Information injection-pump assembly

ZEXEL

106671-4610

1066714610

Rating:

Service parts 106671-4610 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

10.

NOZZLE AND HOLDER ASSY

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

13.

NOZZLE-HOLDER

14.

NOZZLE

15.

NOZZLE SET

Include in #1:

106671-4610

as INJECTION-PUMP ASSEMBLY

Cross reference number

ZEXEL

106671-4610

1066714610

Zexel num

Bosch num

Firm num

Name

106671-4610

INJECTION-PUMP ASSEMBLY

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

132424-0620

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

4.1

4.05

4.15

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

12.5

Pump speed

r/min

1175

1175

1175

Each cylinder's injection qty

mm3/st.

209

202.7

215.3

Basic

*

Fixing the lever

*

Boost pressure

kPa

30.7

30.7

Boost pressure

mmHg

230

230

Injection quantity adjustment_02

Adjusting point

B

Rack position

5.5+-0.5

Pump speed

r/min

225

225

225

Each cylinder's injection qty

mm3/st.

10.4

9.4

11.4

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_03

Adjusting point

C

Rack position

13.2+-0.

5

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

188

188

218

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Remarks

Boost compensatory excess lever at excess.

Boost compensatory excess lever at excess.

Boost compensator adjustment

Pump speed

r/min

500

500

500

Rack position

10.1

Boost pressure

kPa

6.7

4

9.4

Boost pressure

mmHg

50

30

70

Boost compensator adjustment_02

Pump speed

r/min

500

500

500

Rack position

(12.5)

Boost pressure

kPa

17.3

17.3

17.3

Boost pressure

mmHg

130

130

130

Timer adjustment

Pump speed

r/min

-

Advance angle

deg.

0

0

0

Remarks

Measure speed (beginning of operation).

Measure speed (beginning of operation).

Timer adjustment_02

Pump speed

r/min

-

Advance angle

deg.

1

1

1

Remarks

Measure the actual speed, stop

Measure the actual speed, stop

Test data Ex:

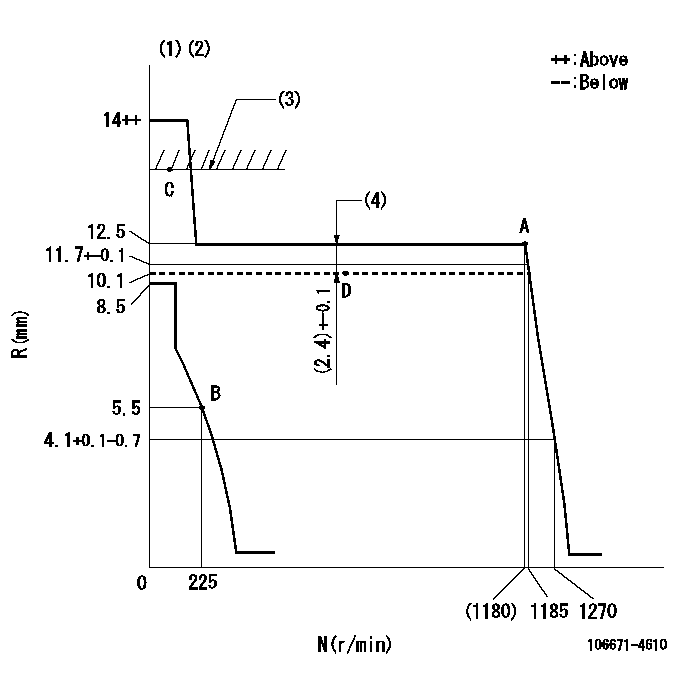

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)Boost compensator excessive fuel lever at operation: L1 (at 0 boost pressure)

(4)Boost compensator stroke

----------

K=5 L1=(13.2)mm

----------

----------

K=5 L1=(13.2)mm

----------

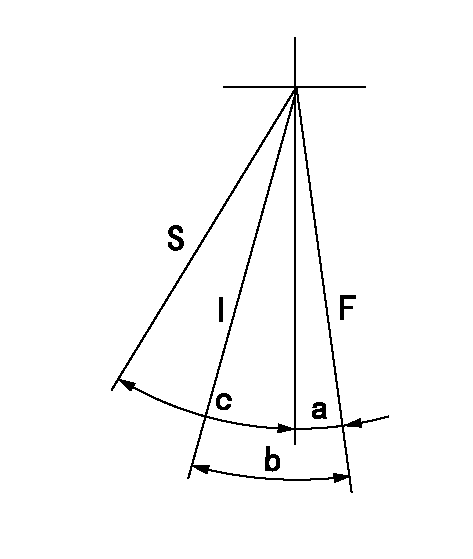

Speed control lever angle

F:Full speed

I:Idle

S:Stop

----------

----------

a=10deg+-5deg b=35deg+-5deg c=32deg+-3deg

----------

----------

a=10deg+-5deg b=35deg+-5deg c=32deg+-3deg

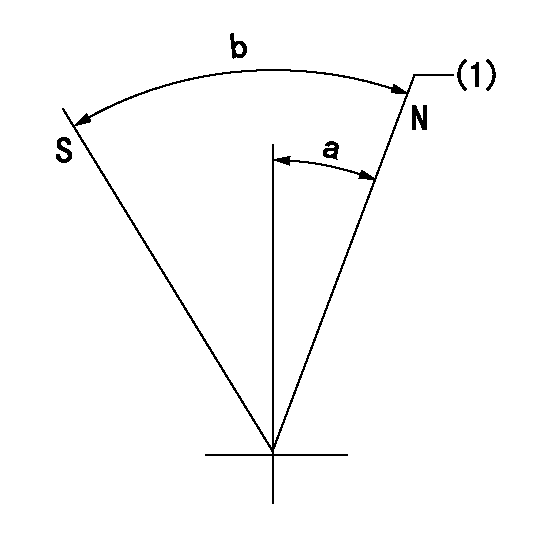

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Normal

----------

----------

a=20deg+-5deg b=53deg+-5deg

----------

----------

a=20deg+-5deg b=53deg+-5deg

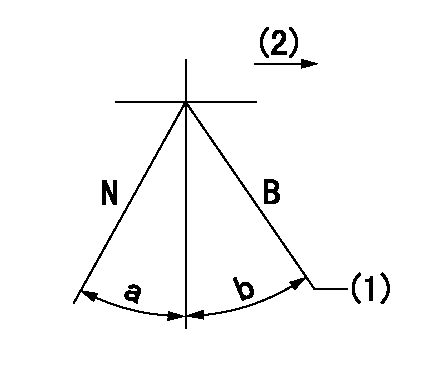

0000001101

N:Normal

B:When boosted

(1)Rack position = aa at boost pressure 0.

(2)Drive side

----------

aa=(13.2)mm

----------

a=(15deg) b=(15deg)

----------

aa=(13.2)mm

----------

a=(15deg) b=(15deg)

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(60deg)

----------

----------

a=(60deg)

Information:

Commercial Diesel Engine Oils

The performance of commercial diesel engine oils are based on API categories. These API categories are developed to provide commercial lubricants for a wide variety of diesel engines that operate at various conditions.If Caterpillar DEO (multi-grade) is not used, the following commercial oils are recommended.* API CG-4 Preferred* API CF-4 AllowedAPI CG-4 oils are preferred for Caterpillar engines because of the fuel sulfur level. API CG-4 is the only oil category that evaluates oils with engine tests utilizing 0.05 percent sulfur fuel.The following explanations of these API categories can be used to make the proper choice of a commercial oil. CG-4: This is the newest oil category. CG-4 oils were primarily developed for diesel engines that are operating on 0.05 percent sulfur diesel fuel. All of the laboratory engine tests for this category were run with 0.05 percent sulfur diesel fuel. This category also defines oils that have superior soot discrepancy. CG-4 oils will provide improved viscosity control and improved crankcase cleanliness in applications where oil soot is a problem. CG-4 oils will provide improved viscosity control and improved crankcase cleanliness in applications where oil soot is a problem. CG-4 oils should also be used in engines that contain hydraulically actuated fuel injection pumps; these are the first oils to pass industry tests for foam control and viscosity shear loss. CG-4 oils must also pass recently developed tests for metals corrosion, and wear. CG-4 oils can be used in all Caterpillar engines where CF-4 oils are recommended. CF-4 oils service a wide variety of modern diesel engines. This oil classification was developed with 0.40 percent sulfur diesel fuel. The fuel used in the CF-4 tests represents the type of diesel fuels commonly available world wide. CF-4 oils provide improved piston deposit control and improved oil control when compared to the CE category oils. CF-4 oils also provide improved soot dispersancy compared to CD or CF category oils.Some commercial oils meeting these API specifications may require shortened oil change intervals as determined by close monitoring of oil condition and wear metals (Caterpillar S*O*S Oil Analysis Program preferred).Consult with your Caterpillar dealer for the latest oil recommendations or refer to the following Caterpillar Supplements: SEBU6250, SEBU6251, and SEBU6385.

Failure to follow these oil recommendations can cause shortened engine life due to deposits and or excessive wear.

Total Base Number (TBN) and Fuel Sulfur Levels For Caterpillar Direct Injection (DI) Diesel Engines

The TBN for a new oil is dependent on the sulfur level of the fuel used. For direct injection engines running distillate diesel fuel, the minimum new oil TBN (by ASTM D 2896) must be 10 times the fuel sulfur level, and the minimum TBN is 5 regardless of sulfur level, see the chart below.TBN vs Fuel Sulfur for Caterpillar DI Diesel Engines

Y=oil TBN shown by ASTM D2896. X=percent of fuel sulfur by weight. New oil TBN (1). Change oil when the used oil TBN limit (2) is reached.In areas where the fuel sulfur exceeds 1.5 percent, choose an

The performance of commercial diesel engine oils are based on API categories. These API categories are developed to provide commercial lubricants for a wide variety of diesel engines that operate at various conditions.If Caterpillar DEO (multi-grade) is not used, the following commercial oils are recommended.* API CG-4 Preferred* API CF-4 AllowedAPI CG-4 oils are preferred for Caterpillar engines because of the fuel sulfur level. API CG-4 is the only oil category that evaluates oils with engine tests utilizing 0.05 percent sulfur fuel.The following explanations of these API categories can be used to make the proper choice of a commercial oil. CG-4: This is the newest oil category. CG-4 oils were primarily developed for diesel engines that are operating on 0.05 percent sulfur diesel fuel. All of the laboratory engine tests for this category were run with 0.05 percent sulfur diesel fuel. This category also defines oils that have superior soot discrepancy. CG-4 oils will provide improved viscosity control and improved crankcase cleanliness in applications where oil soot is a problem. CG-4 oils will provide improved viscosity control and improved crankcase cleanliness in applications where oil soot is a problem. CG-4 oils should also be used in engines that contain hydraulically actuated fuel injection pumps; these are the first oils to pass industry tests for foam control and viscosity shear loss. CG-4 oils must also pass recently developed tests for metals corrosion, and wear. CG-4 oils can be used in all Caterpillar engines where CF-4 oils are recommended. CF-4 oils service a wide variety of modern diesel engines. This oil classification was developed with 0.40 percent sulfur diesel fuel. The fuel used in the CF-4 tests represents the type of diesel fuels commonly available world wide. CF-4 oils provide improved piston deposit control and improved oil control when compared to the CE category oils. CF-4 oils also provide improved soot dispersancy compared to CD or CF category oils.Some commercial oils meeting these API specifications may require shortened oil change intervals as determined by close monitoring of oil condition and wear metals (Caterpillar S*O*S Oil Analysis Program preferred).Consult with your Caterpillar dealer for the latest oil recommendations or refer to the following Caterpillar Supplements: SEBU6250, SEBU6251, and SEBU6385.

Failure to follow these oil recommendations can cause shortened engine life due to deposits and or excessive wear.

Total Base Number (TBN) and Fuel Sulfur Levels For Caterpillar Direct Injection (DI) Diesel Engines

The TBN for a new oil is dependent on the sulfur level of the fuel used. For direct injection engines running distillate diesel fuel, the minimum new oil TBN (by ASTM D 2896) must be 10 times the fuel sulfur level, and the minimum TBN is 5 regardless of sulfur level, see the chart below.TBN vs Fuel Sulfur for Caterpillar DI Diesel Engines

Y=oil TBN shown by ASTM D2896. X=percent of fuel sulfur by weight. New oil TBN (1). Change oil when the used oil TBN limit (2) is reached.In areas where the fuel sulfur exceeds 1.5 percent, choose an

Have questions with 106671-4610?

Group cross 106671-4610 ZEXEL

Niigata-Urawa

106671-4610

INJECTION-PUMP ASSEMBLY