Information injection-pump assembly

ZEXEL

106671-5220

1066715220

Rating:

Cross reference number

ZEXEL

106671-5220

1066715220

Zexel num

Bosch num

Firm num

Name

106671-5220

INJECTION-PUMP ASSEMBLY

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

132424-0620

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.65

3.6

3.7

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

11.6

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

154.8

152.8

156.8

Max. variation between cylinders

%

0

-4

4

Basic

*

Fixing the lever

*

Boost pressure

kPa

29.3

29.3

Boost pressure

mmHg

220

220

Injection quantity adjustment_02

Adjusting point

C

Rack position

10.4

Pump speed

r/min

300

300

300

Average injection quantity

mm3/st.

117.4

115.4

119.4

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_03

Adjusting point

E

Rack position

7.8+-0.5

Pump speed

r/min

225

225

225

Average injection quantity

mm3/st.

14.3

13.3

15.3

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Boost compensator adjustment

Pump speed

r/min

300

300

300

Rack position

10.4

Boost pressure

kPa

4

2.7

5.3

Boost pressure

mmHg

30

20

40

Boost compensator adjustment_02

Pump speed

r/min

300

300

300

Rack position

12.3+0.2

Boost pressure

kPa

16

16

16

Boost pressure

mmHg

120

120

120

Timer adjustment

Pump speed

r/min

1200--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1150

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

-

Advance angle

deg.

2

2

2

Remarks

Measure the actual speed, stop

Measure the actual speed, stop

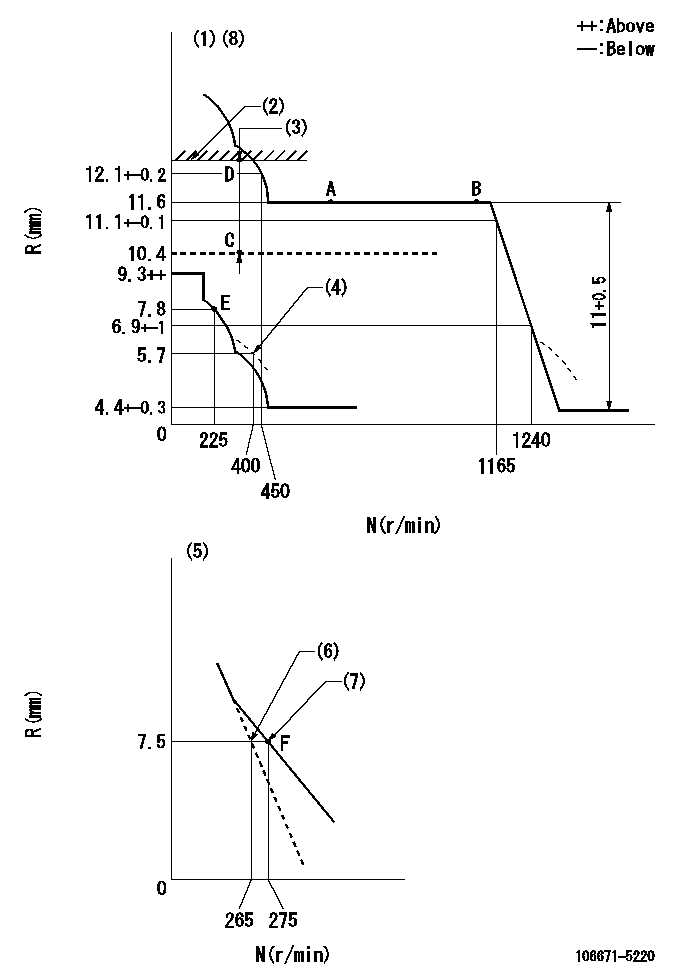

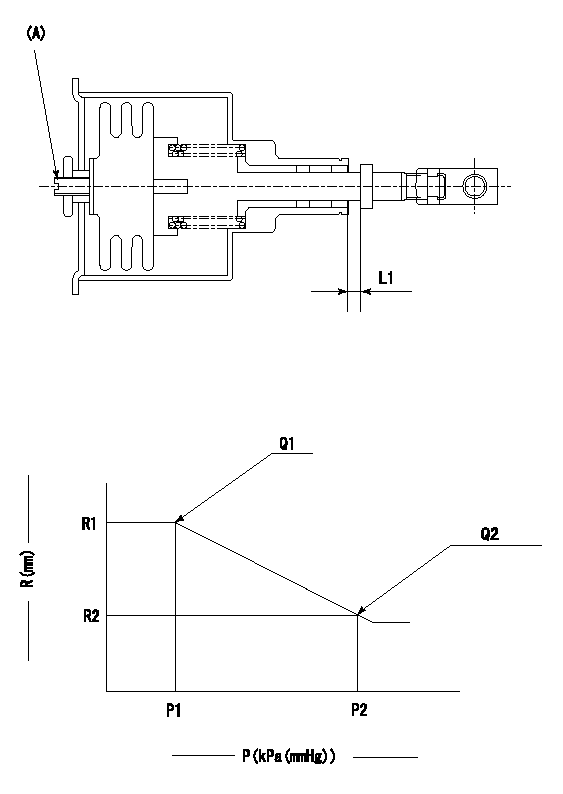

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Tolerance for racks not indicated: +-0.05mm.

(2)Rack limit using the stop lever: R1

(3)Boost compensator stroke: BCL

(4)Damper spring setting

(5)Variable speed specification: idling adjustment

(6)Main spring setting

(7)Set idle sub-spring

(8)Perform governor adjustment at an ambient temperature of at least 15 deg C (boost compensator start spring is shape memory alloy).

----------

R1=12.3+0.2mm BCL=2+-0.1mm

----------

----------

R1=12.3+0.2mm BCL=2+-0.1mm

----------

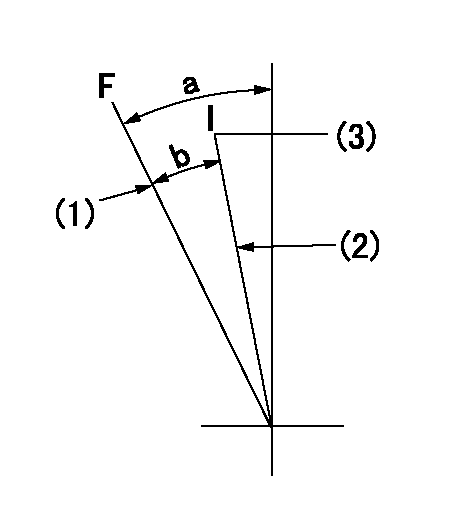

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

(2)Stopper bolt setting

(3)Set the pump speed at aa

----------

aa=275r/min

----------

a=23deg+-5deg b=15deg+-5deg

----------

aa=275r/min

----------

a=23deg+-5deg b=15deg+-5deg

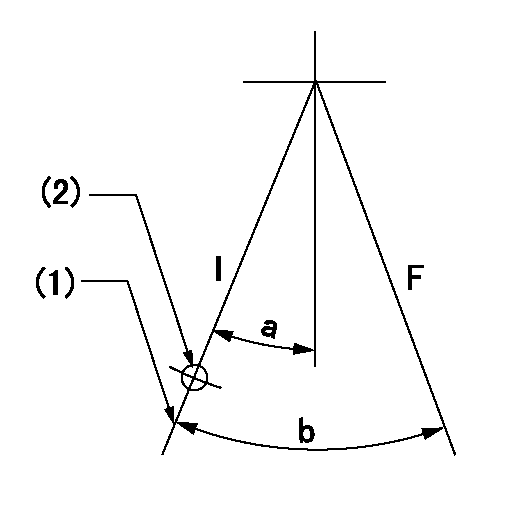

0000000901

F:Full load

I:Idle

(1)Stopper bolt setting

(2)At center of threaded hole above R = aa

----------

aa=17mm

----------

a=15deg+-5deg b=27deg+-3deg

----------

aa=17mm

----------

a=15deg+-5deg b=27deg+-3deg

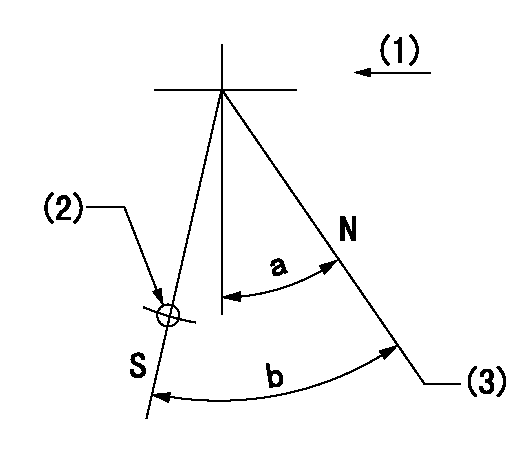

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Drive side

(2)Use the hole at R = aa

(3)Rack position bb

----------

aa=50mm bb=12.3+0.2mm

----------

a=30deg+-5deg b=32deg+-5deg

----------

aa=50mm bb=12.3+0.2mm

----------

a=30deg+-5deg b=32deg+-5deg

0000001501 ACS

(A) Set screw

1. Aneroid compensator unit adjustment

Screw in (A) to obtain L1.

2. Adjustment following governor installation

(1)Set the speed of the pump to N1 r/min and fix the control lever at the full set position.

(2)Screw in the aneroid compensator to obtain the performance shown in the graph above.

----------

N1=1100r/min L1=0.1~0.5mm

----------

R1=11.6mm R2=(9.0)mm P1=90.6+-2.7kPa(680+-20mmHg) P2=57.7+-0.7kPa(433+-5mmHg) Q1=(152.6)+-4cm3/1000st Q2=90.2+-2cm3/1000st

----------

N1=1100r/min L1=0.1~0.5mm

----------

R1=11.6mm R2=(9.0)mm P1=90.6+-2.7kPa(680+-20mmHg) P2=57.7+-0.7kPa(433+-5mmHg) Q1=(152.6)+-4cm3/1000st Q2=90.2+-2cm3/1000st

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(30deg)

----------

----------

a=(30deg)

Information:

Typical Example1. With the rear of wire connector toward you, snap tool (A) (the correct size for the wire being removed) over the wire of the contact to be removed.2. Slide tool (A) along the wire into the contact cavity until it engages the contact and resistance is felt. Do not twist or insert tool (A) at an angle.

Typical Example3. Pull contact (2) and wire assembly out of connector (1).4. Remove the damaged contact from the wire.

Typical Example5. Use tool (B) and the following procedure to secure contact (2) to the wire.a. Strip 6.3 mm (.25 in.) insulation from the wire.b. Raise selector knob (3) and rotate until arrow is aligned with the wire size to be crimped.c. Loosen locknut. Turn adjusting screw (4) in (clockwise) until it stops.

Typical Exampled. Insert contact (2) into tool (B). Turn the adjusting screw out (counter clockwise) until the contact is flush with indentor cover (5) on tool (B). Tighten locknut.

Typical Examplec. Insert wire in contact (2). The contact must be centered between the indentors. Close the handles until the handle contacts the stop.d. Release the handles and remove the crimped contact.e. Inspect the contact to insure that all wire strands are inside the crimp barrel. Look in the hole in the contact. If the crimp is correct wire strands will be visable in the hole in the contact.

Typical Example6. Grasp the wire approximately 25.4 mm (1.00 in.) behind the contact crimp barrel.7. Hold connector (1) with the rear grommet facing you.8. Push contact (2) straight into connector (1) until a positive stop is felt.9. Gently pull on the wire and connector assembly to confirm that the contact is properly locked in place.

Have questions with 106671-5220?

Group cross 106671-5220 ZEXEL

Nissan-Diesel

Nissan-Diesel

106671-5220

INJECTION-PUMP ASSEMBLY