Information injection-pump assembly

BOSCH

9 400 616 871

9400616871

ZEXEL

106671-5690

1066715690

NISSAN-DIESEL

1679096608

1679096608

Rating:

Service parts 106671-5690 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

1660096611

12.

Open Pre:MPa(Kqf/cm2)

18.6{190}/22.6{230}

14.

NOZZLE

Include in #1:

106671-5690

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 400 616 871

9400616871

ZEXEL

106671-5690

1066715690

NISSAN-DIESEL

1679096608

1679096608

Zexel num

Bosch num

Firm num

Name

106671-5690

9 400 616 871

1679096608 NISSAN-DIESEL

INJECTION-PUMP ASSEMBLY

PF6T24 K 14CA INJECTION PUMP ASSY PE6P,6PD PE

PF6T24 K 14CA INJECTION PUMP ASSY PE6P,6PD PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

134424-0020

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.9

3.85

3.95

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

12

Pump speed

r/min

1050

1050

1050

Average injection quantity

mm3/st.

175.5

173.5

177.5

Max. variation between cylinders

%

0

-4

4

Basic

*

Fixing the lever

*

Boost pressure

kPa

72

72

Boost pressure

mmHg

540

540

Injection quantity adjustment_02

Adjusting point

C

Rack position

6.5+-0.5

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

14.5

13.5

15.5

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Boost compensator adjustment

Pump speed

r/min

300

300

300

Rack position

9.6

Boost pressure

kPa

6.7

1.4

12

Boost pressure

mmHg

50

10

90

Boost compensator adjustment_02

Pump speed

r/min

300

300

300

Rack position

12

Boost pressure

kPa

37.3

34.6

40

Boost pressure

mmHg

280

260

300

Boost compensator adjustment_03

Pump speed

r/min

300

300

300

Rack position

(13.2)

Boost pressure

kPa

58.7

58.7

58.7

Boost pressure

mmHg

440

440

440

Timer adjustment

Pump speed

r/min

750--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

700

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1050

Advance angle

deg.

2

1.5

2.5

Remarks

Finish

Finish

Test data Ex:

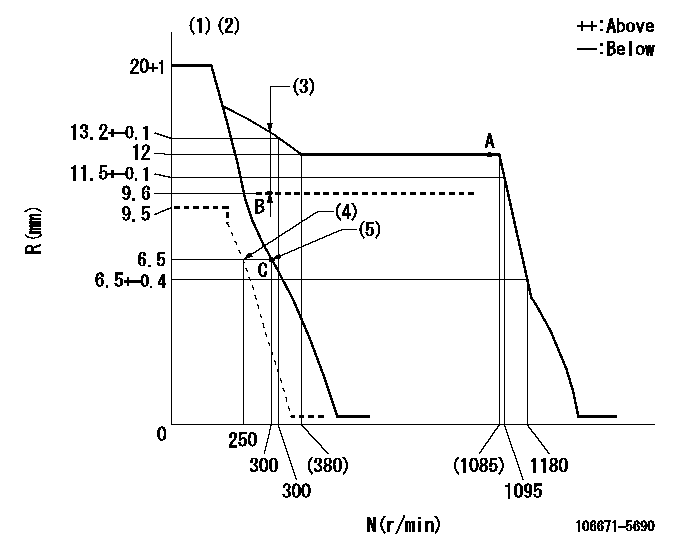

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)Boost compensator stroke: BCL

(4)Set idle sub-spring

(5)Main spring setting

----------

K=9 BCL=(3.6)mm

----------

----------

K=9 BCL=(3.6)mm

----------

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=(10deg)+-5deg b=(22deg)+-5deg

----------

----------

a=(10deg)+-5deg b=(22deg)+-5deg

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=26.5deg+-5deg b=53deg+-5deg

----------

----------

a=26.5deg+-5deg b=53deg+-5deg

0000001501 GOV FULL LOAD ADJUSTMENT

Title1:Full load stopper adjustment

Title2:Governor set speed

LABEL1:Distinguishing

LABEL2:Pump speed (r/min)

LABEL3:Ave. injection quantity (mm3/st)

LABEL4:Max. var. bet. cyl.

LABEL5:Remarks

LABEL6:Distinguishing

LABEL7:Governor set speed (r/min)

LABEL8:Maximum no-load speed (r/min)

LABEL9:Remarks

(1)Adjustment conditions are the same as those for measuring injection quantity.

(2)At high idle rack position L

----------

L=6.5mm

----------

a1=B a2=- a3=- a4=- r1=1050r/min r2=- r3=- r4=- Q1=175.5+-2mm3/st Q2=- Q3=- Q4=- c1=+-4% c2=- c3=- c4=- a5=21 a6=20 a7=19 a8=18 a9=17 a10=16 a11=15 a12=14 a13=- a14=- a15=- r5=1050r/min r6=1000r/min r7=950r/min r8=900r/min r9=850r/min r10=800r/min r11=750r/min r12=700r/min r13=- r14=- r15=- R5=1130+-26r/min R6=1075+-25r/min R7=1020+-23r/min R8=965+-22r/min R9=915+-22r/min R10=865+-20r/min R11=820+-18r/min R12=775+-18r/min R13=- R14=- R15=-

----------

L=6.5mm

----------

a1=B a2=- a3=- a4=- r1=1050r/min r2=- r3=- r4=- Q1=175.5+-2mm3/st Q2=- Q3=- Q4=- c1=+-4% c2=- c3=- c4=- a5=21 a6=20 a7=19 a8=18 a9=17 a10=16 a11=15 a12=14 a13=- a14=- a15=- r5=1050r/min r6=1000r/min r7=950r/min r8=900r/min r9=850r/min r10=800r/min r11=750r/min r12=700r/min r13=- r14=- r15=- R5=1130+-26r/min R6=1075+-25r/min R7=1020+-23r/min R8=965+-22r/min R9=915+-22r/min R10=865+-20r/min R11=820+-18r/min R12=775+-18r/min R13=- R14=- R15=-

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(20deg)

----------

----------

a=(20deg)

Information:

1. Remove the bolts that hold the cylinder head assembly to the cylinder block.

To prevent damage to the two cylinder head-to-cylinder block dowels, keep the cylinder head assembly level during removal and installation.

2. Fasten a hoist to the cylinder head assembly as shown. Carefully remove the cylinder head assembly from the cylinder block. Remove the cylinder head gasket. The weight of the cylinder head assembly can range from 50 to 75 kg (110 to 165 lb). The following steps are for the installation of the cylinder head assembly.3. Be sure the mating surface of the cylinder head assembly and the cylinder block are thoroughly clean.4. Put a new cylinder head gasket in position on the cylinder block. Be sure the head gasket is dry. Fasten a hoist to the cylinder head assembly, and put it in position on the cylinder block.

3114 Cylinder Head Tightening Sequence

3116 Cylinder Head Tightening Sequence Bolts (1) are large diameter bolts (M20). Bolts (2) are small diameter bolts (M10).5. Apply clean engine oil on the threads of the cylinder head assembly mounting bolts.6. Install the bolts that hold the cylinder head assembly to the cylinder block, and tighten them as follows: a. Tighten the large diameter bolts in the number sequence shown to a torque of 150 15 N m (110 11 lb ft).b. Tighten the large diameter bolts in the number sequence shown to a torque of 435 20 N m (320 15 lb ft).c. Retorque the large diameter bolts in the number sequence shown to a torque of 435 20 N m (320 15 lb ft).d. Tighten the small diameter bolts in the number sequence shown to a torque of 55 7 N m (41 5 lb ft).End By:a. install unit fuel injectorsb. install fuel control linkagec. install rocker arm assemblies and push rodsd. install inlet manifolde. install exhaust manifoldf. install fuel filter and fuel filter base

To prevent damage to the two cylinder head-to-cylinder block dowels, keep the cylinder head assembly level during removal and installation.

2. Fasten a hoist to the cylinder head assembly as shown. Carefully remove the cylinder head assembly from the cylinder block. Remove the cylinder head gasket. The weight of the cylinder head assembly can range from 50 to 75 kg (110 to 165 lb). The following steps are for the installation of the cylinder head assembly.3. Be sure the mating surface of the cylinder head assembly and the cylinder block are thoroughly clean.4. Put a new cylinder head gasket in position on the cylinder block. Be sure the head gasket is dry. Fasten a hoist to the cylinder head assembly, and put it in position on the cylinder block.

3114 Cylinder Head Tightening Sequence

3116 Cylinder Head Tightening Sequence Bolts (1) are large diameter bolts (M20). Bolts (2) are small diameter bolts (M10).5. Apply clean engine oil on the threads of the cylinder head assembly mounting bolts.6. Install the bolts that hold the cylinder head assembly to the cylinder block, and tighten them as follows: a. Tighten the large diameter bolts in the number sequence shown to a torque of 150 15 N m (110 11 lb ft).b. Tighten the large diameter bolts in the number sequence shown to a torque of 435 20 N m (320 15 lb ft).c. Retorque the large diameter bolts in the number sequence shown to a torque of 435 20 N m (320 15 lb ft).d. Tighten the small diameter bolts in the number sequence shown to a torque of 55 7 N m (41 5 lb ft).End By:a. install unit fuel injectorsb. install fuel control linkagec. install rocker arm assemblies and push rodsd. install inlet manifolde. install exhaust manifoldf. install fuel filter and fuel filter base

Have questions with 106671-5690?

Group cross 106671-5690 ZEXEL

Nissan-Diesel

Nissan-Diesel

Nissan-Diesel

Nissan-Diesel

106671-5690

9 400 616 871

1679096608

INJECTION-PUMP ASSEMBLY

PF6T24

PF6T24