Information injection-pump assembly

ZEXEL

106671-6050

1066716050

ISUZU

1156030370

1156030370

Rating:

Service parts 106671-6050 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

1-15300-337-0

12.

Open Pre:MPa(Kqf/cm2)

22.1{225}

15.

NOZZLE SET

Include in #1:

106671-6050

as INJECTION-PUMP ASSEMBLY

Cross reference number

ZEXEL

106671-6050

1066716050

ISUZU

1156030370

1156030370

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

134424-3920

Overflow valve opening pressure

kPa

127

107

147

Overflow valve opening pressure

kgf/cm2

1.3

1.1

1.5

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

4

3.97

4.03

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.75 60.25

Cal 1-5 deg. 60 59.75 60.25

Difference between angles 2

Cal 1-3 deg. 120 119.75 120.25

Cal 1-3 deg. 120 119.75 120.25

Difference between angles 3

Cal 1-6 deg. 180 179.75 180.25

Cal 1-6 deg. 180 179.75 180.25

Difference between angles 4

Cyl.1-2 deg. 240 239.75 240.25

Cyl.1-2 deg. 240 239.75 240.25

Difference between angles 5

Cal 1-4 deg. 300 299.75 300.25

Cal 1-4 deg. 300 299.75 300.25

Injection quantity adjustment

Adjusting point

A

Rack position

12

Pump speed

r/min

1400

1400

1400

Average injection quantity

mm3/st.

163.5

161.5

165.5

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the lever

*

Boost pressure

kPa

153

153

Boost pressure

mmHg

1150

1150

Injection quantity adjustment_02

Adjusting point

B

Rack position

6.3+-0.5

Pump speed

r/min

250

250

250

Average injection quantity

mm3/st.

15

11.8

18.2

Max. variation between cylinders

%

0

-13

13

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Boost compensator adjustment

Pump speed

r/min

600

600

600

Rack position

R1-2.1

Boost pressure

kPa

33.3

30.6

36

Boost pressure

mmHg

250

230

270

Boost compensator adjustment_02

Pump speed

r/min

600

600

600

Rack position

R1(12)

Boost pressure

kPa

140

140

140

Boost pressure

mmHg

1050

1050

1050

Timer adjustment

Pump speed

r/min

1400++

Advance angle

deg.

0

0

0

Remarks

Do not advance until starting N = 1400.

Do not advance until starting N = 1400.

Timer adjustment_02

Pump speed

r/min

-

Advance angle

deg.

0.7

0.7

0.7

Remarks

Measure the actual speed, stop

Measure the actual speed, stop

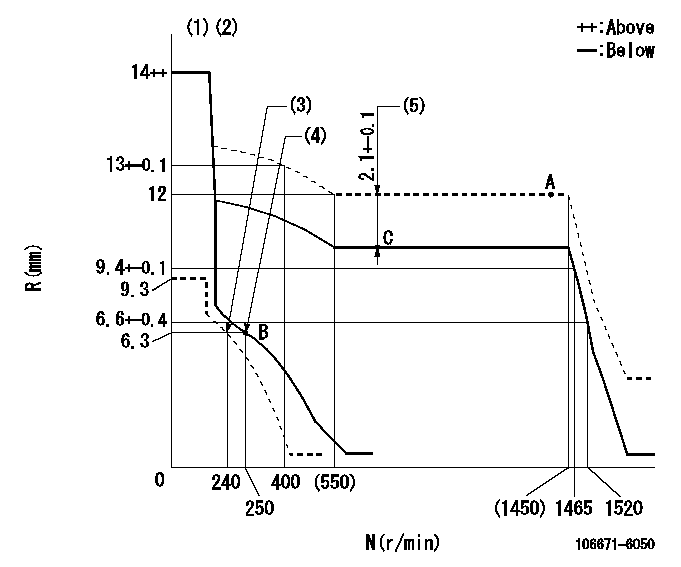

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)Set idle sub-spring

(4)Main spring setting

(5)Boost compensator stroke

----------

K=7

----------

----------

K=7

----------

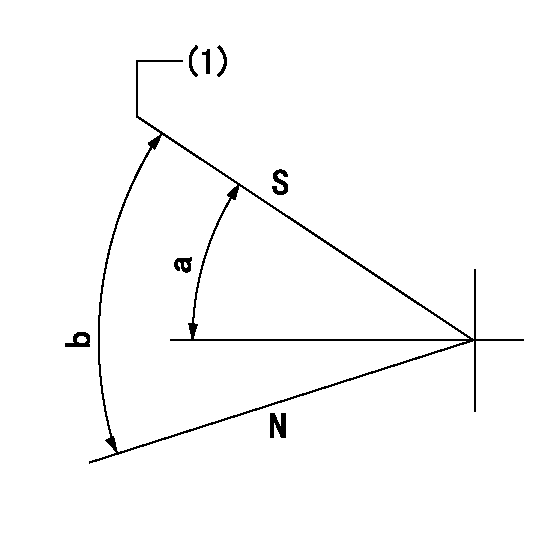

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=15deg+-5deg b=31deg+-5deg

----------

----------

a=15deg+-5deg b=31deg+-5deg

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Pump speed aa and rack position bb (to be sealed at delivery)

----------

aa=1-0.5mm bb=0r/min

----------

a=25.5deg+-5deg b=70deg+-5deg

----------

aa=1-0.5mm bb=0r/min

----------

a=25.5deg+-5deg b=70deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of timer's threaded hole at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(50deg)

----------

----------

a=(50deg)

Information:

Model Identification Number

AFTERTREAT-SCR ES700101, 105-170, 231-259, 266-273

PARTS NEEDED

Qty

Part Number Description

1 4487104 DISC-SUPPORT

In order to allow equitable parts availability to all participating dealers, please limit your initial parts order to not exceed 32% of dealership population. This is an initial order recommendation only, and the ultimate responsibility for ordering the total number of parts needed to satisfy the program lies with the dealer.

ACTION REQUIRED

Prior to Disassembly:

Remove/Turn off all power to the dosing cabinet.

Lock Out and Tag Out the master disconnect.

Follow all mandated safety rules.

Please refer to the attached Rework Procedure.

SERVICE CLAIM ALLOWANCES

Product smu/age whichever comes first Caterpillar Dealer Suggested Customer Suggested

Parts % Labor Hrs% Parts % Labor Hrs% Parts % Labor Hrs%

0-8000 hrs,

0-24 mo 100.0% 100.0% 0.0% 0.0% 0.0% 0.0%

This is a 2.0-hour job

PARTS DISPOSITION

Handle the parts in accordance with your Warranty Bulletin on warranty parts handling.

Rework Procedure

Early production dosing cabinets under went several changes with the Diesel Exhaust Fluid Back Pressure Valves that were installed at the factory. (A) Plastic Housing, (B) Stainless Steel Housing, and (C) Stainless Steel Body with Plastic Cap. Refer Image 1.1.1.

Identify the Diesel Exhaust Fluid Back Pressure Valve in the dosing cabinet, and proceed to the appropriate rework procedure below.

Remove the Diesel Exhaust Fluid Back Pressure Valve from dosing cabinet. Refer to Image 1.1.2.

Disassemble and replace the internal support disc. Refer to Image 1.1.3.

Reassemble valve and tighten the assembly screws 5 Nm ( 43 in lb ). Reinstall valve into dosing cabinet.

Once Diesel Exhaust Fluid Back Pressure Valve has been reinstalled, it is necessary

to set the back pressure valve at ~40 psi. This is an important adjustment. If the back pressure valve is set too low it will not be able to seal against the DEF head pressure, and can flood the reactor. If the valve is set two high, it can stop all flow of DEF, and will force DEF out the pump pressure release valve, possibly damaging the pump.

Procedure to Set Back Pressure Valve

Plastic Housing (A) or Stainless Steel Housing (B)

The field method of setting the valve is to back off the adjustment screw until the spring pressure is released, tighten the screw until contact is made with the spring, then tighten the screw two complete revolutions. The adjustment screw gives ~20 psi per revolution of the screw, so two turns sets it at about 40 psi.

Note: Special care should be taken when determining when the screw makes contact with the spring. Occasionally the screw can be tight, making it hard to determine when the screw makes contact with the spring. Lubricating the screw can help.

Stainless Steel Body with Plastic Cap (C)

The valve may be marked as BPM025SV50P. Refer to Image 1.1.4. If the spring has 9 coils (A), unscrew