Information injection-pump assembly

BOSCH

9 400 616 863

9400616863

ZEXEL

106671-5550

1066715550

NISSAN-DIESEL

1679096604

1679096604

Rating:

Service parts 106671-5550 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

16600-96609

12.

Open Pre:MPa(Kqf/cm2)

17.7{180}/22.6{230}

15.

NOZZLE SET

Include in #1:

106671-5550

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 400 616 863

9400616863

ZEXEL

106671-5550

1066715550

NISSAN-DIESEL

1679096604

1679096604

Zexel num

Bosch num

Firm num

Name

106671-5550

9 400 616 863

1679096604 NISSAN-DIESEL

INJECTION-PUMP ASSEMBLY

PF6TA * K

PF6TA * K

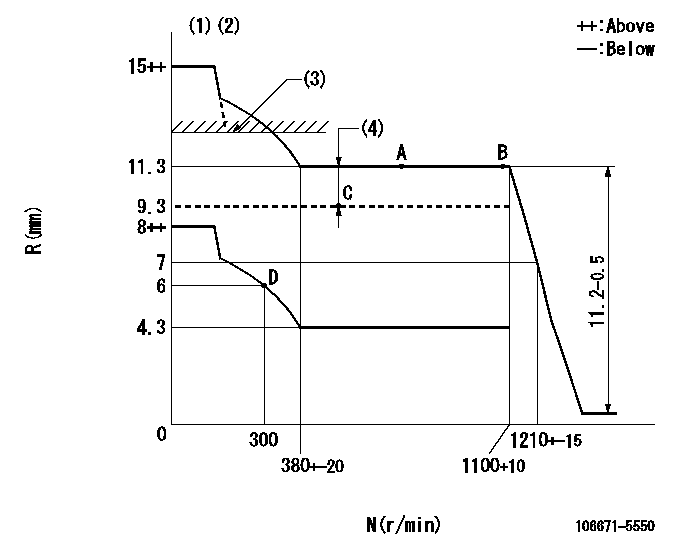

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

134424-0020

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.9

3.85

3.95

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

11.3

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

179.5

177.5

181.5

Max. variation between cylinders

%

0

-4

4

Basic

*

Fixing the lever

*

Boost pressure

kPa

86.6

86.6

Boost pressure

mmHg

650

650

Injection quantity adjustment_02

Adjusting point

D

Rack position

6+-0.5

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

11.5

10.5

12.5

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Boost compensator adjustment

Pump speed

r/min

500

500

500

Rack position

9.3

Boost pressure

kPa

6.7

1.4

12

Boost pressure

mmHg

50

10

90

Boost compensator adjustment_02

Pump speed

r/min

500

500

500

Rack position

(11.3)

Boost pressure

kPa

77.3

74.6

80

Boost pressure

mmHg

580

560

600

Timer adjustment

Pump speed

r/min

750--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

700

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1050

Advance angle

deg.

2

1.5

2.5

Remarks

Finish

Finish

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Adjust with speed control lever at full position (minimum-maximum speed specification)

(2)Target notch: K

(3)Boost compensator excessive fuel lever at operation: L1 (at 0 boost pressure)

(4)Boost compensator stroke: BCL

----------

K=16 L1=12.5+0.2mm BCL=(2)mm

----------

----------

K=16 L1=12.5+0.2mm BCL=(2)mm

----------

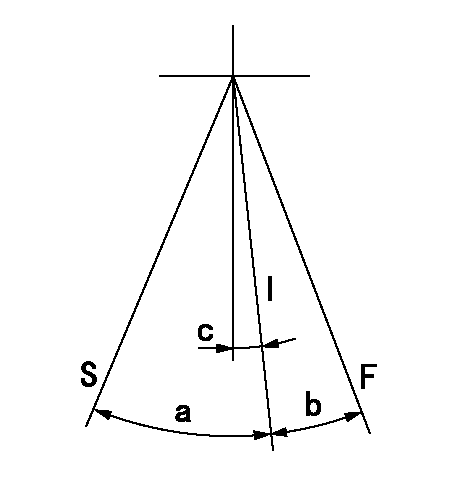

Speed control lever angle

F:Full speed

----------

----------

a=7deg+-5deg

----------

----------

a=7deg+-5deg

0000000901

F:Full load

I:Idle

S:Stop

----------

----------

a=26deg+-3deg b=22deg+-5deg c=2deg+-5deg

----------

----------

a=26deg+-3deg b=22deg+-5deg c=2deg+-5deg

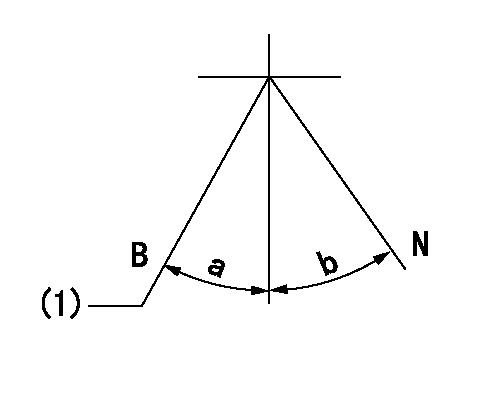

0000001101

N:Normal

B:When boosted

(1)Rack position = aa at boost pressure 0.

----------

aa=12.5+0.2mm

----------

a=(17deg) b=(18deg)

----------

aa=12.5+0.2mm

----------

a=(17deg) b=(18deg)

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(20deg)

----------

----------

a=(20deg)

Information:

Start By:a. remove cylinder head assemblyb. remove front housing groupc. remove flywheel housingd. remove crankshaft rear seal assemblye. remove piston and connecting rod assemblies 1. Remove bolts (1). Remove main bearing caps (2). Remove thrust bearings (3) from the center main. Main bearing caps are identified by numbers one through seven. Unmarked caps should be marked by stamping the appropriate number toward the right side on the bottom prior to the removal. 2. Install a suitable size bolt in each end of the crankshaft as shown. Fasten two lifting straps (4) to the bolts in the crankshaft and to a hoist as shown. Carefully, remove the crankshaft. The appropriate weight of the crankshaft is 129 kg (285 lb).3. Remove the upper portions of the main bearings. The following steps are for the installation of the crankshaft.

Be sure the main bearing tabs engage with the grooves in the block and cap.

4. Position the upper portion of the main bearings in the cylinder block. Lower the main bearing portion in caps (2). Be sure everything is clean and only the bearing face is lubricated with clean engine oil.5. Fasten a hoist to the crankshaft, and position it in the cylinder block. 6. Install thrust bearings (3).7. Install main bearing caps (2) with the part numbers toward the right hand side of the cylinder block. Take care to ensure the caps are numbered one through seven from the front of the engine. Put clean engine oil or molylube on the bolt threads and the washer face; then install bolts (1). Tighten the bolts on the side where the main bearing tabs are located to a torque of 95 5 N m (70 4 lb ft). Tighten the bolts on the opposite side to a torque of 95 5 N m (70 4 lb ft).8. Put a mark on each bolt head and the bearing caps. Turn the bolts that are opposite the main bearing tabs an additional 90° 5° turn. Then turn the bolts on the side where the main bearing tabs are located an additional 90° 5° turn.

Typical Example9. Use tooling (A) to measure crankshaft end play. The crankshaft end play must be 0.10 to 0.50 mm (.004 to .020 in).End By:a. install piston and connecting rod assembliesb. install crankshaft rear seal assemblyc. install flywheel housingd. install front housing groupe. install cylinder head assembly

Be sure the main bearing tabs engage with the grooves in the block and cap.

4. Position the upper portion of the main bearings in the cylinder block. Lower the main bearing portion in caps (2). Be sure everything is clean and only the bearing face is lubricated with clean engine oil.5. Fasten a hoist to the crankshaft, and position it in the cylinder block. 6. Install thrust bearings (3).7. Install main bearing caps (2) with the part numbers toward the right hand side of the cylinder block. Take care to ensure the caps are numbered one through seven from the front of the engine. Put clean engine oil or molylube on the bolt threads and the washer face; then install bolts (1). Tighten the bolts on the side where the main bearing tabs are located to a torque of 95 5 N m (70 4 lb ft). Tighten the bolts on the opposite side to a torque of 95 5 N m (70 4 lb ft).8. Put a mark on each bolt head and the bearing caps. Turn the bolts that are opposite the main bearing tabs an additional 90° 5° turn. Then turn the bolts on the side where the main bearing tabs are located an additional 90° 5° turn.

Typical Example9. Use tooling (A) to measure crankshaft end play. The crankshaft end play must be 0.10 to 0.50 mm (.004 to .020 in).End By:a. install piston and connecting rod assembliesb. install crankshaft rear seal assemblyc. install flywheel housingd. install front housing groupe. install cylinder head assembly

Have questions with 106671-5550?

Group cross 106671-5550 ZEXEL

Nissan-Diesel

Nissan-Diesel

Nissan-Diesel

106671-5550

9 400 616 863

1679096604

INJECTION-PUMP ASSEMBLY

PF6TA

PF6TA