Information injection-pump assembly

BOSCH

9 400 616 803

9400616803

ZEXEL

106671-4346

1066714346

NIIGATA-URAWA

W1N47110G

w1n47110g

Rating:

Service parts 106671-4346 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

31.4{320}

15.

NOZZLE SET

Include in #1:

106671-4346

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 400 616 803

9400616803

ZEXEL

106671-4346

1066714346

NIIGATA-URAWA

W1N47110G

w1n47110g

Zexel num

Bosch num

Firm num

Name

9 400 616 803

W1N47110G NIIGATA-URAWA

INJECTION-PUMP ASSEMBLY

DMF13HS K 14CA INJECTION PUMP ASSY PE6P,6PD PE

DMF13HS K 14CA INJECTION PUMP ASSY PE6P,6PD PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8250

Bosch type code

1 688 901 101

Nozzle

105780-0120

Bosch type code

1 688 901 990

Nozzle holder

105780-2190

Opening pressure

MPa

20.7

Opening pressure

kgf/cm2

211

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131424-8921

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

255

255

255

Tester oil delivery pressure

kgf/cm2

2.6

2.6

2.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.05

3

3.1

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

11.3

Pump speed

r/min

900

900

900

Average injection quantity

mm3/st.

148.5

145.5

151.5

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

Z

Rack position

3.7+-0.5

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

34.5

31.5

37.5

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

210

210

220

Fixing the lever

*

Rack limit

*

Timer adjustment

Pump speed

r/min

400--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

350

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

600

Advance angle

deg.

2

1.5

2.5

Timer adjustment_04

Pump speed

r/min

800

Advance angle

deg.

5

4.5

5.5

Remarks

Finish

Finish

Test data Ex:

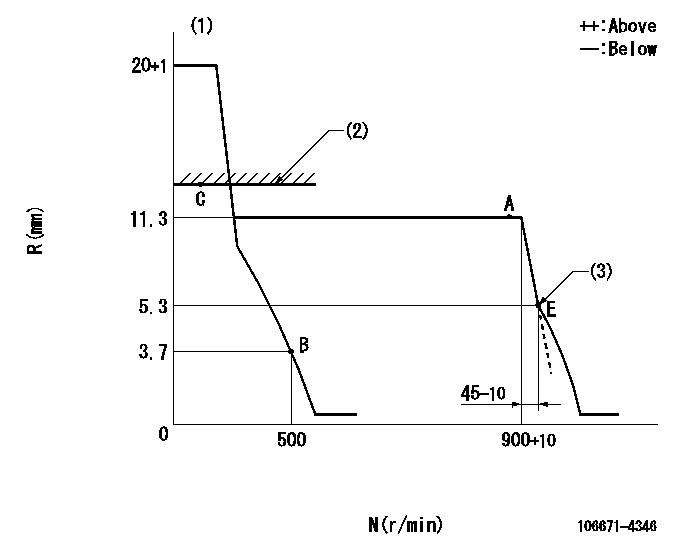

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)RACK LIMIT

(3)Idle sub spring setting: L1.

----------

K=14 L1=5.3-0.5mm

----------

----------

K=14 L1=5.3-0.5mm

----------

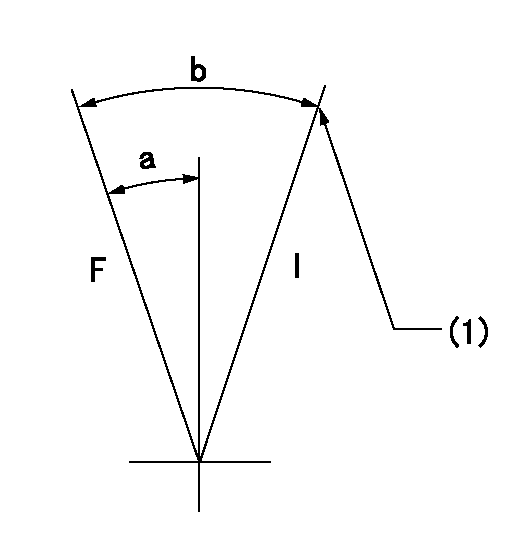

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=19deg+-5deg b=25deg+-5deg

----------

----------

a=19deg+-5deg b=25deg+-5deg

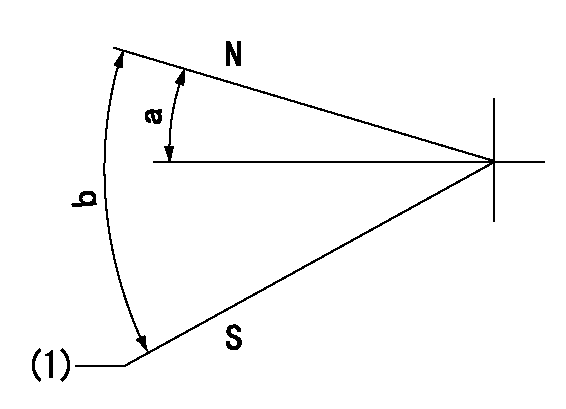

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)At delivery

----------

----------

a=30.5deg+-5deg b=53deg+-5deg

----------

----------

a=30.5deg+-5deg b=53deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(6deg)

----------

----------

a=(6deg)

Information:

Oil Consumption as an Overhaul Indicator

When an engine's oil consumption has risen to three times the initial (new) consumption rate due to normal wear, then the engine should be scheduled for overhaul. There may be a corresponding increase in blowby and a slight increase in fuel consumption.Overhaul Before Failure

A planned Overhaul Before Failure may be your best value, because you can:* Avoid costly unplanned downtime.* Reuse as many original parts as standards permit.* Extend your engine's service life without the risk of a major catastrophe had you continued to operate to failure.* Get the best cost/value relationship per hour of extended life.After Failure Overhaul

If you experience a major engine failure which requires removal of the engine from the hull, there are also many After Failure Overhaul options available. An overhaul should be performed if your block or crankshaft needs to be repaired.If the block and/or crankshaft is repairable, overhaul cost should be between 40 and 50 percent of the cost of a new engine (with like exchange core).This lower cost can be attributed to Caterpillar "designed-in" features, Caterpillar dealer and Caterpillar Remanufactured exchange components.Overhaul Recommendation

To minimize downtime and provide you with the lowest cost and highest value, Caterpillar recommends that the engine be overhauled before failure by scheduling an overhaul with your Caterpillar dealer. Overhaul programs vary with engine application and from dealer to dealer. Therefore, Caterpillar recommends that you confer with your dealer to obtain specific information regarding the types of programs offered and overhaul services provided for extending the life of your engine.If you elect to perform an overhaul without Caterpillar dealer overhaul service, you should be aware of the maintenance that follows.Inspect/Rebuild or Exchange

Cylinder Head Assembly, Cylinder Packs, Cylinder Liners, Connecting Rods, Pistons, Turbocharger, Oil Pump, Spacer Plates, Fuel Ratio Control, Cam Followers, Fuel Transfer Pump, and Timing Advance.These components should be inspected according to the instructions found in various Caterpillar reusability publications. The Index of Publications on Reusability or Salvage of Used Parts, SEBF8029, lists reusability publications needed for inspecting parts.If the parts comply with established inspection specifications expressed in the reusable parts guideline, the parts should be reused.If the parts are not within specification, the parts should be salvaged, repaired, or replaced. Failure to salvage, repair, or replace out-of-spec parts can result in unscheduled downtime, costly repairs, and damage to other engine parts.In addition, using out-of-spec parts can reduce the engine's efficiency and increase fuel consumption. Reduced engine efficiency and increased fuel consumption translates into higher operating costs. Therefore, Caterpillar recommends salvage, repair, or replacement of out-of-spec parts.Install New

Piston Rings, Valve Rotators, Main Bearings, Rod Bearings, Crankshaft Bearings, and Crankshaft Seals.The thrust, main, and rod bearings, valve rotators, and crankshaft seals will probably not last until the second overhaul. Caterpillar recommends the installation of new parts at each overhaul period.Inspect/Replace

Crankshaft, Camshaft, Camshaft Followers and Bearings, Crankshaft Vibration Damper, Governor, Fuel Pump Camshaft, Fuel Racks, Gear Train Gears and Bushings, and Driven Unit Alignment.The ideal time for inspecting these items is while the engine

When an engine's oil consumption has risen to three times the initial (new) consumption rate due to normal wear, then the engine should be scheduled for overhaul. There may be a corresponding increase in blowby and a slight increase in fuel consumption.Overhaul Before Failure

A planned Overhaul Before Failure may be your best value, because you can:* Avoid costly unplanned downtime.* Reuse as many original parts as standards permit.* Extend your engine's service life without the risk of a major catastrophe had you continued to operate to failure.* Get the best cost/value relationship per hour of extended life.After Failure Overhaul

If you experience a major engine failure which requires removal of the engine from the hull, there are also many After Failure Overhaul options available. An overhaul should be performed if your block or crankshaft needs to be repaired.If the block and/or crankshaft is repairable, overhaul cost should be between 40 and 50 percent of the cost of a new engine (with like exchange core).This lower cost can be attributed to Caterpillar "designed-in" features, Caterpillar dealer and Caterpillar Remanufactured exchange components.Overhaul Recommendation

To minimize downtime and provide you with the lowest cost and highest value, Caterpillar recommends that the engine be overhauled before failure by scheduling an overhaul with your Caterpillar dealer. Overhaul programs vary with engine application and from dealer to dealer. Therefore, Caterpillar recommends that you confer with your dealer to obtain specific information regarding the types of programs offered and overhaul services provided for extending the life of your engine.If you elect to perform an overhaul without Caterpillar dealer overhaul service, you should be aware of the maintenance that follows.Inspect/Rebuild or Exchange

Cylinder Head Assembly, Cylinder Packs, Cylinder Liners, Connecting Rods, Pistons, Turbocharger, Oil Pump, Spacer Plates, Fuel Ratio Control, Cam Followers, Fuel Transfer Pump, and Timing Advance.These components should be inspected according to the instructions found in various Caterpillar reusability publications. The Index of Publications on Reusability or Salvage of Used Parts, SEBF8029, lists reusability publications needed for inspecting parts.If the parts comply with established inspection specifications expressed in the reusable parts guideline, the parts should be reused.If the parts are not within specification, the parts should be salvaged, repaired, or replaced. Failure to salvage, repair, or replace out-of-spec parts can result in unscheduled downtime, costly repairs, and damage to other engine parts.In addition, using out-of-spec parts can reduce the engine's efficiency and increase fuel consumption. Reduced engine efficiency and increased fuel consumption translates into higher operating costs. Therefore, Caterpillar recommends salvage, repair, or replacement of out-of-spec parts.Install New

Piston Rings, Valve Rotators, Main Bearings, Rod Bearings, Crankshaft Bearings, and Crankshaft Seals.The thrust, main, and rod bearings, valve rotators, and crankshaft seals will probably not last until the second overhaul. Caterpillar recommends the installation of new parts at each overhaul period.Inspect/Replace

Crankshaft, Camshaft, Camshaft Followers and Bearings, Crankshaft Vibration Damper, Governor, Fuel Pump Camshaft, Fuel Racks, Gear Train Gears and Bushings, and Driven Unit Alignment.The ideal time for inspecting these items is while the engine