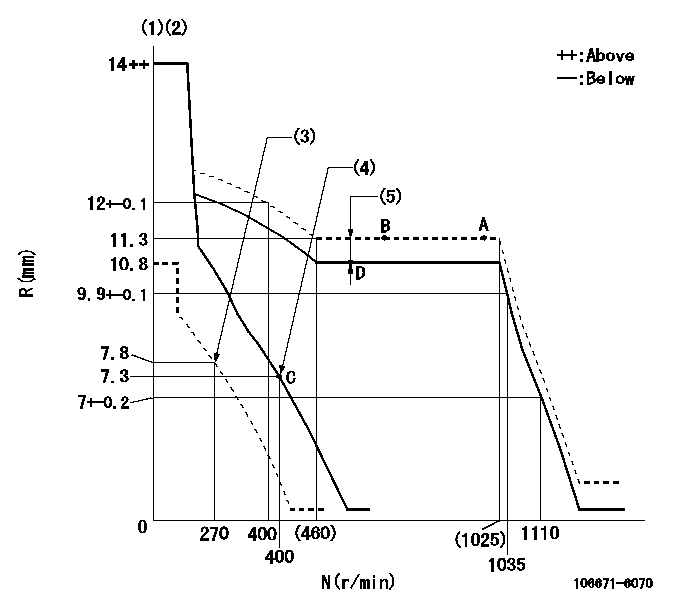

Injection quantity adjustment

Adjusting point

A

Rack position

11.3

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

135

133

137

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the lever

*

Boost pressure

kPa

73.3

73.3

Boost pressure

mmHg

550

550

Injection quantity adjustment_02

Adjusting point

-

Rack position

8.4+-0.5

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

14.5

11.3

17.7

Max. variation between cylinders

%

0

-13

13

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Boost compensator adjustment

Pump speed

r/min

500

500

500

Rack position

R1-0.9

Boost pressure

kPa

32

29.3

34.7

Boost pressure

mmHg

240

220

260

Boost compensator adjustment_02

Pump speed

r/min

500

500

500

Rack position

R1-0.65

Boost pressure

kPa

40

38.7

41.3

Boost pressure

mmHg

300

290

310

Boost compensator adjustment_03

Pump speed

r/min

500

500

500

Rack position

R1(11.3)

Boost pressure

kPa

60

60

60

Boost pressure

mmHg

450

450

450

Timer adjustment

Pump speed

r/min

1000++

Advance angle

deg.

0

0

0

Remarks

Do not advance until starting N = 1000.

Do not advance until starting N = 1000.

Timer adjustment_02

Pump speed

r/min

1100

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

-

Advance angle

deg.

1

1

1

Remarks

Measure the actual speed, stop

Measure the actual speed, stop

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)Set idle sub-spring

(4)Main spring setting

(5)Boost compensator stroke: BCL

----------

K=14 BCL=0.9+-0.1mm

----------

----------

K=14 BCL=0.9+-0.1mm

----------

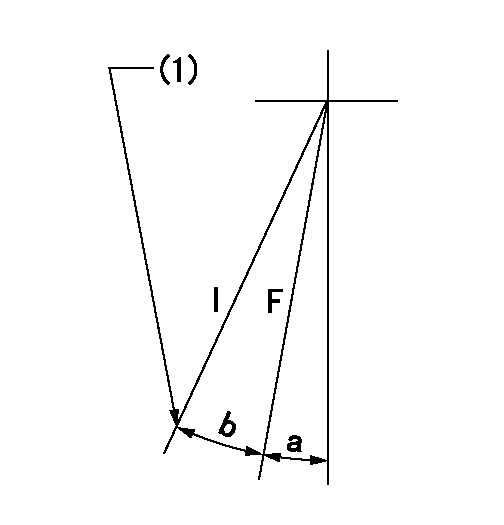

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=6deg+-5deg b=17deg+-5deg

----------

----------

a=6deg+-5deg b=17deg+-5deg

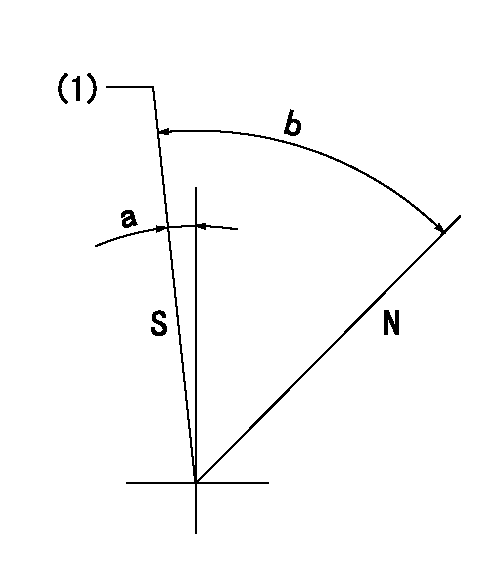

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Rack position = aa, speed = bb (stamp at delivery)

----------

aa=1-0.5mm bb=0r/min

----------

a=15deg+-5deg b=70deg+-5deg

----------

aa=1-0.5mm bb=0r/min

----------

a=15deg+-5deg b=70deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of timer's threaded hole at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=14deg

----------

a=(50deg)

----------

aa=14deg

----------

a=(50deg)

Information:

Image1.2.1

Image1.2.2

Image1.2.3

3 - Using long straps and a crane, tilt the DOC on end so the outlet with the perforated plate end is facing up. With the DOC rotated on end, locate and center the drilling template and use C-Clamps to clamp the template in place so it does not shift.

With the DOC in this position ensure that all of the inside insulation pieces and the perforated plate are still in the correct position and in place.

Reference Image 1.3.1 and 1.3.2

Image1.3.1

Image1.3.2

4 - Position a mag base drill on the drilling template. While holding the inside perforated plate in position with a piece of 2" x 4" x 8' piece of lumber or other suitable size, drill the (4) 1.25" (31.75 mm) holes using a carbide tip cutter bit. Drill through the DOC end plate and insulation making sure the carbide tip cutter bit does NOT go through the perforated plate on the inside.

Note: A Hougen magnetic base drill works best for the drilling process and use a Hougen Copperhead Carbide Tip Annular Cutter bit. Hougen p/n 18240

Once the holes are drilled through clean out the drilled material.

Change out the carbide tip hole saw bit with a 3/8" drill bit. Ensure that the mag base drill stays in the same position so the 3/8" bit is drilling in the center of the 1.25" hole.

Note: The spacer can also be inserted in the 1.25" hole to use as a template to drill the 3/8" hole.

Drill a 3/8" hole through the inside perforated plate being careful not to drill too deep. From the outside end plate, the minimum drilling depth is 45 mm and the maximum drilling depth is 150 mm.

Note: This is a two person process with one person holding the inside perforated plate in place while the other person is drilling the holes. Additionally, the drilling through DOC should be done slowly as to not bend or drill through the perforated plate.

Reference Image 1.4.1 and 1.4.2

Image1.4.1

Image1.4.2

5 - Install the 1.25" spacer and slotted washer (Pacman washer) into each of the (4) drilled holes. The slotted washer will have to be angled in with needle nosed pliers and then moved in place in order to get it in the correct location. As an alternative to using needle nosed pliers, a thin wire tie can be tied around the slotted washer and lowered into the hole out of the way until it is re-positioned on top of the spacer.

Reference Images 1.5.1 and 1.5.2

Image1.5.1

Image1.5.2

6 - Once the spacer and slotted washer (Pacman washer) are installed in the DOC, install the 1.25" washer on top of the slotted washer. The 1.25" washer needs to be coated on both sides with Loctite 2620 sealant prior to installation.

From the outside of the DOC, install (2) each of the 3/8" bolt, small bolt washer, 2" washers and Graphite gasket through the holes in the slotted washers and spacers. On the inside of the DOC install an L Angle piece onto the lower 3/8" bolt threads and then