Information injection-pump assembly

ZEXEL

106671-5680

1066715680

Rating:

Service parts 106671-5680 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

16600-96009

12.

Open Pre:MPa(Kqf/cm2)

17.7{180}/22.6{230}

15.

NOZZLE SET

Include in #1:

106671-5680

as INJECTION-PUMP ASSEMBLY

Cross reference number

ZEXEL

106671-5680

1066715680

Zexel num

Bosch num

Firm num

Name

106671-5680

INJECTION-PUMP ASSEMBLY

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

134424-0020

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.9

3.85

3.95

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

11.3

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

180.5

178.5

182.5

Max. variation between cylinders

%

0

-4

4

Basic

*

Fixing the lever

*

Boost pressure

kPa

86.6

86.6

Boost pressure

mmHg

650

650

Injection quantity adjustment_02

Adjusting point

D

Rack position

6.4+-0.5

Pump speed

r/min

375

375

375

Average injection quantity

mm3/st.

18.5

17.5

19.5

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Boost compensator adjustment

Pump speed

r/min

500

500

500

Rack position

9.35

Boost pressure

kPa

6.7

1.4

12

Boost pressure

mmHg

50

10

90

Boost compensator adjustment_02

Pump speed

r/min

500

500

500

Rack position

(11.3)

Boost pressure

kPa

77.3

74.6

80

Boost pressure

mmHg

580

560

600

Timer adjustment

Pump speed

r/min

750--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

700

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1050

Advance angle

deg.

2

1.5

2.5

Remarks

Finish

Finish

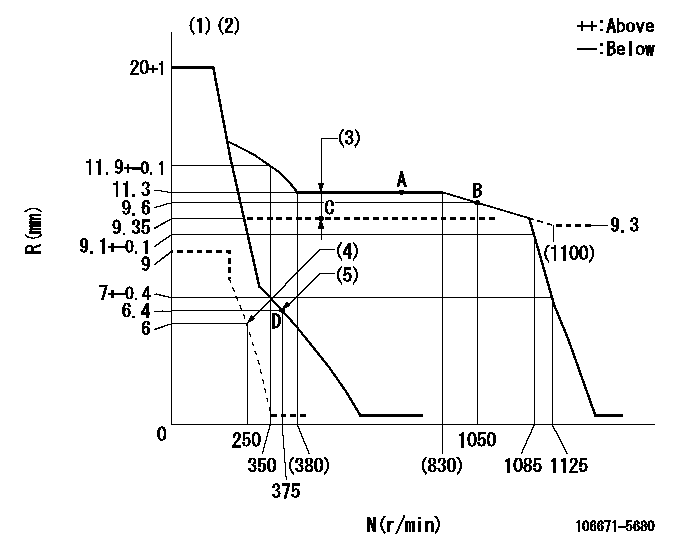

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)Boost compensator stroke: BCL

(4)Set idle sub-spring

(5)Main spring setting

----------

K=18 BCL=(1.95)mm

----------

----------

K=18 BCL=(1.95)mm

----------

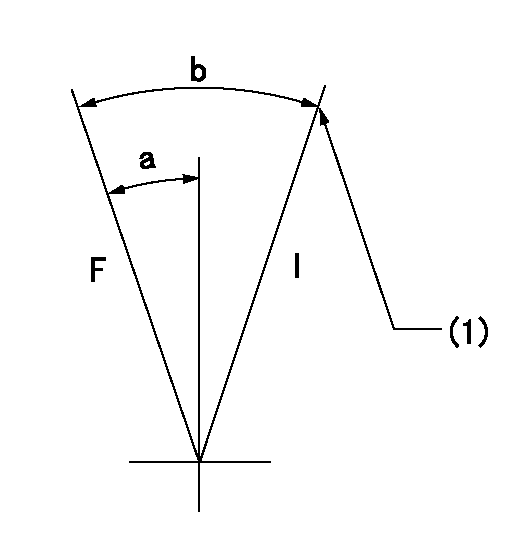

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=13deg+-5deg b=21deg+-5deg

----------

----------

a=13deg+-5deg b=21deg+-5deg

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=26deg+-5deg b=53deg+-5deg

----------

----------

a=26deg+-5deg b=53deg+-5deg

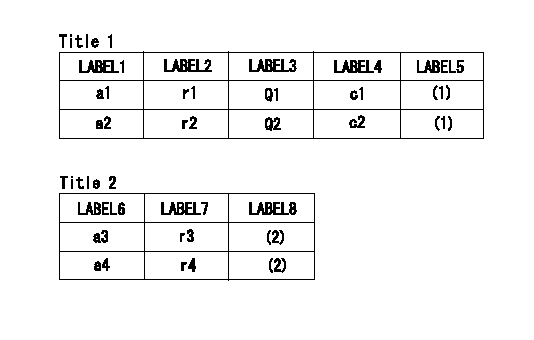

0000001501 GOV FULL LOAD ADJUSTMENT

Title1:Full load stopper adjustment

Title2:Governor set speed

LABEL1:Distinguishing

LABEL2:Pump speed (r/min)

LABEL3:Ave. injection quantity (mm3/st)

LABEL4:Max. var. bet. cyl.

LABEL5:Remarks

LABEL6:Distinguishing

LABEL7:Governor set speed (r/min)

LABEL8:Remarks

(1)Adjustment conditions are the same as those for measuring injection quantity.

(2)-

----------

----------

a1=B a2= r1=700r/min r2= Q1=180.5+-2mm3/st Q2= c1=+-4% c2= a3=21 a4=20 r3=1050r/min r4=1000r/min

----------

----------

a1=B a2= r1=700r/min r2= Q1=180.5+-2mm3/st Q2= c1=+-4% c2= a3=21 a4=20 r3=1050r/min r4=1000r/min

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(20deg)

----------

----------

a=(20deg)

Information:

Start By:a. remove rocker arm assemblies and push rods 1. Remove injector hold down bolt (1).

Do not pry on the injector hold down bracket. Damage to the injector could occur. The injector has a notch in it on the side opposite the rack. This notch is used for prying the injector loose. Also, do not move the fuel injector rack without the injector spring slightly compressed. Damage to the injector could occur.

2. Use Tool (A) to loosen the fuel injector; then rotate the fuel injector to disengage the injector rack from the fuel control linkage. Remove the fuel injector. Be sure both O-ring seals (2) are on the fuel injector. The following steps are for the installation of the unit fuel injectors.3. Check the condition of O-ring seals (2). If the seals are damaged, use new parts for replacement. Install the O-ring seals on in the fuel injector.4. Lubricate the O-ring seals on the fuel injector with clean engine oil.5. Position the fuel injector in the cylinder head assembly; then rotate it to engage the injector rack with the fuel control linkage. Push down on the top of the fuel injector so the O-ring seals slide into the bore in the cylinder head assembly. Be sure the fuel injector is seated properly before installing bolt (1) that holds it in position. Do not use bolt (1) to pull the fuel injector down into the cylinder head assembly.6. Install bolt (1), and tighten it.7. After installation of the rocker arm assemblies and push rods, Check and/or adjust the following: Injector Synchronization, Fuel Setting, Fuel Timing, Valve Lash. See the 3114 & 3116 Diesel Truck Engines Systems Operation Testing & Adjusting module, Form No. SENR6437 to check and/or adjust the above items.End By:a. install rocker arm assemblies and push rods

Do not pry on the injector hold down bracket. Damage to the injector could occur. The injector has a notch in it on the side opposite the rack. This notch is used for prying the injector loose. Also, do not move the fuel injector rack without the injector spring slightly compressed. Damage to the injector could occur.

2. Use Tool (A) to loosen the fuel injector; then rotate the fuel injector to disengage the injector rack from the fuel control linkage. Remove the fuel injector. Be sure both O-ring seals (2) are on the fuel injector. The following steps are for the installation of the unit fuel injectors.3. Check the condition of O-ring seals (2). If the seals are damaged, use new parts for replacement. Install the O-ring seals on in the fuel injector.4. Lubricate the O-ring seals on the fuel injector with clean engine oil.5. Position the fuel injector in the cylinder head assembly; then rotate it to engage the injector rack with the fuel control linkage. Push down on the top of the fuel injector so the O-ring seals slide into the bore in the cylinder head assembly. Be sure the fuel injector is seated properly before installing bolt (1) that holds it in position. Do not use bolt (1) to pull the fuel injector down into the cylinder head assembly.6. Install bolt (1), and tighten it.7. After installation of the rocker arm assemblies and push rods, Check and/or adjust the following: Injector Synchronization, Fuel Setting, Fuel Timing, Valve Lash. See the 3114 & 3116 Diesel Truck Engines Systems Operation Testing & Adjusting module, Form No. SENR6437 to check and/or adjust the above items.End By:a. install rocker arm assemblies and push rods

Have questions with 106671-5680?

Group cross 106671-5680 ZEXEL

Nissan-Diesel

Nissan-Diesel

Nissan-Diesel

106671-5680

INJECTION-PUMP ASSEMBLY