Information injection-pump assembly

BOSCH

9 400 616 888

9400616888

ZEXEL

106671-5910

1066715910

NISSAN-DIESEL

1679096610

1679096610

Rating:

Service parts 106671-5910 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

16600-96609

12.

Open Pre:MPa(Kqf/cm2)

17.7{180}/22.6{230}

15.

NOZZLE SET

Include in #1:

106671-5910

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 400 616 888

9400616888

ZEXEL

106671-5910

1066715910

NISSAN-DIESEL

1679096610

1679096610

Zexel num

Bosch num

Firm num

Name

106671-5910

9 400 616 888

1679096610 NISSAN-DIESEL

INJECTION-PUMP ASSEMBLY

PF6TA K 14CA INJECTION PUMP ASSY PE6P,6PD PE

PF6TA K 14CA INJECTION PUMP ASSY PE6P,6PD PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

134424-0020

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.9

3.85

3.95

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

11.3

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

179.5

177.5

181.5

Max. variation between cylinders

%

0

-4

4

Basic

*

Fixing the lever

*

Boost pressure

kPa

89.3

89.3

Boost pressure

mmHg

670

670

Injection quantity adjustment_02

Adjusting point

D

Rack position

6+-0.5

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

11.5

10.5

12.5

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Boost compensator adjustment

Pump speed

r/min

500

500

500

Rack position

9.3

Boost pressure

kPa

6.7

1.4

12

Boost pressure

mmHg

50

10

90

Boost compensator adjustment_02

Pump speed

r/min

500

500

500

Rack position

(11.3)

Boost pressure

kPa

77.3

74.6

80

Boost pressure

mmHg

580

560

600

Timer adjustment

Pump speed

r/min

750--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

700

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1050

Advance angle

deg.

2

1.5

2.5

Remarks

Finish

Finish

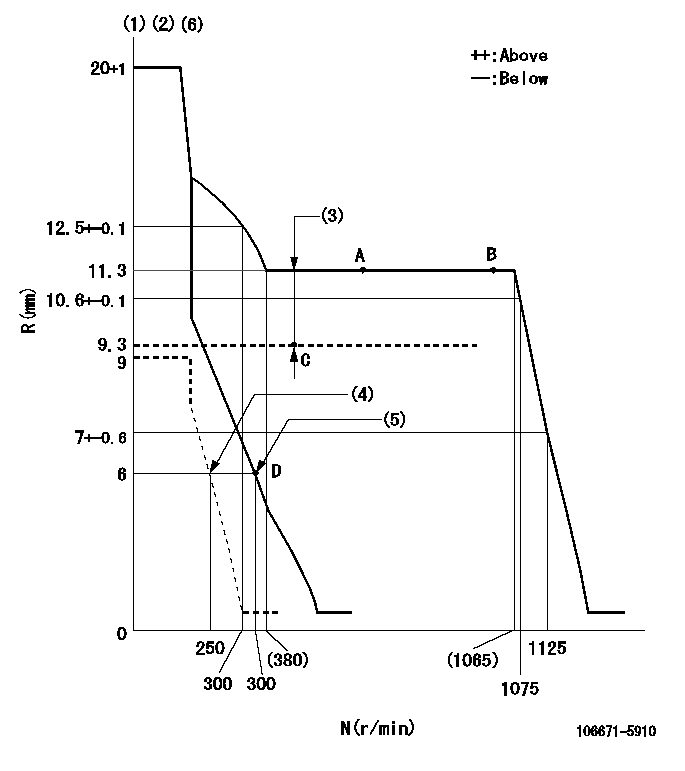

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)Boost compensator stroke: BCL

(4)Set idle sub-spring

(5)Main spring setting

(6)Perform governor adjustment at an ambient temperature of at least 15 deg C (boost compensator start spring is shape memory alloy).

----------

K=9 BCL=(2)mm

----------

----------

K=9 BCL=(2)mm

----------

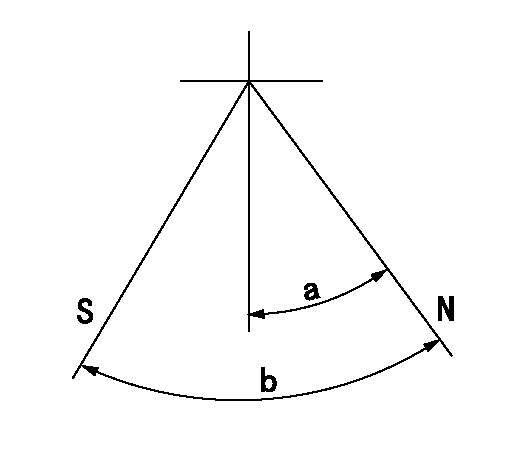

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=4deg+-5deg b=22deg+-5deg

----------

----------

a=4deg+-5deg b=22deg+-5deg

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=26deg+-5deg b=53deg+-5deg

----------

----------

a=26deg+-5deg b=53deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(25deg)

----------

----------

a=(25deg)

Information:

Outside Leaks

Possible Causes/Corrections Leaks In Hoses Or ConnectionsCheck all hoses and connections for visual signs of leakage. If no leaks are seen, look for damage to hoses or loose clamps. Leaks In The Radiator And/Or Expansion TankPut pressure to the radiator and/or expansion tank with the 9S8140 Cooling System Pressurizing Pump Group and check for leaks. Leaks In The HeaterPut pressure to the cooling system with the 9S8140 Cooling System Pressurizing Pump Group and check the heater for leaks. Leaks In The Water PumpCheck the water pump for leaks before starting the engine, then start the engine and look for leaks. If there are leaks at the water pump, repair or install a new water pump. Cylinder Head Gasket LeakageLook for leaks along the surface of the cylinder head gasket. If you see leaks, install a new head gasket.Refer to Special Instruction, SEHS9565, 3306 Cylinder Head To Block Joint Repair Procedure for additional information on Combustion Gas Leakage Tests.Coolant Leaks At The Overflow Tube

Possible Causes/Corrections Defective Pressure Cap Or Relief ValveCheck the sealing surfaces of the pressure cap and the radiator to be sure the cap is sealing correctly. Check the opening pressure and sealing ability of the pressure cap or relief valve with the 9S8140 Cooling System Pressurizing Pump Group. Engine Runs Too HotIf coolant temperature is too high, pressure will be high enough to move the cap off of the sealing surface in the radiator and cause coolant loss through the overflow tube. See "Overheating" in Cooling System Troubleshooting Section. Expansion Tank Too Small Or Installed WrongThe expansion tank can be either a part of the radiator or it can be installed separately from the radiator. The expansion tank must be large enough to hold the expansion of the coolant as it gets warm or has sudden changes in pressure. Make sure the expansion tank is installed correctly, and the size is according to the recommendations of the truck manufacturer. Cylinder Head Gasket Leakage Or Crack(s) In Cylinder Head Or Cylinder BlockRemove the radiator cap and, with the engine running, look for air bubbles in the coolant. Bubbles in the coolant are a sign of probable leakage at the head gasket. Remove the cylinder head from the engine. Check cylinder head, cylinder walls and head gasket surface of the cylinder block for cracks. When the head is installed, use a new head gasket, spacer plate gasket, water seals, and O-ring seals.Inside Leakage

Possible Causes/Corrections Cylinder Head Gasket LeakageIf the cylinder head gasket leaks between a water passage and an opening into the crankcase, coolant will get into the crankcase.Refer to Special Instruction, SEHS9565, 3306 Cylinder Head To Block Joint Repair Procedure for additional information on Combustion Gas Leakage Tests. Crack(s) In Cylinder HeadCrack(s) in the upper surface of the cylinder head, or an area between a water passage and an opening into the crankcase, can allow coolant to get into the crankcase. Crack(s) In Cylinder BlockCrack(s) in the cylinder block between a water passage and the crankcase

Possible Causes/Corrections Leaks In Hoses Or ConnectionsCheck all hoses and connections for visual signs of leakage. If no leaks are seen, look for damage to hoses or loose clamps. Leaks In The Radiator And/Or Expansion TankPut pressure to the radiator and/or expansion tank with the 9S8140 Cooling System Pressurizing Pump Group and check for leaks. Leaks In The HeaterPut pressure to the cooling system with the 9S8140 Cooling System Pressurizing Pump Group and check the heater for leaks. Leaks In The Water PumpCheck the water pump for leaks before starting the engine, then start the engine and look for leaks. If there are leaks at the water pump, repair or install a new water pump. Cylinder Head Gasket LeakageLook for leaks along the surface of the cylinder head gasket. If you see leaks, install a new head gasket.Refer to Special Instruction, SEHS9565, 3306 Cylinder Head To Block Joint Repair Procedure for additional information on Combustion Gas Leakage Tests.Coolant Leaks At The Overflow Tube

Possible Causes/Corrections Defective Pressure Cap Or Relief ValveCheck the sealing surfaces of the pressure cap and the radiator to be sure the cap is sealing correctly. Check the opening pressure and sealing ability of the pressure cap or relief valve with the 9S8140 Cooling System Pressurizing Pump Group. Engine Runs Too HotIf coolant temperature is too high, pressure will be high enough to move the cap off of the sealing surface in the radiator and cause coolant loss through the overflow tube. See "Overheating" in Cooling System Troubleshooting Section. Expansion Tank Too Small Or Installed WrongThe expansion tank can be either a part of the radiator or it can be installed separately from the radiator. The expansion tank must be large enough to hold the expansion of the coolant as it gets warm or has sudden changes in pressure. Make sure the expansion tank is installed correctly, and the size is according to the recommendations of the truck manufacturer. Cylinder Head Gasket Leakage Or Crack(s) In Cylinder Head Or Cylinder BlockRemove the radiator cap and, with the engine running, look for air bubbles in the coolant. Bubbles in the coolant are a sign of probable leakage at the head gasket. Remove the cylinder head from the engine. Check cylinder head, cylinder walls and head gasket surface of the cylinder block for cracks. When the head is installed, use a new head gasket, spacer plate gasket, water seals, and O-ring seals.Inside Leakage

Possible Causes/Corrections Cylinder Head Gasket LeakageIf the cylinder head gasket leaks between a water passage and an opening into the crankcase, coolant will get into the crankcase.Refer to Special Instruction, SEHS9565, 3306 Cylinder Head To Block Joint Repair Procedure for additional information on Combustion Gas Leakage Tests. Crack(s) In Cylinder HeadCrack(s) in the upper surface of the cylinder head, or an area between a water passage and an opening into the crankcase, can allow coolant to get into the crankcase. Crack(s) In Cylinder BlockCrack(s) in the cylinder block between a water passage and the crankcase

Have questions with 106671-5910?

Group cross 106671-5910 ZEXEL

Nissan-Diesel

106671-5910

9 400 616 888

1679096610

INJECTION-PUMP ASSEMBLY

PF6TA

PF6TA