Information injection-pump assembly

BOSCH

F 019 Z10 123

f019z10123

ZEXEL

106671-6026

1066716026

ISUZU

1156030686

1156030686

Rating:

Service parts 106671-6026 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

1-15300-356-2

12.

Open Pre:MPa(Kqf/cm2)

19.6{200}

15.

NOZZLE SET

Include in #1:

106671-6026

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

F 019 Z10 123

f019z10123

ZEXEL

106671-6026

1066716026

ISUZU

1156030686

1156030686

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8250

Bosch type code

1 688 901 101

Nozzle

105780-0120

Bosch type code

1 688 901 990

Nozzle holder

105780-2190

Opening pressure

MPa

20.7

Opening pressure

kgf/cm2

211

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

134424-4320

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

255

255

255

Tester oil delivery pressure

kgf/cm2

2.6

2.6

2.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

5.2

5.17

5.23

Rack position

Point A R=A

Point A R=A

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.75 60.25

Cal 1-5 deg. 60 59.75 60.25

Difference between angles 2

Cal 1-3 deg. 120 119.75 120.25

Cal 1-3 deg. 120 119.75 120.25

Difference between angles 3

Cal 1-6 deg. 180 179.75 180.25

Cal 1-6 deg. 180 179.75 180.25

Difference between angles 4

Cyl.1-2 deg. 240 239.75 240.25

Cyl.1-2 deg. 240 239.75 240.25

Difference between angles 5

Cal 1-4 deg. 300 299.75 300.25

Cal 1-4 deg. 300 299.75 300.25

Injection quantity adjustment

Adjusting point

-

Rack position

12.1

Pump speed

r/min

650

650

650

Average injection quantity

mm3/st.

139

137

141

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

Z

Rack position

6.5+-0.5

Pump speed

r/min

420

420

420

Average injection quantity

mm3/st.

15

11.8

18.2

Max. variation between cylinders

%

0

-13

13

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(12.1)

Pump speed

r/min

650

650

650

Average injection quantity

mm3/st.

139

137

141

Basic

*

Fixing the lever

*

Boost pressure

kPa

66.7

66.7

Boost pressure

mmHg

500

500

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1+0.4

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

125.5

119.5

131.5

Fixing the lever

*

Boost pressure

kPa

66.7

66.7

Boost pressure

mmHg

500

500

Boost compensator adjustment

Pump speed

r/min

450

450

450

Rack position

R2-2.85

Boost pressure

kPa

24

22.7

25.3

Boost pressure

mmHg

180

170

190

Boost compensator adjustment_02

Pump speed

r/min

450

450

450

Rack position

R2[R1-0.

65]

Boost pressure

kPa

53.3

53.3

53.3

Boost pressure

mmHg

400

400

400

Timer adjustment

Pump speed

r/min

850--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

800

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

950

Advance angle

deg.

2

1.5

2.5

Remarks

Finish

Finish

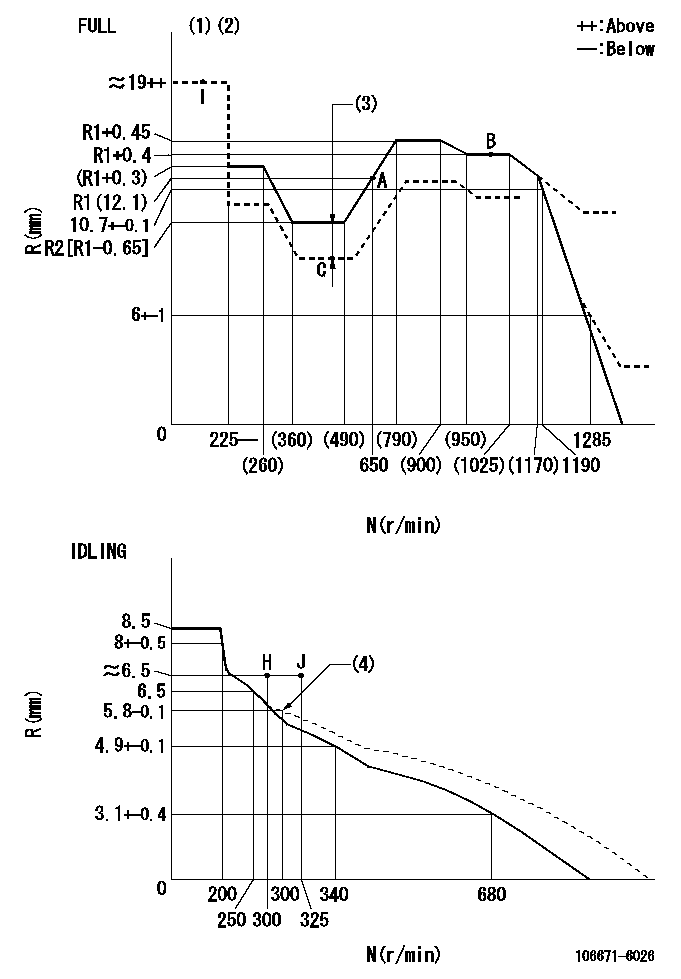

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)Tolerance for racks not indicated: +-0.05mm.

(3)Boost compensator stroke: BCL

(4)Damper spring setting

----------

T1=AD86 BCL=2.85+-0.1mm

----------

----------

T1=AD86 BCL=2.85+-0.1mm

----------

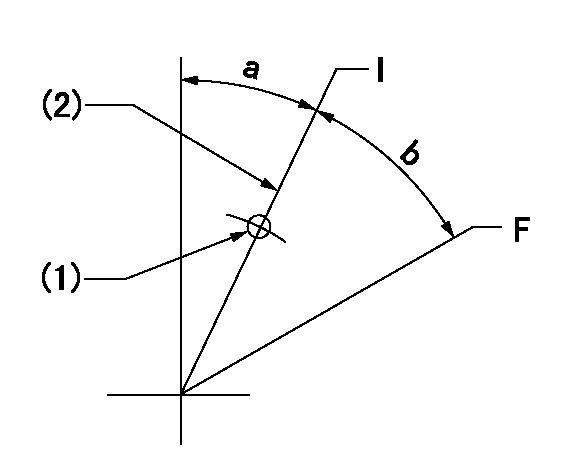

Speed control lever angle

F:Full speed

I:Idle

(1)Use the pin at R = aa

(2)Stopper bolt setting

----------

aa=32mm

----------

a=4deg+-5deg b=30.5deg+-3deg

----------

aa=32mm

----------

a=4deg+-5deg b=30.5deg+-3deg

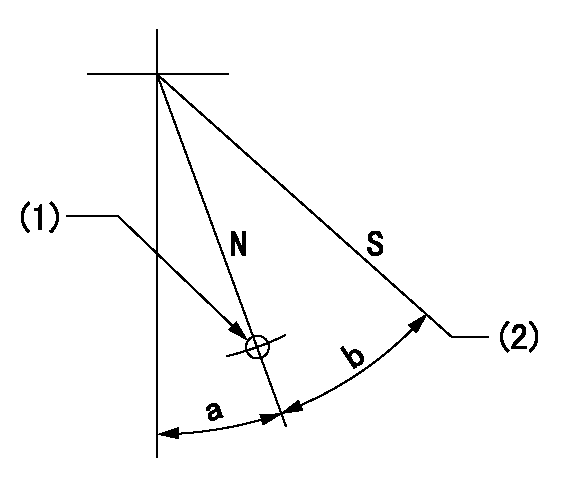

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Use the pin at R = aa

(2)Set the stopper bolt so that speed = bb and rack position = cc. (Confirm non-injection.)

----------

aa=40mm bb=0r/min cc=1+-0.3mm

----------

a=18deg+-5deg b=44deg+-5deg

----------

aa=40mm bb=0r/min cc=1+-0.3mm

----------

a=18deg+-5deg b=44deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Position of timer's threaded hole at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=9deg

----------

a=(100deg)

----------

aa=9deg

----------

a=(100deg)

Information:

Example of Pulse Width ModulationRated Fuel Position("Rated Fuel Pos" on ECAP) - this indicates the maximum allowable fuel position (longest injection pulse). It will produce rated power for this engine configuration.Reference VoltageA regulated, unchanging voltage supplied by the ECM to a sensor. The reference voltage is used by the sensor to generate a signal voltage. Remote Station OperationEngine speed control from a location outside of the vehicle cab, typically for some type of PTO operation for pumping or other application using engine power.SensorA device used to detect and convert a change in pressure, temperature, or mechanical movement into an electrical signal.Service Brake SwitchThis OEM supplied and installed switch is typically a pressure switch. This switch is normally closed with the pedal released. Depressing the brake will open the circuit.Service Engine Soon LampSometimes referred to as the "Diagnostic Lamp", it is used to alert the operator of the presence of an active event and is used to flash a diagnostic code.Service Program Module (SPM)A software program on a factory programmable computer chip, designed to adapt an Electronic Service Tool to a specific application.Short CircuitA condition where an electrical circuit is unintentionally connected to an undesirable point. Example: a wire which rubs against a vehicle frame until it wears off its insulation and makes electrical contact with the frame.SignalA voltage or waveform used to transmit information typically from a sensor to the ECM.Speed "burp"A sudden, brief, unwanted change in engine rpm.Speed/Timing SensorA sensor that measures crankshaft position, direction of rotation and engine rpm and sends signal to ECM.Standard SAE Diagnostic Communications Data LinkRefer to ATA Data Link.SubsystemAs used here, it is a part of the Electronic System that relates to a particular function, for instance throttle subsystem, etc.Supply VoltageA constant voltage supplied to a component to provide electrical power for its operation. It may be generated by the ECM, or it may be vehicle battery voltage supplied by the vehicle wiring.System Configuration ParametersParameters which affect power rating family or emissions."T" HarnessA test harness designed to connect into vehicle or engine harness which allows normal circuit operation while providing a breakout or "T" to measure signals.Throttle PositionThe ECM interpretation of the signal from the Throttle Position Sensor.Throttle Position SensorAn electronic sensor which is connected to the accelerator pedal and sends a Pulse Width Modulated Signal to the ECM.Timing CalibrationThe adjustment of an electrical signal as a means of correcting timing error between the crankshaft and camshaft. Refer to Speed/Timing Sensor.Torque LimitProgrammable parameter which limits the maximum torque based on PTO Configuration and operation.Total TattletaleTotal number of changes to all Customer Specified Parameters stored in the ECM.Transmission StyleProgrammable parameter that designates the type of transmission in the vehicle and the circuits connected to the ECM. The transmission relay, cruise control, idle/PTO, and exhaust brake operation are affected by this parameter setting.Trip RecorderAn after market device dedicated to recording vehicle and engine operating parameters during vehicle service. Used to analyze driving habits and produce driver logs.Vehicle Speed CalibrationProgrammable parameter used by the ECM