Information injection-pump assembly

ZEXEL

106671-4630

1066714630

Rating:

Service parts 106671-4630 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

25.5{260}

15.

NOZZLE SET

Include in #1:

106671-4630

as INJECTION-PUMP ASSEMBLY

Cross reference number

ZEXEL

106671-4630

1066714630

Zexel num

Bosch num

Firm num

Name

106671-4630

INJECTION-PUMP ASSEMBLY

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8130

Bosch type code

EFEP215A

Nozzle

105780-0050

Bosch type code

DN6TD119NP1T

Nozzle holder

105780-2090

Bosch type code

EFEP215

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131425-0120

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.9

3.85

3.95

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

15.9

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

354

349

359

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

5.9+-0.5

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

62

59

65

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

290

280

300

Fixing the lever

*

Rack limit

*

Timer adjustment

Pump speed

r/min

-

Advance angle

deg.

0

0

0

Remarks

Measure speed (beginning of operation).

Measure speed (beginning of operation).

Timer adjustment_02

Pump speed

r/min

-

Advance angle

deg.

4.5

4.5

4.5

Remarks

Measure the actual speed, stop

Measure the actual speed, stop

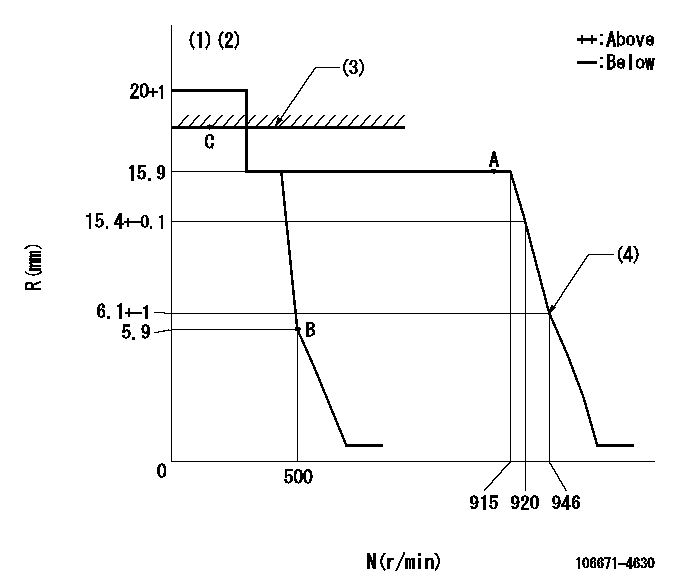

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

(4)Idle sub spring setting: L1.

----------

K=4 L1=6.1-0.5mm

----------

----------

K=4 L1=6.1-0.5mm

----------

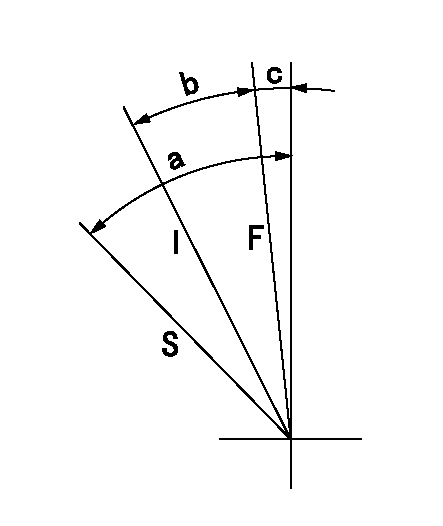

Speed control lever angle

F:Full speed

I:Idle

S:Stop

----------

----------

a=52deg+-3deg b=23deg+-5deg c=14deg+-5deg

----------

----------

a=52deg+-3deg b=23deg+-5deg c=14deg+-5deg

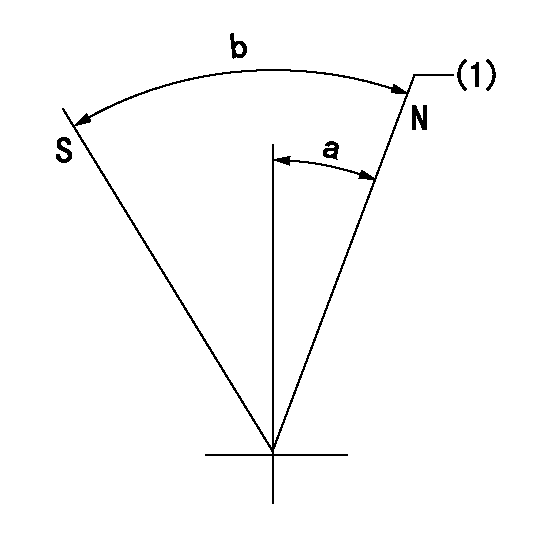

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Normal

----------

----------

a=36deg+-5deg b=53deg+-5deg

----------

----------

a=36deg+-5deg b=53deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position for the No. 6 cylinder's beginning of injection

(3)B.T.D.C.: aa

(4)-

----------

aa=16deg

----------

a=(10deg)

----------

aa=16deg

----------

a=(10deg)

Information:

Stopping the engine immediately after it has been working under load can result in overheating and accelerated wear of the engine components. Allow the engine to cool down before stopping. Avoiding hot engine shutdowns will maximize turbocharger shaft and bearing life.

Emergency Stopping

Emergency shutoff controls are for EMERGENCY use ONLY. DO NOT use Emergency shutoff devices or controls for normal stopping procedure.

Make sure that any external system components that have been operating to support engine operation are secured after any stop.Emergency Stop Buttons

Emergency Stop Button, shown mounted on a junction box.Emergency stops may be made by pushing the Emergency Stop Button located on the junction box (if equipped). Both the Button and the air inlet shutoff (if equipped) require resetting before the engine will start.Manual Stopping

A manual shutoff shaft is provided to override the governor control. The shaft will move the fuel control linkage to the FUEL OFF position. Refer to the Model Views for the engine location of the shaft. The engine may be stopped by using the shaft and the Woodward Actuator (if equipped) or the Mechanical Governor (if equipped).

Typical Woodward Actuator Control Lever.If equipped with a Woodward Actuator, move the control lever to the FUEL OFF position.

Typical Mechanical Governor ControlIf equipped with a Mechanical Governor Control, move the control to the FUEL OFF position.Hold the lever at the FUEL OFF position until the engine stops.Air Shutoff (If Equipped)

Some engines are equipped with an air shutoff, located between the aftercooler and the turbocharger. If equipped with an air shutoff lever, move the lever to the OFF position.Manual Stop Procedure

There may be several ways to shut off your engine. Make sure the shutoff procedures are understood. Use the following general guidelines for stopping the engine.1. Disengage any driven equipment or remove the load from engine.2. Allow the engine to run at rated speed for five minutes.3. Run the engine at 1/2 rated speed for two to three minutes.4. Reduce the engine speed to low idle for 30 seconds.Check the crankcase oil level during the engine idle. Read the LOW IDLE side of the dipstick. Maintain the oil level between the ADD and FULL marks.5. Shut the engine off by turning the start/stop switch to the stop or off position.After Stopping the Engine

* Check the crankcase oil level. Maintain the oil level between the ADD and FULL marks in the FULL RANGE zone on the dipstick.* Repair any leaks, perform minor adjustments, tighten loose bolts, etc.* Note the service hour meter reading. Perform periodic maintenance as instructed in the Maintenance Schedule.* Fill the fuel tank to prevent accumulation of moisture in the fuel. Do not overfill.

Only use antifreeze/coolant mixtures recommended in the Cooling System Specifications of this manual. Failure to do so can cause engine damage.

* Allow the radiator and engine jacket water system to cool. Check the coolant level. Maintain the cooling system to 13 mm (1/2 inch) from bottom of the fill pipe.If freezing temperatures are expected, check the coolant for proper antifreeze protection. The cooling system

Have questions with 106671-4630?

Group cross 106671-4630 ZEXEL

106671-4630

INJECTION-PUMP ASSEMBLY