Information injection-pump assembly

BOSCH

F 019 Z10 520

f019z10520

ZEXEL

106671-4324

1066714324

Rating:

Service parts 106671-4324 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

10.

NOZZLE AND HOLDER ASSY

11.

Nozzle and Holder

12.

Open Pre:MPa(Kqf/cm2)

13.

NOZZLE-HOLDER

14.

NOZZLE

15.

NOZZLE SET

Include in #1:

106671-4324

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

F 019 Z10 520

f019z10520

ZEXEL

106671-4324

1066714324

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131424-4420

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

4.7

4.65

4.75

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

10.4

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

148

146

150

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Boost pressure

kPa

56

56

Boost pressure

mmHg

420

420

Injection quantity adjustment_02

Adjusting point

B

Rack position

11

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

154.5

151.5

157.5

Max. variation between cylinders

%

0

-3

3

Fixing the lever

*

Boost pressure

kPa

56

56

Boost pressure

mmHg

420

420

Injection quantity adjustment_03

Adjusting point

H

Rack position

5.2+-0.5

Pump speed

r/min

250

250

250

Average injection quantity

mm3/st.

14.5

13

16

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_04

Adjusting point

I

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

165

160

170

Fixing the lever

*

Boost pressure

kPa

56

56

Boost pressure

mmHg

420

420

Rack limit

*

Boost compensator adjustment

Pump speed

r/min

500

500

500

Rack position

8.7

Boost pressure

kPa

22.7

20.7

24.7

Boost pressure

mmHg

170

155

185

Boost compensator adjustment_02

Pump speed

r/min

500

500

500

Rack position

10.4

Boost pressure

kPa

42.7

42.7

42.7

Boost pressure

mmHg

320

320

320

Timer adjustment

Pump speed

r/min

750--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

700

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1100

Advance angle

deg.

3

2.5

3.5

Remarks

Finish

Finish

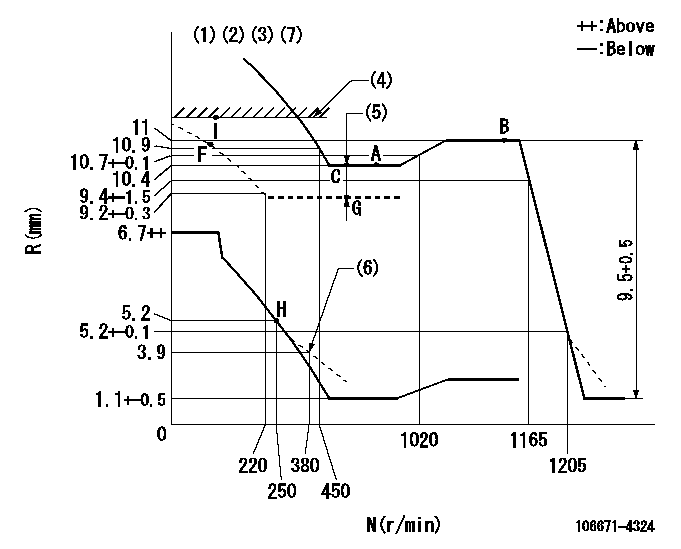

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Lever ratio: RT

(2)Target shim dimension: TH

(3)Tolerance for racks not indicated: +-0.05mm.

(4)RACK LIMIT

(5)Boost compensator stroke: BCL

(6)Damper spring setting

(7)Microswitch adjustment unnecessary.

----------

RT=1 TH=2.9mm BCL=1.7+-0.1mm

----------

----------

RT=1 TH=2.9mm BCL=1.7+-0.1mm

----------

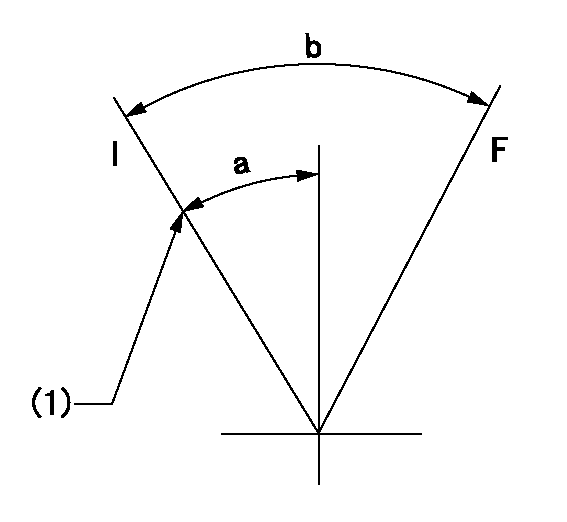

Speed control lever angle

F:Full speed

----------

----------

a=7deg+-5deg

----------

----------

a=7deg+-5deg

0000000901

F:Full load

I:Idle

(1)Stopper bolt setting

----------

----------

a=10deg+-5deg b=34deg+-3deg

----------

----------

a=10deg+-5deg b=34deg+-3deg

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=40deg+-5deg b=73deg+-5deg

----------

----------

a=40deg+-5deg b=73deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position for the No. 6 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(70deg)

----------

----------

a=(70deg)

Information:

Distillate Diesel Fuel

Diesel fuels that meet the specifications in the chart below will provide rated engine performance and full component service life. In North America, diesel fuel identified as No. 1-D and No.2-D in ASTM D975 generally meet these specifications. This chart is for diesel fuels that are distilled from crude oil. Diesel fuels from other sources could exhibit detrimental properties that are not defined or controlled by this specification.. There are many other diesel fuel specifications published by governments and technical societies. Those diesel fuel specifications usually do not contain all of the parameters addressed by Caterpillar in this specification. To assure optimum engine performance, a complete fuel analysis should be obtained prior to engine operation. The fuel analysis should include all of the properties listed in the Distillate Fuel Recommendations chart. If a particular fuel does not meet the minimum Caterpillar requirements, the engine could exhibit excessive fuel system wear, fuel system failure, or excessive engine wear caused by deposits or corrosion.0.05 Percent Sulfur Diesel Fuel

In the U.S.A., 0.05 percent sulfur diesel fuel has been used in all on-highway diesel truck engines since January 1, 1994. This low sulfur fuel was mandated as a means of directly reducing particulate emissions from diesel truck engines. This low sulfur fuel will also be used in Caterpillar commercial diesel engines where low emissions are required and where supply sources provide this type of fuel. Caterpillar has not seen any detrimental effects with 0.05 percent sulfur fuel in Caterpillar commercial diesel engines.

Heavy Fuel Oil (HFO), Residual fuel, or Blended fuel must NOT be used in Caterpillar diesel engines (except in certain 3600 Series HFO engines). Severe component wear and component failures will result if HFO type fuels are used.

Diesel fuels that meet the specifications in the chart below will provide rated engine performance and full component service life. In North America, diesel fuel identified as No. 1-D and No.2-D in ASTM D975 generally meet these specifications. This chart is for diesel fuels that are distilled from crude oil. Diesel fuels from other sources could exhibit detrimental properties that are not defined or controlled by this specification.. There are many other diesel fuel specifications published by governments and technical societies. Those diesel fuel specifications usually do not contain all of the parameters addressed by Caterpillar in this specification. To assure optimum engine performance, a complete fuel analysis should be obtained prior to engine operation. The fuel analysis should include all of the properties listed in the Distillate Fuel Recommendations chart. If a particular fuel does not meet the minimum Caterpillar requirements, the engine could exhibit excessive fuel system wear, fuel system failure, or excessive engine wear caused by deposits or corrosion.0.05 Percent Sulfur Diesel Fuel

In the U.S.A., 0.05 percent sulfur diesel fuel has been used in all on-highway diesel truck engines since January 1, 1994. This low sulfur fuel was mandated as a means of directly reducing particulate emissions from diesel truck engines. This low sulfur fuel will also be used in Caterpillar commercial diesel engines where low emissions are required and where supply sources provide this type of fuel. Caterpillar has not seen any detrimental effects with 0.05 percent sulfur fuel in Caterpillar commercial diesel engines.

Heavy Fuel Oil (HFO), Residual fuel, or Blended fuel must NOT be used in Caterpillar diesel engines (except in certain 3600 Series HFO engines). Severe component wear and component failures will result if HFO type fuels are used.