Information injection-pump assembly

BOSCH

9 400 616 834

9400616834

ZEXEL

106671-4930

1066714930

Rating:

Service parts 106671-4930 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

21.6{220}

15.

NOZZLE SET

Include in #1:

106671-4930

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 400 616 834

9400616834

ZEXEL

106671-4930

1066714930

Zexel num

Bosch num

Firm num

Name

106671-4930

9 400 616 834

HYUNDAI

INJECTION-PUMP ASSEMBLY

6D22T * K

6D22T * K

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131424-4620

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

4.8

4.75

4.85

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

10

Pump speed

r/min

950

950

950

Average injection quantity

mm3/st.

104.6

101.6

107.6

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

C

Rack position

5.7+-0.5

Pump speed

r/min

285

285

285

Average injection quantity

mm3/st.

12.6

10

15.2

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Injection quantity adjustment_03

Adjusting point

D

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

133

113

153

Fixing the lever

*

Rack limit

*

Timer adjustment

Pump speed

r/min

650--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

600

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

950

Advance angle

deg.

2

1.5

2.5

Remarks

Finish

Finish

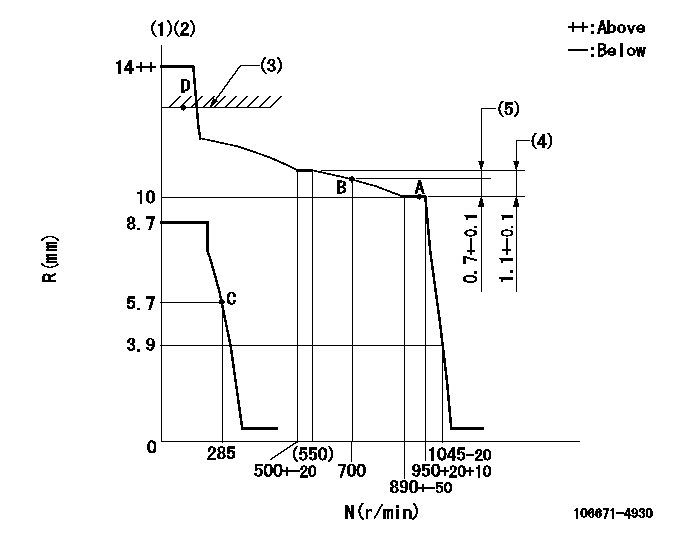

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Supplied with torque spring not set.

(3)RACK LIMIT

(4)Rack difference between N = N1 and N = N2

(5)Rack difference to N = N3

----------

K=15 N1=950r/min N2=520r/min N3=950r/min

----------

----------

K=15 N1=950r/min N2=520r/min N3=950r/min

----------

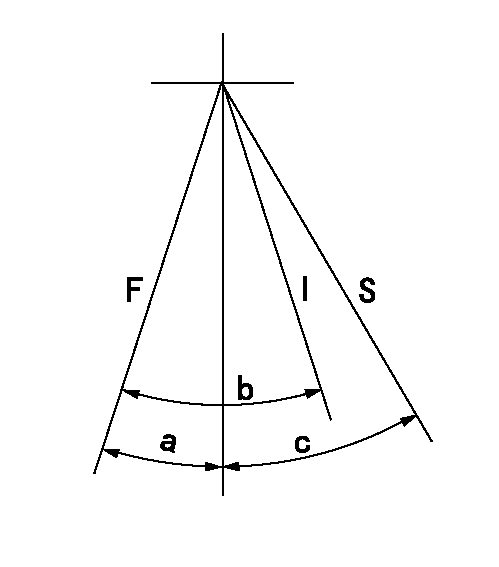

Speed control lever angle

F:Full speed

I:Idle

S:Stop

----------

----------

a=4deg+-5deg b=30deg+-5deg c=35deg+-3deg

----------

----------

a=4deg+-5deg b=30deg+-5deg c=35deg+-3deg

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=19deg+-5deg b=53deg+-5deg

----------

----------

a=19deg+-5deg b=53deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=16deg

----------

a=(7deg)

----------

aa=16deg

----------

a=(7deg)

Information:

1. Drain the coolant from the radiator. 2. Remove bolts (1) and grill (2). 3. Remove bolts (5) and fan guard (3). Remove bolts (6) and support bracket (4). Remove the enclosure group top panel (7).4. Remove the bolts holding the enclosure group side panels. Remove the side panels.5. Loosen the hose clamps on the upper and lower radiator hoses. Disconnect the radiator hoses from the radiator. 6. Use tooling (A) and attach a hoist to radiator (8). Remove the lower bolts holding the radiator to the base. Remove radiator (8). The weight of the radiator is 73 kg (161 lb.). The following steps are for the installation of the radiator.7. Use a hoist to install the radiator on the base. Install the bolts. Remove the hoist and tooling (A) from the radiator.8. Connect the upper and lower radiator hoses to the radiator. Tighten the hose clamps.9. Install the enclosure group side panels.10. Install the enclosure group top panel. Install the grill and the fan guard.11. Fill the radiator with coolant to the correct level. See the Maintenance Manual.Remove And Install Radiator And Radiator Guard (Prime)

1. Drain the coolant from the radiator. 2. Loosen hose clamps (4) and (5). Disconnect tube (1) from hose (6). Rotate tube (1) 180° for clearance. Remove bolts (2) from support arms (3). 3. Remove eight bolts (7) holding fan guard (8) to the radiator guard. 4. Install tool (A) and a hoist to the radiator. 5. Remove four bolts (10) that fasten the lower radiator elbow to the radiator. Separate the elbow from the radiator. Remove bolt (11) from the crankcase vent hose clamp.Remove four mounting bolts (9). Remove the radiator and radiator guard. The weight of the radiator and radiator guard is 250 Kg (550 lb.). The following steps are for the installation of the radiator and radiator guard.6. Use a hoist to put the radiator and radiator guard in position on the base. Install four mounting bolts (9). Remove the hoist and tool (A).7. Install the gasket and lower radiator elbow (12) to the radiator. Install bolts (10). Install bolt (11) and the clamp to hold the crankcase vent hose in place.8. Install bolts (7) to hold fan guard (8) in position.9. Connect tube (1) to hose (6) and tighten hose clamps (4) and (5). Install bolts (2) to secure control arms (3) to the radiator guard.10. Fill the radiator with coolant to the correct level. See the Maintenance Manual.Disassemble And Assemble Radiator

Start By:a. remove radiator and radiator guard **The radiator can be disassembled and assembled without removing the radiator and guard. 1. Remove eighteen bolts (2) and remove four plates (4). Remove four bolts, block off plate (1) and the gasket. Remove four bolts, upper radiator hose adapter (3) and the gasket. 2. Loosen four bolts (7). Disconnect tube assemblies (5) and (8). Remove four bolts (9) and remove coolant level switch if applicable. 3. Remove eleven bolts (11) and remove overflow tube (10), crankcase vent tube clamp (13)

1. Drain the coolant from the radiator. 2. Loosen hose clamps (4) and (5). Disconnect tube (1) from hose (6). Rotate tube (1) 180° for clearance. Remove bolts (2) from support arms (3). 3. Remove eight bolts (7) holding fan guard (8) to the radiator guard. 4. Install tool (A) and a hoist to the radiator. 5. Remove four bolts (10) that fasten the lower radiator elbow to the radiator. Separate the elbow from the radiator. Remove bolt (11) from the crankcase vent hose clamp.Remove four mounting bolts (9). Remove the radiator and radiator guard. The weight of the radiator and radiator guard is 250 Kg (550 lb.). The following steps are for the installation of the radiator and radiator guard.6. Use a hoist to put the radiator and radiator guard in position on the base. Install four mounting bolts (9). Remove the hoist and tool (A).7. Install the gasket and lower radiator elbow (12) to the radiator. Install bolts (10). Install bolt (11) and the clamp to hold the crankcase vent hose in place.8. Install bolts (7) to hold fan guard (8) in position.9. Connect tube (1) to hose (6) and tighten hose clamps (4) and (5). Install bolts (2) to secure control arms (3) to the radiator guard.10. Fill the radiator with coolant to the correct level. See the Maintenance Manual.Disassemble And Assemble Radiator

Start By:a. remove radiator and radiator guard **The radiator can be disassembled and assembled without removing the radiator and guard. 1. Remove eighteen bolts (2) and remove four plates (4). Remove four bolts, block off plate (1) and the gasket. Remove four bolts, upper radiator hose adapter (3) and the gasket. 2. Loosen four bolts (7). Disconnect tube assemblies (5) and (8). Remove four bolts (9) and remove coolant level switch if applicable. 3. Remove eleven bolts (11) and remove overflow tube (10), crankcase vent tube clamp (13)

Have questions with 106671-4930?

Group cross 106671-4930 ZEXEL

Niigata-Urawa

Hyundai

106671-4930

9 400 616 834

INJECTION-PUMP ASSEMBLY

6D22T

6D22T