Information injection-pump assembly

BOSCH

9 400 616 856

9400616856

ZEXEL

106671-5300

1066715300

NISSAN-DIESEL

1680196615

1680196615

Rating:

Cross reference number

BOSCH

9 400 616 856

9400616856

ZEXEL

106671-5300

1066715300

NISSAN-DIESEL

1680196615

1680196615

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131425-0120

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

RED3 control unit part number

407910-3

960

RED3 rack sensor specifications

mm

19

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

4.7

4.67

4.73

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.75 60.25

Cal 1-4 deg. 60 59.75 60.25

Difference between angles 2

Cyl.1-2 deg. 120 119.75 120.25

Cyl.1-2 deg. 120 119.75 120.25

Difference between angles 3

Cal 1-6 deg. 180 179.75 180.25

Cal 1-6 deg. 180 179.75 180.25

Difference between angles 4

Cal 1-3 deg. 240 239.75 240.25

Cal 1-3 deg. 240 239.75 240.25

Difference between angles 5

Cal 1-5 deg. 300 299.75 300.25

Cal 1-5 deg. 300 299.75 300.25

Injection quantity adjustment

Rack position

(11.9)

Vist

V

2.06

2.06

2.06

Pump speed

r/min

650

650

650

Average injection quantity

mm3/st.

105.5

104.5

106.5

Max. variation between cylinders

%

0

-4

4

Basic

*

Injection quantity adjustment_02

Rack position

(8.8)

Vist

V

2.5

2.4

2.6

Pump speed

r/min

325

325

325

Average injection quantity

mm3/st.

15

14

16

Max. variation between cylinders

%

0

-10

10

Governor adjustment

Pump speed

r/min

720--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Governor adjustment_02

Pump speed

r/min

670

Advance angle

deg.

0.3

Governor adjustment_03

Pump speed

r/min

(720)

Advance angle

deg.

1.5

1.2

1.8

Governor adjustment_04

Pump speed

r/min

-

Advance angle

deg.

1.5

1.2

1.8

Remarks

Measure the actual speed.

Measure the actual speed.

Governor adjustment_05

Pump speed

r/min

1050

Advance angle

deg.

7

6.7

7.3

Remarks

Finish

Finish

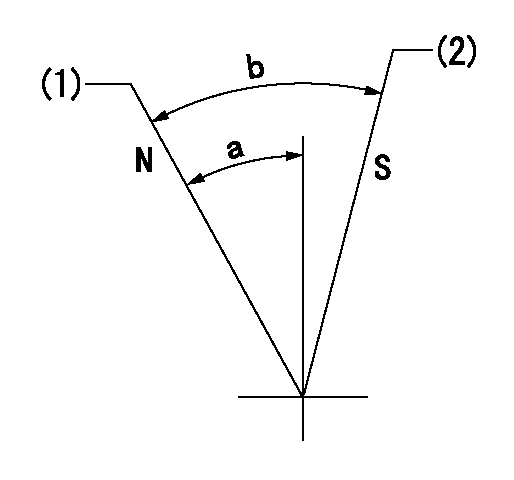

Test data Ex:

Speed control lever angle

N:Pump normal

S:Stop the pump.

(1)Rack position = aa

(2)Rack position bb

----------

aa=20mm bb=1mm

----------

a=27deg+-5deg b=37deg+-5deg

----------

aa=20mm bb=1mm

----------

a=27deg+-5deg b=37deg+-5deg

0000000901

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(30deg)

----------

----------

a=(30deg)

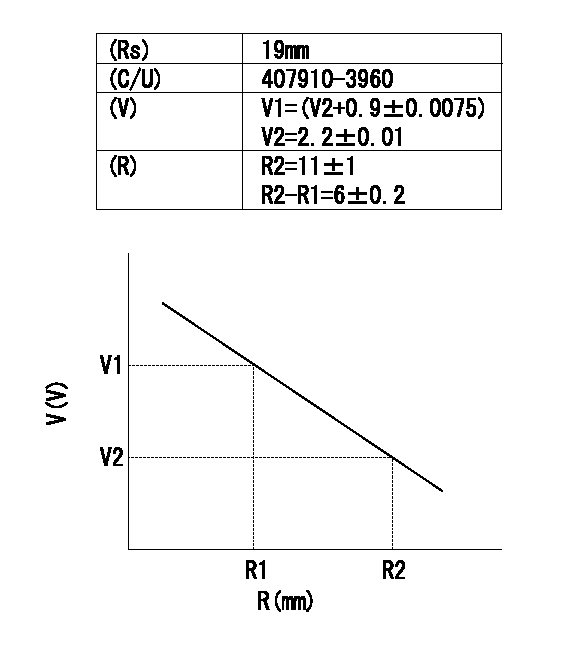

Stop lever angle

(Rs) rack sensor specifications

(C/U) control unit part number

(V) Rack sensor output voltage

(R) Rack position (mm)

1. Confirming governor output characteristics (rack 19 mm, span 6 mm)

(1)When the output voltages of the rack sensor are V1 and V2, check that the rack positions R1 and R2 in the table above are satisfied.

----------

----------

----------

----------

Information:

Start By:a. remove oil pump1. Check the connecting rods and caps for their identification and location. 2. Turn the crankshaft until the connecting rod caps are in the position shown.3. Remove bolts (1) and the and the bearing caps. Remove the lower half of the bearing from the cap.4. Push the connecting rod away from the crankshaft. Remove the upper half of the bearing from the connecting rod. Install the bearings dry when the clearance checks are made. Put clean engine oil on the bearings for final assembly.5. Install the upper half of the bearing in the connecting rod.6. Pull the connecting rod slowly on to the crankshaft.7. Install the lower half of the bearing in the cap. Be sure the tabs in the back of bearings are in the tab grooves of the connecting rod and cap.The serviceman must be very careful to use Plastigage, tool (A) correctly. The following points must be remembered:... Make sure that the backs of the bearings and the bores are clean and dry.... Make sure that the bearing locking tabs are properly seated in their slots.... The crankshaft must be free of oil where the Plastigage touches it.... Put a piece of Plastigage (A) on the crown of the bearing half that is in the cap. Do not allow the Plastigage to extend over the edge of the bearing.... Install the bearing cap using the correct torque-turn specifications. Do not use an impact wrench. Be careful not to dislodge the bearing when the cap is installed.... Do not turn the crankshaft with the Plastigage installed.... Carefully remove the cap but do not remove the Plastigage. Measure the width of the Plastigage while it is in the bearing cap or on the crankshaft journal. Do this by using the correct scale on the package. Record the measurements.... Remove the Plastigage before reinstalling the cap.When using Plastigage, the readings can sometimes be unclear. For example, all parts of the Plastigage are not the same width. Measure the major widths to make sure that they are within the specification range. Also, experience has shown that when checking clearances tighter than 0.10 mm (.004") the readings may be low by 0.013 to 0.025 mm (.0005 to .0010"). Out-of-round journals can give faulty readings. Also, journal taper may be indicated when one end of the Plastigage is wider that the other.For complete details concerning measuring bearing clearances, see Engine Bearings And Crankshafts, Form No. SEBD0531. 8. Use Plastigage (A) to check the bearing clearance.9. Put Plastigage (A) on the bearing.10. Put 2P2506 Thread Lubricant on the threads of the rod bolts. Be sure the cylinder numbers on the rod cap and rod are the same and are on the same side of connecting rod. Numbers are on the same side of the rod and cap as are the bearing tab slots. If new rods are installed, put the cylinder number on the rod and cap. Do not turn the crankshaft when Plastigage (A) is in position.