Information injection-pump assembly

BOSCH

9 400 610 859

9400610859

ZEXEL

106671-5480

1066715480

NISSAN-DIESEL

1671396963

1671396963

Rating:

Service parts 106671-5480 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

16600-96610

12.

Open Pre:MPa(Kqf/cm2)

22.6{230}

15.

NOZZLE SET

Include in #1:

106671-5480

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 400 610 859

9400610859

ZEXEL

106671-5480

1066715480

NISSAN-DIESEL

1671396963

1671396963

Zexel num

Bosch num

Firm num

Name

106671-5480

9 400 610 859

1671396963 NISSAN-DIESEL

INJECTION-PUMP ASSEMBLY

PF6TA K 14CA INJECTION PUMP ASSY PE6P,6PD PE

PF6TA K 14CA INJECTION PUMP ASSY PE6P,6PD PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

132424-0620

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.9

3.85

3.95

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

10.7

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

163

161

165

Max. variation between cylinders

%

0

-4

4

Basic

*

Fixing the lever

*

Boost pressure

kPa

66.7

66.7

Boost pressure

mmHg

500

500

Injection quantity adjustment_02

Adjusting point

D

Rack position

9.05

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

116

113

119

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_03

Adjusting point

E

Rack position

6+-0.5

Pump speed

r/min

260

260

260

Average injection quantity

mm3/st.

14.5

13.2

15.8

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Boost compensator adjustment

Pump speed

r/min

400

400

400

Rack position

9.05

Boost pressure

kPa

13.3

12

14.6

Boost pressure

mmHg

100

90

110

Boost compensator adjustment_02

Pump speed

r/min

400

400

400

Rack position

11.2+0.2

Boost pressure

kPa

53.3

53.3

53.3

Boost pressure

mmHg

400

400

400

Timer adjustment

Pump speed

r/min

-

Advance angle

deg.

0

0

0

Remarks

Measure speed (beginning of operation).

Measure speed (beginning of operation).

Timer adjustment_02

Pump speed

r/min

-

Advance angle

deg.

1

0.5

1.5

Remarks

Measure the actual speed, stop

Measure the actual speed, stop

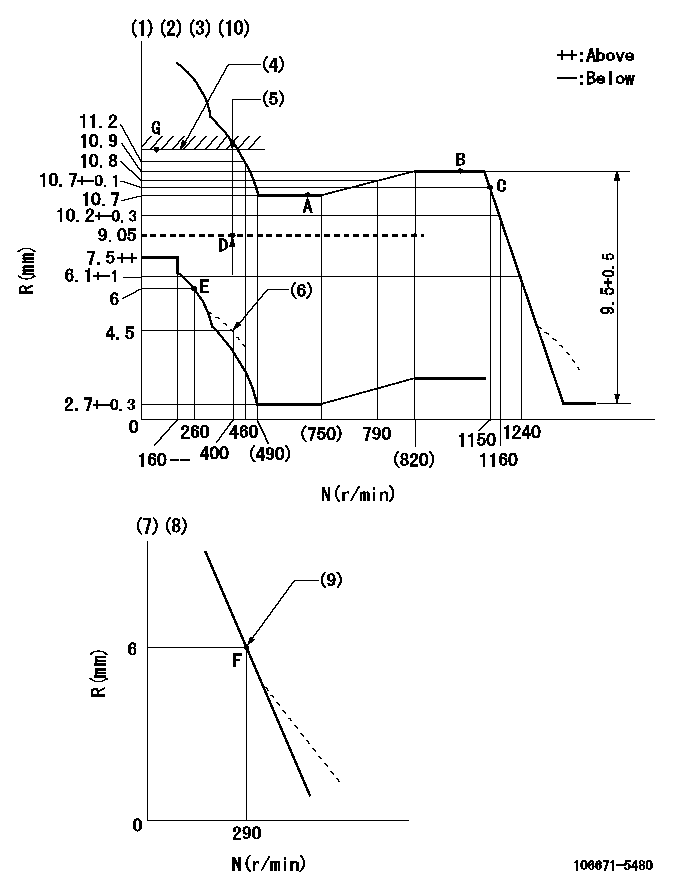

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Lever ratio: RT

(2)Target shim dimension: TH

(3)Tolerance for racks not indicated: +-0.05mm.

(4)Rack limit using the stop lever: R1

(5)Boost compensator stroke: BCL

(6)Damper spring setting

(7)Variable speed specification: idling adjustment

(8)Fix the lever at the full-load position at delivery.

(9)Main spring setting

(10)Perform governor adjustment at an ambient temperature of at least 15 deg C (boost compensator start spring is shape memory alloy).

----------

RT=1 TH=2.2mm R1=11.2+0.2mm BCL=(2.25)mm

----------

----------

RT=1 TH=2.2mm R1=11.2+0.2mm BCL=(2.25)mm

----------

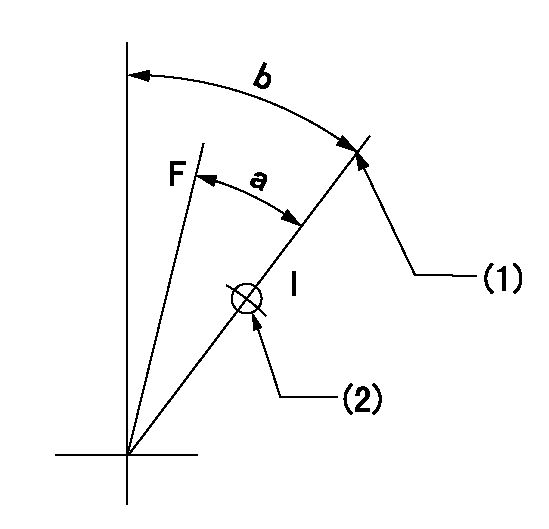

Speed control lever angle

F:Full speed

I:Idle

(1)Pump speed = aa

(2)Set the stopper bolt (fixed at full-load position at delivery.)

----------

aa=290r/min

----------

a=14deg+-5deg b=4deg+-5deg

----------

aa=290r/min

----------

a=14deg+-5deg b=4deg+-5deg

0000000901

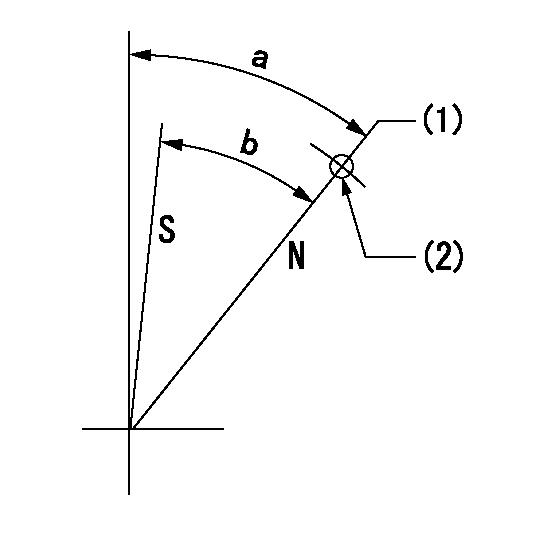

F:Full load

I:Idle

(1)Stopper bolt setting

(2)Use the hole at R = aa

----------

aa=42mm

----------

a=29.5deg+-3deg b=45deg+-5deg

----------

aa=42mm

----------

a=29.5deg+-3deg b=45deg+-5deg

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Rack position = aa

(2)Use the pin at R = bb

----------

aa=11.2+0.2mm bb=40mm

----------

a=37.5deg+-5deg b=35.5deg+-5deg

----------

aa=11.2+0.2mm bb=40mm

----------

a=37.5deg+-5deg b=35.5deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(20deg)

----------

----------

a=(20deg)

Information:

Grounding Practices

Proper grounding for vehicle and engine electrical systems is necessary for proper vehicle performance and reliability. Improper grounding will result in uncontrolled and unreliable electrical circuit paths.Uncontrolled engine electrical circuit paths can result in damage to main bearings, crankshaft journal surfaces, and aluminum components.Uncontrolled electrical circuit paths can cause electrical noise which may degrade vehicle and radio performance.To insure proper functioning of the vehicle and engine electrical systems, an engine-to-frame ground strap with a direct path to the battery must be used. This may be provided by way of a starter motor ground, a frame to starter motor ground, or a direct frame to engine ground.In any case, an engine-to-frame ground strap must be run from the cylinder head grounding stud to the frame and negative battery post.

Cylinder Head-To-Battery (-) Ground

Alternate Cylinder Head-To-Battery (-) GroundThe cylinder head must have a wire ground to battery as shown in the above illustrations.Ground wires/straps should be combined at ground studs dedicated for ground use only. At "Every 12,500 miles (20 125 km) or 250 hours," Inspect/Check all engine grounds. All grounds should be tight and free of corrosion.All ground paths must be capable of carrying any conceivable fault currents, and an awg # 0 or larger wire is recommended for the cylinder head grounding strap.The engine alternator should be battery (-) grounded with a wire size adequate to handle full alternator charging current.

When boost starting an engine, follow the instructions in "Engine Starting" in the "Operation Section" to properly start the engine.This engine may be equipped with a 12 or 24 volt starting system. Use only equal voltage for boost starting. The use of a welder or higher voltage will damage the electrical system.

The engine has several input components which are electronic. These components require an operating voltage.Unlike many electronic systems of the past, this engine is tolerant to common external sources of electrical noise, but electro-mechanical buzzers can cause disruptions in the power supply. If electro-mechanical buzzers are used anywhere on the vehicle, it is desirable to have the engine electronics (control group, throttle position sensor, and "check engine" lamp) powered directly from the battery system through a dedicated relay, and not through a common power bus with other key switch activated devices.Engine Electrical System

The electrical system can have three separate circuits: the charging circuit, the starting circuit and the low amperage circuit. Some of the electrical system components are used in more than one circuit. The battery (batteries), circuit breaker, ammeter, cables and wires from the battery are all common in each of the circuits.The charging circuit is in operation when the engine is running. An alternator makes electricity for the charging circuit. A voltage regulator in the circuit controls the electrical output to keep the battery at full charge.The starting circuit is in operation only when the start switch is activated.The low amperage circuit and the charging circuit are both connected through the ammeter. The starting circuit is not connected through the ammeter.Charging System Components

Alternator

The alternator is

Proper grounding for vehicle and engine electrical systems is necessary for proper vehicle performance and reliability. Improper grounding will result in uncontrolled and unreliable electrical circuit paths.Uncontrolled engine electrical circuit paths can result in damage to main bearings, crankshaft journal surfaces, and aluminum components.Uncontrolled electrical circuit paths can cause electrical noise which may degrade vehicle and radio performance.To insure proper functioning of the vehicle and engine electrical systems, an engine-to-frame ground strap with a direct path to the battery must be used. This may be provided by way of a starter motor ground, a frame to starter motor ground, or a direct frame to engine ground.In any case, an engine-to-frame ground strap must be run from the cylinder head grounding stud to the frame and negative battery post.

Cylinder Head-To-Battery (-) Ground

Alternate Cylinder Head-To-Battery (-) GroundThe cylinder head must have a wire ground to battery as shown in the above illustrations.Ground wires/straps should be combined at ground studs dedicated for ground use only. At "Every 12,500 miles (20 125 km) or 250 hours," Inspect/Check all engine grounds. All grounds should be tight and free of corrosion.All ground paths must be capable of carrying any conceivable fault currents, and an awg # 0 or larger wire is recommended for the cylinder head grounding strap.The engine alternator should be battery (-) grounded with a wire size adequate to handle full alternator charging current.

When boost starting an engine, follow the instructions in "Engine Starting" in the "Operation Section" to properly start the engine.This engine may be equipped with a 12 or 24 volt starting system. Use only equal voltage for boost starting. The use of a welder or higher voltage will damage the electrical system.

The engine has several input components which are electronic. These components require an operating voltage.Unlike many electronic systems of the past, this engine is tolerant to common external sources of electrical noise, but electro-mechanical buzzers can cause disruptions in the power supply. If electro-mechanical buzzers are used anywhere on the vehicle, it is desirable to have the engine electronics (control group, throttle position sensor, and "check engine" lamp) powered directly from the battery system through a dedicated relay, and not through a common power bus with other key switch activated devices.Engine Electrical System

The electrical system can have three separate circuits: the charging circuit, the starting circuit and the low amperage circuit. Some of the electrical system components are used in more than one circuit. The battery (batteries), circuit breaker, ammeter, cables and wires from the battery are all common in each of the circuits.The charging circuit is in operation when the engine is running. An alternator makes electricity for the charging circuit. A voltage regulator in the circuit controls the electrical output to keep the battery at full charge.The starting circuit is in operation only when the start switch is activated.The low amperage circuit and the charging circuit are both connected through the ammeter. The starting circuit is not connected through the ammeter.Charging System Components

Alternator

The alternator is

Have questions with 106671-5480?

Group cross 106671-5480 ZEXEL

Nissan-Diesel

Nissan-Diesel

Nissan-Diesel

Nissan-Diesel

106671-5480

9 400 610 859

1671396963

INJECTION-PUMP ASSEMBLY

PF6TA

PF6TA