Information injection-pump assembly

ZEXEL

106671-6040

1066716040

ISUZU

1156030510

1156030510

Rating:

Cross reference number

ZEXEL

106671-6040

1066716040

ISUZU

1156030510

1156030510

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

134424-1920

Overflow valve opening pressure

kPa

127

107

147

Overflow valve opening pressure

kgf/cm2

1.3

1.1

1.5

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

4.5

4.47

4.53

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.75 60.25

Cal 1-5 deg. 60 59.75 60.25

Difference between angles 2

Cal 1-3 deg. 120 119.75 120.25

Cal 1-3 deg. 120 119.75 120.25

Difference between angles 3

Cal 1-6 deg. 180 179.75 180.25

Cal 1-6 deg. 180 179.75 180.25

Difference between angles 4

Cyl.1-2 deg. 240 239.75 240.25

Cyl.1-2 deg. 240 239.75 240.25

Difference between angles 5

Cal 1-4 deg. 300 299.75 300.25

Cal 1-4 deg. 300 299.75 300.25

Injection quantity adjustment

Adjusting point

-

Rack position

11.5

Pump speed

r/min

800

800

800

Average injection quantity

mm3/st.

146.5

144.5

148.5

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

H

Rack position

6.5+-0.5

Pump speed

r/min

240

240

240

Average injection quantity

mm3/st.

11.5

8.3

14.7

Max. variation between cylinders

%

0

-13

13

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(11.5)

Pump speed

r/min

800

800

800

Average injection quantity

mm3/st.

146.5

144.5

148.5

Basic

*

Fixing the lever

*

Boost pressure

kPa

26.7

26.7

Boost pressure

mmHg

200

200

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

140.5

134.5

146.5

Fixing the lever

*

Boost pressure

kPa

26.7

26.7

Boost pressure

mmHg

200

200

Boost compensator adjustment

Pump speed

r/min

500

500

500

Rack position

R2-1

Boost pressure

kPa

8

6.7

9.3

Boost pressure

mmHg

60

50

70

Boost compensator adjustment_02

Pump speed

r/min

500

500

500

Rack position

R2(R1-1.

4)

Boost pressure

kPa

13.3

13.3

13.3

Boost pressure

mmHg

100

100

100

Timer adjustment

Pump speed

r/min

850--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

800

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

875

Advance angle

deg.

1.5

1

2

Remarks

Finish

Finish

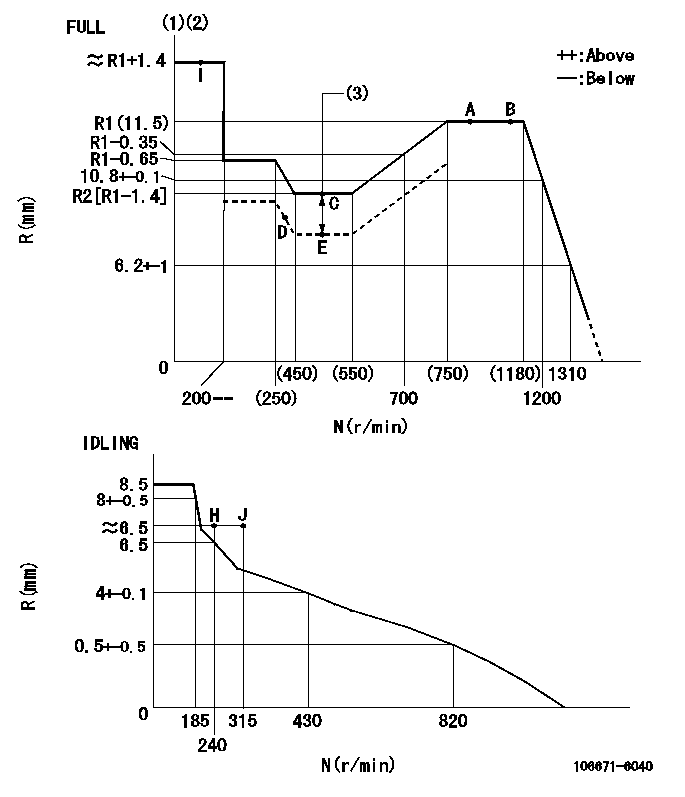

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)Tolerance for racks not indicated: +-0.05mm.

(3)Boost compensator stroke: BCL

----------

T1=AD02 BCL=1+-0.1mm

----------

----------

T1=AD02 BCL=1+-0.1mm

----------

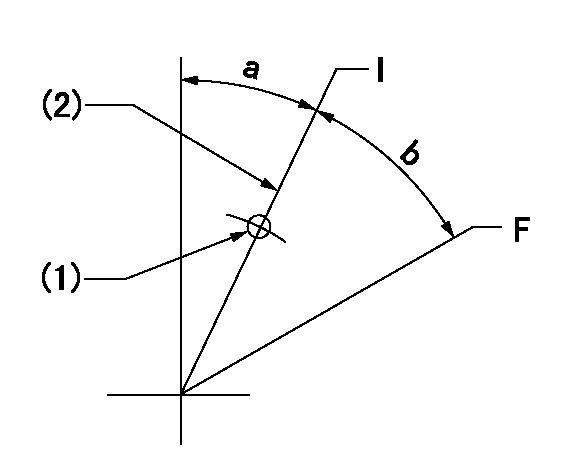

Speed control lever angle

F:Full speed

I:Idle

(1)Use the pin at R = aa

(2)Stopper bolt set position 'H'

----------

aa=35mm

----------

a=24.5deg+-5deg b=(34deg)+-3deg

----------

aa=35mm

----------

a=24.5deg+-5deg b=(34deg)+-3deg

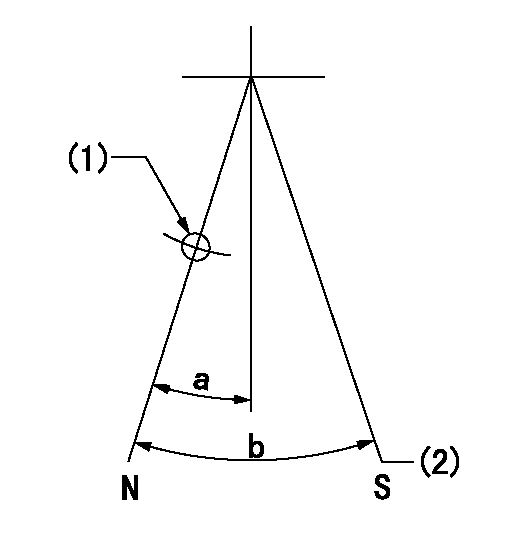

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Use the pin at R = aa

(2)Set the stopper bolt so that speed = bb and rack position = cc. (Confirm non-injection.)

----------

aa=40mm bb=0r/min cc=1.5+-0.3mm

----------

a=22deg+-5deg b=41deg+-5deg

----------

aa=40mm bb=0r/min cc=1.5+-0.3mm

----------

a=22deg+-5deg b=41deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of timer's threaded hole at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=10deg

----------

a=(50deg)

----------

aa=10deg

----------

a=(50deg)

Information:

5N5930 Fuel Injection Lines Group

(1) Remove former fuel injection lines (1) from each fuel injection pump to the adapters in the base of the valve mechanism cover. Remove the cover from the base. Remove the through-the-base adapter for each set of fuel lines. Put an 8M4437 Seal on each 1W6777 Adapter (2) and install the adapters in each bore where the adapters were removed. Use engine oil as a lubricant on the seals. Fasten the adapters to the cover base with the former nuts and two 5N5365 Locks on each. Connect former fuel lines (3) to adapters (2) and to the injector nozzles. (2) Install 2W2496 Bracket (4) and 2W2495 Bracket (5) where the former brackets were removed. Put a 5P9267 Seal on each injector pump and put a 2W2500 Washer (6) and 6V6579 Seal (7) on each adapter (2). Loosely install the fuel injection line assemblies that follow: 1W6318 (8), 1W6316 (9), 1W6313 (10), 1W6317 (11), 1W6315 (12), 1W6312 (13), 1W6314 (14) and 1W6311 (15). Tighten fuel injection line nuts (16) on each fuel line to 41 7 N m (30 5 lb.ft.) before cover nuts (17) are tightened. If the fuel lines have metal tags for part number identification, remove the tags before installation. Fasten tubes (8), (9), (12) and (15) together on the left side with four 2W2492 Clamps (18), 2W2493 Clamps and 310216 Bolts. Fasten the fuel lines to brackets (4) and (5) with 2W2492 Clamps (19), 2W2493 Clamps, 2W2494 Spacers, 1D4533 Bolts and 3B4504 Lockwashers. Fasten the fuel injection lines together on the right side with 2W2492 Clamps (20), 2W2493 Clamps and 310216 Bolts. Install four 2W2498 and 2W2499 Clamps on tubes (12) and (14) with 6V5370 Screws as shown.2W1788 Fuel Lines Drain Group

(1) Install a 9L8496 Tee (1) on each fuel line adapter (2). Install six 5N5940 Tube Assemblies (3) between tees (1) as shown. Install two 9L8492 Plugs (4). Install 2W3092 Tube Assembly (5), 2W3091 Tube Assembly (6) and 9L8557 Tee (7). Install 4M5317 Bushing (8) and 8B1931 Bushing (9) in 2N9768 Switch (10). Install 9L8496 Tee (11) in bushing (9). Fasten switch (10) to 2W3089 Bracket Assembly (12) with two S1616 Bolts, four 5P537 Washers and two 9S8750 Nuts. Fasten bracket (12) to the side of the engine with two S1594 Bolts, 5M2894 Washers and 9S8752 Nuts. Connect 2W3935 Tube Assembly (13) to tees (7) and (11). Install a 9L8492 Plug in the other side of tee (11). Install 5K9243 Elbow (14) in bushing (8). Connect 5N7739 Tube Assembly (15) to elbow (14). Fasten tubes (13) and (15) to existing bolts with 2B2404 Clips (16).

(1) Remove former fuel injection lines (1) from each fuel injection pump to the adapters in the base of the valve mechanism cover. Remove the cover from the base. Remove the through-the-base adapter for each set of fuel lines. Put an 8M4437 Seal on each 1W6777 Adapter (2) and install the adapters in each bore where the adapters were removed. Use engine oil as a lubricant on the seals. Fasten the adapters to the cover base with the former nuts and two 5N5365 Locks on each. Connect former fuel lines (3) to adapters (2) and to the injector nozzles. (2) Install 2W2496 Bracket (4) and 2W2495 Bracket (5) where the former brackets were removed. Put a 5P9267 Seal on each injector pump and put a 2W2500 Washer (6) and 6V6579 Seal (7) on each adapter (2). Loosely install the fuel injection line assemblies that follow: 1W6318 (8), 1W6316 (9), 1W6313 (10), 1W6317 (11), 1W6315 (12), 1W6312 (13), 1W6314 (14) and 1W6311 (15). Tighten fuel injection line nuts (16) on each fuel line to 41 7 N m (30 5 lb.ft.) before cover nuts (17) are tightened. If the fuel lines have metal tags for part number identification, remove the tags before installation. Fasten tubes (8), (9), (12) and (15) together on the left side with four 2W2492 Clamps (18), 2W2493 Clamps and 310216 Bolts. Fasten the fuel lines to brackets (4) and (5) with 2W2492 Clamps (19), 2W2493 Clamps, 2W2494 Spacers, 1D4533 Bolts and 3B4504 Lockwashers. Fasten the fuel injection lines together on the right side with 2W2492 Clamps (20), 2W2493 Clamps and 310216 Bolts. Install four 2W2498 and 2W2499 Clamps on tubes (12) and (14) with 6V5370 Screws as shown.2W1788 Fuel Lines Drain Group

(1) Install a 9L8496 Tee (1) on each fuel line adapter (2). Install six 5N5940 Tube Assemblies (3) between tees (1) as shown. Install two 9L8492 Plugs (4). Install 2W3092 Tube Assembly (5), 2W3091 Tube Assembly (6) and 9L8557 Tee (7). Install 4M5317 Bushing (8) and 8B1931 Bushing (9) in 2N9768 Switch (10). Install 9L8496 Tee (11) in bushing (9). Fasten switch (10) to 2W3089 Bracket Assembly (12) with two S1616 Bolts, four 5P537 Washers and two 9S8750 Nuts. Fasten bracket (12) to the side of the engine with two S1594 Bolts, 5M2894 Washers and 9S8752 Nuts. Connect 2W3935 Tube Assembly (13) to tees (7) and (11). Install a 9L8492 Plug in the other side of tee (11). Install 5K9243 Elbow (14) in bushing (8). Connect 5N7739 Tube Assembly (15) to elbow (14). Fasten tubes (13) and (15) to existing bolts with 2B2404 Clips (16).