Information injection-pump assembly

ZEXEL

106671-4321

1066714321

Rating:

Cross reference number

ZEXEL

106671-4321

1066714321

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

4.7

4.65

4.75

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

10.3

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

145

143

147

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Boost pressure

kPa

46.7

46.7

Boost pressure

mmHg

350

350

Injection quantity adjustment_02

Adjusting point

B

Rack position

11.3

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

161

158

164

Max. variation between cylinders

%

0

-3

3

Fixing the lever

*

Boost pressure

kPa

46.7

46.7

Boost pressure

mmHg

350

350

Injection quantity adjustment_03

Adjusting point

H

Rack position

5.2+-0.5

Pump speed

r/min

250

250

250

Average injection quantity

mm3/st.

14.5

13

16

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_04

Adjusting point

I

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

165

160

170

Fixing the lever

*

Remarks

Set the excess lever.

Set the excess lever.

Boost compensator adjustment

Pump speed

r/min

600

600

600

Rack position

8.2

Boost pressure

kPa

14.7

12.7

16.7

Boost pressure

mmHg

110

95

125

Boost compensator adjustment_02

Pump speed

r/min

600

600

600

Rack position

10.3

Boost pressure

kPa

33.3

33.3

33.3

Boost pressure

mmHg

250

250

250

Timer adjustment

Pump speed

r/min

750--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

700

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1100

Advance angle

deg.

3

2.5

3.5

Remarks

Finish

Finish

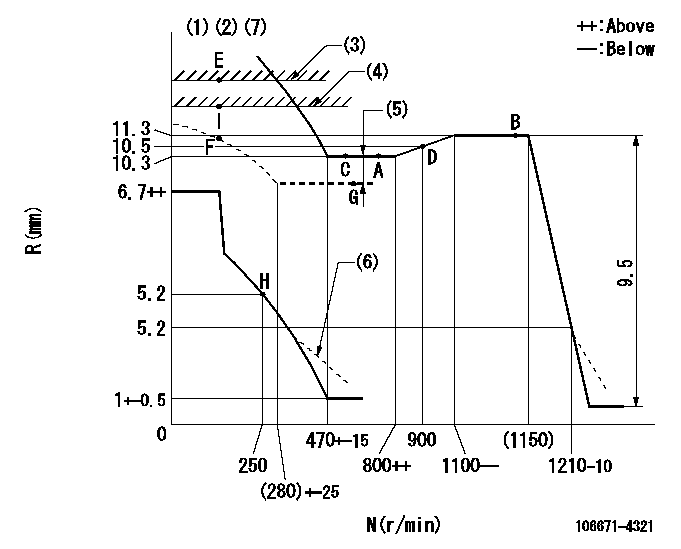

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Lever ratio: RT

(2)Target shim dimension: TH

(3)RACK LIMIT: RAL

(4)Excess fuel lever setting

(5)Boost compensator stroke: BCL

(6)Damper spring setting: DL

(7)Microswitch adjustment unnecessary.

----------

RT=1 TH=3mm RAL=13+-0.1mm BCL=2.1+-0.1mm DL=4.9-0.2mm

----------

----------

RT=1 TH=3mm RAL=13+-0.1mm BCL=2.1+-0.1mm DL=4.9-0.2mm

----------

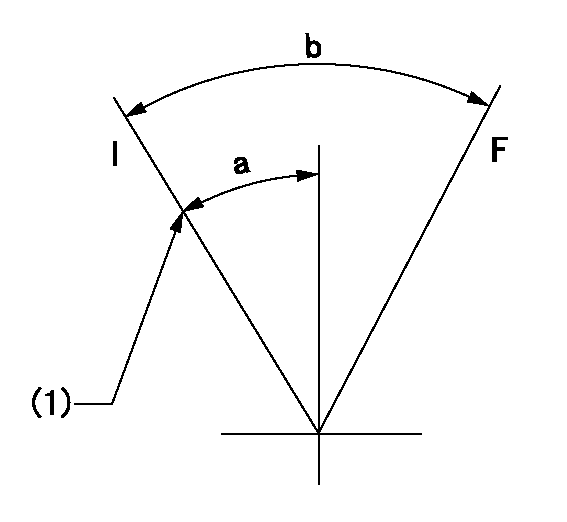

Speed control lever angle

F:Full speed

----------

----------

a=7deg+-5deg

----------

----------

a=7deg+-5deg

0000000901

F:Full load

I:Idle

(1)Stopper bolt setting

----------

----------

a=10deg+-5deg b=34deg+-3deg

----------

----------

a=10deg+-5deg b=34deg+-3deg

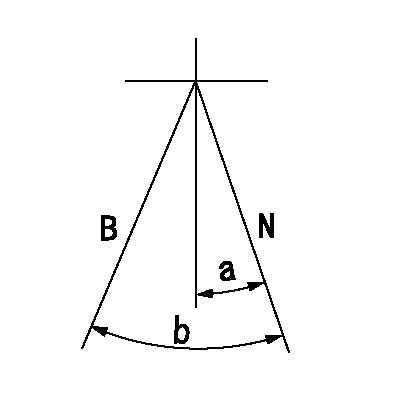

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=40deg+-5deg b=73deg+-5deg

----------

----------

a=40deg+-5deg b=73deg+-5deg

0000001101

N:Normal

B:When boosted

----------

----------

a=(6deg) b=(25deg)

----------

----------

a=(6deg) b=(25deg)

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position for the No. 6 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(70deg)

----------

----------

a=(70deg)

Information:

If the vessel cannot continue under its own power, it is recommended that the vessel be towed. The propeller of a vessel being towed will windmill through the water. Propeller rotation causes the propeller shaft to rotate. An extended period of propeller shaft rotation without proper lubrication will damage the marine transmission shaft bearings. If pressurized oil cannot be supplied to the marine transmission shaft bearings during towing, the propeller shaft must be secured to prevent propeller shaft rotation.

Most marine transmissions can be back driven (propeller wind milling with dead engine) under the following conditions, provided that vessel speed does not exceed normal maximum propulsion speed of the vessel. For intermittent back driving, such as:* Sailboat auxiliary (short trips)* Towing purse boats in seining operations1. Start the engine and operate the marine gear in neutral, at normal oil pressure, for a minimum of five minutes. Do this once every 24 hours.2. Maintain the marine transmission oil level the same for back driving as for normal propulsion, or keep level above FULL mark on dipstick.3. Make sure the marine transmission is in neutral while the craft is being towed. For continuous back driving, such as:* Sailboat auxiliary (long trips)* Towing to deliver a boat* Towing home a boat with engine trouble (long trip-more than a day)1. Operate in neutral with oil at normal oil pressure for a minimum of five minutes every 12 hours.2. Fill the marine gear with oil until the oil level touches the input shaft on the engine centerline.3. Make sure the marine transmission is in neutral while the craft is being towed.Securing the Propeller

Reverse wind milling can cause engine damage. The best way to prevent reverse wind milling is to secure the propeller. If possible, lock the propeller shaft to prevent rotation.After the propeller shaft has been secured, have the towing vessel travel at slow speed in order to minimize the wind milling force on the propeller. If the vessel is being towed and the marine transmission is allowed to windmill for long periods, the engine must be started and the marine transmission operated for five minutes every 12 hours to lubricate the propeller shaft bearings.There are several ways of preventing propeller shaft rotation. The correct method depends upon the turning force of the propeller, and the construction of the propeller shaft tunnel. Use the method best suited for the type of installation.Propeller Shaft Wrapping

1. On small vessels, wrap a heavy rope around the propeller shaft. The number of wraps needed will depend upon the mass of the propeller and propeller shaft.2. Secure the rope in the opposite direction of propeller shaft rotation.Securing the Companion Flange

1. Remove one or more bolts from the companion flange coupling. Bolt a chain to the companion flange. Wrap the chain several times around the propeller shaft.2. Secure the loose end of the chain at a right angle to the propeller shaft and in the opposite direction of propeller shaft rotation.