Information injection-pump assembly

BOSCH

9 400 616 874

9400616874

ZEXEL

106671-5730

1066715730

NISSAN-DIESEL

1671496501

1671496501

Rating:

Service parts 106671-5730 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

16600-96520

12.

Open Pre:MPa(Kqf/cm2)

22.6{230}

15.

NOZZLE SET

Include in #1:

106671-5730

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 400 616 874

9400616874

ZEXEL

106671-5730

1066715730

NISSAN-DIESEL

1671496501

1671496501

Zexel num

Bosch num

Firm num

Name

106671-5730

9 400 616 874

1671496501 NISSAN-DIESEL

INJECTION-PUMP ASSEMBLY

PE6TA K 14CA INJECTION PUMP ASSY PE6P,6PD PE

PE6TA K 14CA INJECTION PUMP ASSY PE6P,6PD PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

132424-0620

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.65

3.6

3.7

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

11.8

Pump speed

r/min

650

650

650

Average injection quantity

mm3/st.

166.5

164.5

168.5

Max. variation between cylinders

%

0

-4

4

Basic

*

Fixing the lever

*

Boost pressure

kPa

76

76

Boost pressure

mmHg

570

570

Hydraulic cylinder OFF

*

Injection quantity adjustment_02

Adjusting point

C

Rack position

6.7+-0.5

Pump speed

r/min

270

270

270

Average injection quantity

mm3/st.

15.5

14.5

16.5

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Hydraulic cylinder OFF

*

Injection quantity adjustment_03

Adjusting point

D

Rack position

9.75

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

110

107

113

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Hydraulic cylinder OFF

*

Boost compensator adjustment

Pump speed

r/min

400

400

400

Rack position

9.75

Boost pressure

kPa

20

18.7

21.3

Boost pressure

mmHg

150

140

160

Boost compensator adjustment_02

Pump speed

r/min

400

400

400

Rack position

11.8

Boost pressure

kPa

46

42

50

Boost pressure

mmHg

345

315

375

Boost compensator adjustment_03

Pump speed

r/min

400

400

400

Rack position

(12.8)

Boost pressure

kPa

62.7

62.7

62.7

Boost pressure

mmHg

470

470

470

Timer adjustment

Pump speed

r/min

875--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

825

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

925

Advance angle

deg.

1

0.5

1.5

Remarks

Finish

Finish

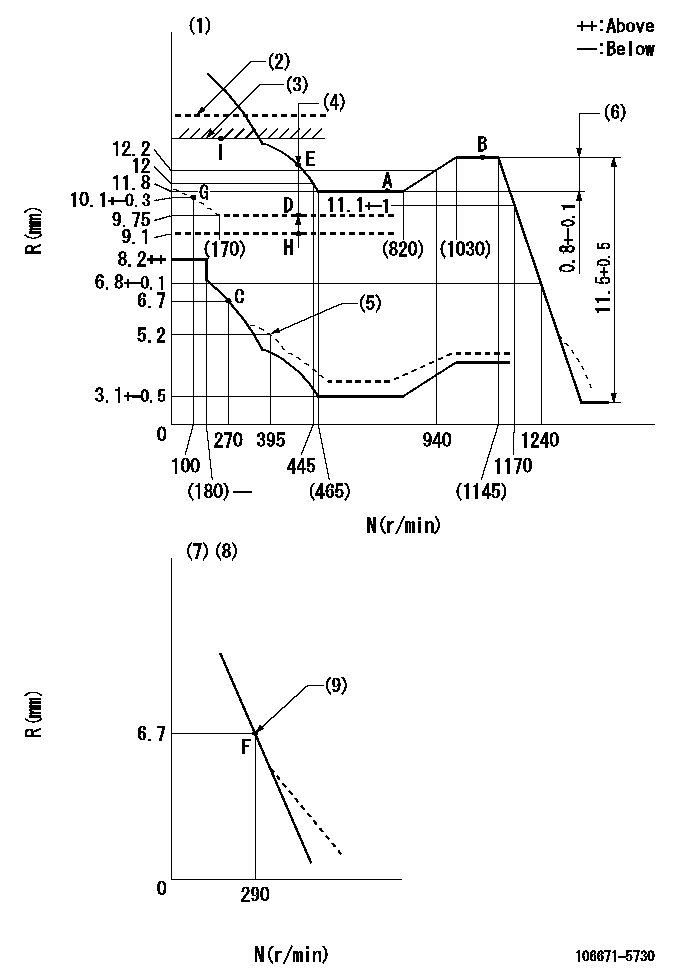

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Tolerance for racks not indicated: +-0.05mm.

(2)Solenoid boost compensator OFF: SBL

(3)Rack limit using the stop lever: R1

(4)Boost compensator stroke: BCL

(5)Damper spring setting

(6)Rack difference between N = N1 and N = N2

(7)Variable speed specification: idling adjustment

(8)Fix the lever at the full-load position at delivery.

(9)Main spring setting

----------

SBL=(13.1)mm R1=12.8+0.2mm BCL=(3.05)mm N1=1100r/min N2=650r/min

----------

----------

SBL=(13.1)mm R1=12.8+0.2mm BCL=(3.05)mm N1=1100r/min N2=650r/min

----------

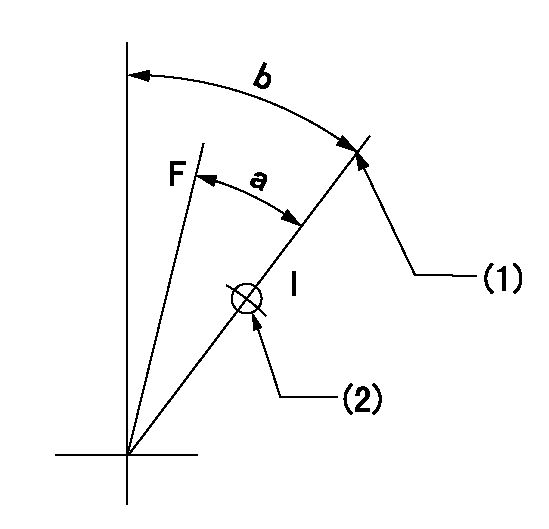

Speed control lever angle

F:Full speed

I:Idle

(1)Pump speed = aa

(2)Set the stopper bolt (fixed at full-load position at delivery.)

----------

aa=290r/min

----------

a=(16deg)+-5deg b=(8deg)+-5deg

----------

aa=290r/min

----------

a=(16deg)+-5deg b=(8deg)+-5deg

0000000901

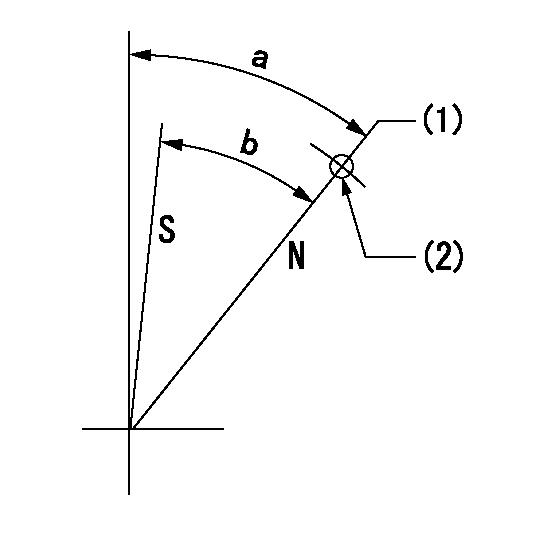

F:Full load

I:Idle

(1)Stopper bolt setting

(2)Use the hole at R = aa

----------

aa=42mm

----------

a=31.5deg+-3deg b=45deg+-5deg

----------

aa=42mm

----------

a=31.5deg+-3deg b=45deg+-5deg

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Rack position aa (pump speed bb r/min )

(2)Use the pin above R = cc

----------

aa=12.8+0.2mm bb=350r/min cc=40mm

----------

a=(42deg)+-5deg b=41deg+-5deg

----------

aa=12.8+0.2mm bb=350r/min cc=40mm

----------

a=(42deg)+-5deg b=41deg+-5deg

0000001501 BCS

(A) Screw for precise adjustment

(B) Pre-adjustment screw

(C) Control rack, rack decrease direction

(D) Rack limit

1. Solenoid boost compensator adjustment

(1)Supply DC: V1 to the solenoid terminals and confirm solenoid operation.

(2)With the solenoid ON, calculate L1 from the value of R1. [L1 = La - (10.5 - R1) +-0.2]

(3)Adjust (B) to obtain L1.

(4)Assemble the solenoid to the governor.

(5)With the solenoid ON, readjust (B) so that R1 is within the allowance a.

(6)With the solenoid OFF, perform all governor adjustments except rack limit adjustment.

(7)Set the pump speed at N1 and turn the solenoid ON.

(8)Adjust (A) so that R1 is within the allowance range a.

(9)Set the pump speed at N1 and fix the load lever in the full position

(10)Turn the solenoid switch ON and OFF several times and confirm that the difference in rack positions is within L2.

(11)Set the rack limit.

(12)Stamp the solenoid valve.

----------

V1=24V N1=400r/min N2=0r/min R1=9.1mm a=+-0.5mm La=28mm L1=26.6+-0.2mm L2=3.5~5mm

----------

----------

V1=24V N1=400r/min N2=0r/min R1=9.1mm a=+-0.5mm La=28mm L1=26.6+-0.2mm L2=3.5~5mm

----------

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(30deg)

----------

----------

a=(30deg)

Information:

Start By:a. remove engine balancer group (3114 Engines)b. remove oil pump (3116 Engines) 1. Remove bolts (1), the washers and bearing cap (2). Remove the lower main bearing half from the cap.

If the crankshaft is turned in the wrong direction during upper main bearing half removal, the tab of the bearing will be pushed between the crankshaft and the cylinder block. This can cause result in damage to either or both the crankshaft and the cylinder block.

Both the center and two end main journals have no oil hole. To remove these upper main bearing halves, put a thin piece of soft material, (that will not damage the crankshaft journal), against the end of the bearing half, opposite the tab. Hit the bearing with the soft material until the tab of the bearing is free from the groove in the cylinder block.2. Remove the upper half of the main bearings as follows: a. Turn the crankshaft until Tool (A) can be installed in the crankshaft journal. Install Tool (A) as shown.b. Turn the crankshaft in the direction which will push the upper main bearing half out, tab end first.c. Check the condition of the main bearings. Refer to "Guideline For Reusable Parts, Main & Connecting Rod Bearings", Form No. SEBF8009 and SEBD0531 as guide for checking bearing condition. The following steps are for the installation of the crankshaft main bearings.3. Clean the bearing surfaces in the cylinder block for the main bearings. Apply clean engine oil on the upper main bearing half. Do not put oil on the back side of the bearing. Using Tool (A), install the upper main bearing half (bearings with the oil holes) in the cylinder block. Be sure the tab on the back side of the bearing engages with the groove in the cylinder block.4. Clean the bearing surface of the main bearing caps. Install the lower main bearing half in the main bearing cap. Be sure the tab on the back side of the bearing engages with the groove in the main bearing cap. Apply clean engine oil on the lower main bearing half. Do no put oil on the back side of the bearing.5. Install the main bearing caps as follows:

Install the main bearing caps with the sequence number to the right, 1 through 5 (for the 4 cylinder) and 1 through 7 (for the 6 cylinder), front to rear.

a. Put main bearing caps (2) in position in the cylinder block with the sequence numbers in the correct positions.b. Apply clean engine oil to the threads of the main bearing cap mounting bolts and on the washer contact faces.c. Install main bearing cap mounting bolts (1) and the washers. Tighten both bolts of each main bearing cap to a torque of 54 7 N m (40 5 lb ft).d. Tighten the bolts and additional 1/4 90 5 degrees ( turn). 6. Check the end play of the crankshaft with Tool (B). The end play of the crankshaft

If the crankshaft is turned in the wrong direction during upper main bearing half removal, the tab of the bearing will be pushed between the crankshaft and the cylinder block. This can cause result in damage to either or both the crankshaft and the cylinder block.

Both the center and two end main journals have no oil hole. To remove these upper main bearing halves, put a thin piece of soft material, (that will not damage the crankshaft journal), against the end of the bearing half, opposite the tab. Hit the bearing with the soft material until the tab of the bearing is free from the groove in the cylinder block.2. Remove the upper half of the main bearings as follows: a. Turn the crankshaft until Tool (A) can be installed in the crankshaft journal. Install Tool (A) as shown.b. Turn the crankshaft in the direction which will push the upper main bearing half out, tab end first.c. Check the condition of the main bearings. Refer to "Guideline For Reusable Parts, Main & Connecting Rod Bearings", Form No. SEBF8009 and SEBD0531 as guide for checking bearing condition. The following steps are for the installation of the crankshaft main bearings.3. Clean the bearing surfaces in the cylinder block for the main bearings. Apply clean engine oil on the upper main bearing half. Do not put oil on the back side of the bearing. Using Tool (A), install the upper main bearing half (bearings with the oil holes) in the cylinder block. Be sure the tab on the back side of the bearing engages with the groove in the cylinder block.4. Clean the bearing surface of the main bearing caps. Install the lower main bearing half in the main bearing cap. Be sure the tab on the back side of the bearing engages with the groove in the main bearing cap. Apply clean engine oil on the lower main bearing half. Do no put oil on the back side of the bearing.5. Install the main bearing caps as follows:

Install the main bearing caps with the sequence number to the right, 1 through 5 (for the 4 cylinder) and 1 through 7 (for the 6 cylinder), front to rear.

a. Put main bearing caps (2) in position in the cylinder block with the sequence numbers in the correct positions.b. Apply clean engine oil to the threads of the main bearing cap mounting bolts and on the washer contact faces.c. Install main bearing cap mounting bolts (1) and the washers. Tighten both bolts of each main bearing cap to a torque of 54 7 N m (40 5 lb ft).d. Tighten the bolts and additional 1/4 90 5 degrees ( turn). 6. Check the end play of the crankshaft with Tool (B). The end play of the crankshaft

Have questions with 106671-5730?

Group cross 106671-5730 ZEXEL

Nissan-Diesel

106671-5730

9 400 616 874

1671496501

INJECTION-PUMP ASSEMBLY

PE6TA

PE6TA