Information injection-pump assembly

ZEXEL

106671-4320

1066714320

Rating:

Cross reference number

ZEXEL

106671-4320

1066714320

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

4.7

4.65

4.75

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

10.3

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

145

143

147

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Boost pressure

kPa

46.7

46.7

Boost pressure

mmHg

350

350

Injection quantity adjustment_02

Adjusting point

B

Rack position

11.2

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

161

158

164

Max. variation between cylinders

%

0

-3

3

Fixing the lever

*

Boost pressure

kPa

46.7

46.7

Boost pressure

mmHg

350

350

Injection quantity adjustment_03

Adjusting point

H

Rack position

5.2+-0.5

Pump speed

r/min

250

250

250

Average injection quantity

mm3/st.

14.5

13

16

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Boost compensator adjustment

Pump speed

r/min

600

600

600

Rack position

8.2

Boost pressure

kPa

14.7

12.7

16.7

Boost pressure

mmHg

110

95

125

Boost compensator adjustment_02

Pump speed

r/min

600

600

600

Rack position

10.3

Boost pressure

kPa

33.3

33.3

33.3

Boost pressure

mmHg

250

250

250

Timer adjustment

Pump speed

r/min

750--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

700

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1100

Advance angle

deg.

3

2.5

3.5

Remarks

Finish

Finish

Test data Ex:

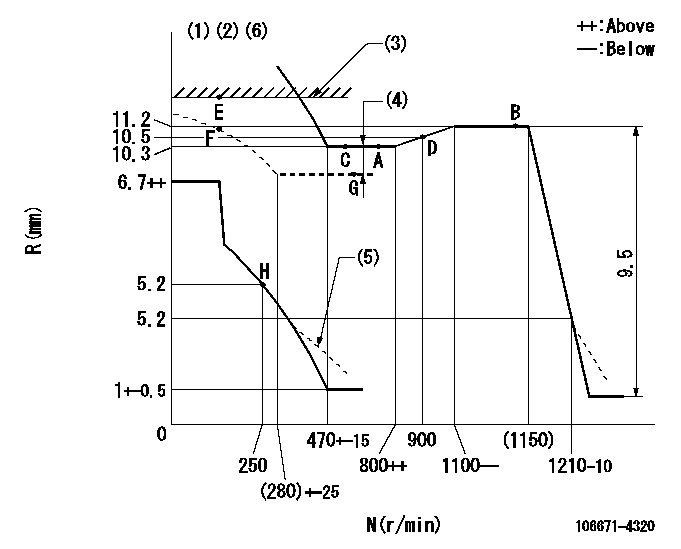

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Lever ratio: RT

(2)Target shim dimension: TH

(3)RACK LIMIT: RAL

(4)Boost compensator stroke: BCL

(5)Damper spring setting: DL

(6)Microswitch adjustment unnecessary.

----------

RT=1 TH=3mm RAL=11.9+-0.1mm BCL=2.1+-0.1mm DL=4.9-0.2mm

----------

----------

RT=1 TH=3mm RAL=11.9+-0.1mm BCL=2.1+-0.1mm DL=4.9-0.2mm

----------

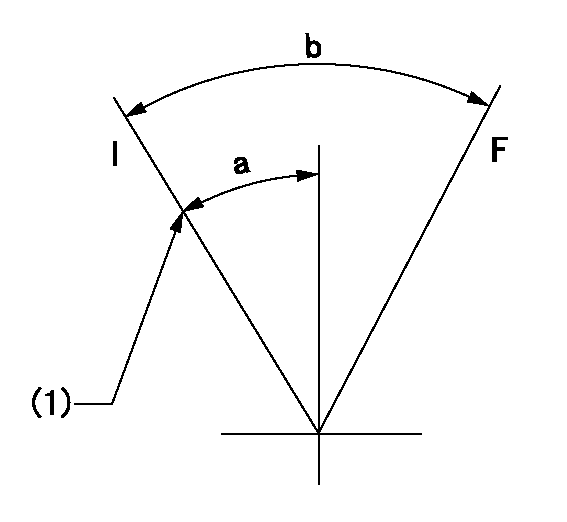

Speed control lever angle

F:Full speed

----------

----------

a=7deg+-5deg

----------

----------

a=7deg+-5deg

0000000901

F:Full load

I:Idle

(1)Stopper bolt setting

----------

----------

a=10deg+-5deg b=34deg+-3deg

----------

----------

a=10deg+-5deg b=34deg+-3deg

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=40deg+-5deg b=73deg+-5deg

----------

----------

a=40deg+-5deg b=73deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position for the No. 6 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(70deg)

----------

----------

a=(70deg)

Information:

Caterpillar Diesel Engines can operate effectively in cold weather. However, engine operation in cold weather is dependent on the type of fuel used and how well the fuel moves through fuel related components. The purpose of this section is to explain some of the problems and steps that can be taken to minimize fuel problems during cold weather operation [below 5°C (40°F)].Fuel and the Effect from Cold Weather

The two types of diesel fuel available for your engine are typically grades No. 1 and No.2. No.2 diesel fuel is the most commonly used fuel. No. 1 diesel fuel, or a blend of No. 1 and No.2, is best suited for cold weather operation.Quantities of No. 1 diesel fuel are limited, and generally only available during the winter months in the colder climates. During cold weather operation, if No. 1 fuel is unavailable, it may be necessary to use No.2 diesel fuel.There are three major differences between No. 1 and No.2 diesel fuel. No. 1 diesel fuel has:* a lower cloud point* a lower pour point* a lower BTU (kJ) (heat content) rating per unit volume of fuel than the average No.2 diesel fuel.When using No. 1 diesel fuel, you may notice a drop in power and fuel efficiency. You should not experience any other operating effects.The cloud point is the temperature at which a cloud or haze of wax crystals begins to form in the fuel and cause fuel filters to plug. The pour point is the temperature which diesel fuel begins to thicken and be more resistant to flow through fuel pumps and lines.Be aware of these fuel values when purchasing your diesel fuel. Anticipate the average outside (ambient) temperature for the area your engine will be operating. Engines fueled in one climate may not operate satisfactorily if moved to another because of problems that result from cold weather.Before troubleshooting for low power or poor performance in winter months, check the type of fuel being used.When No.2 diesel fuel is used: starting aids, engine oil pan heaters, engine coolant heaters, fuel heaters, and fuel line insulation also provide a means of minimizing starting and fuel problems in cold weather.Fuel Related Components in Cold Weather

Fuel Tanks

Condensation can form in partially filled fuel tanks. Top off fuel tanks before leaving overnight.Fuel tanks should contain some provision for draining water and sediment from the bottom of the tanks. Some fuel tanks use supply pipes that allow water and sediment to settle below the end of the fuel supply pipe.Some fuel tanks use supply lines that take fuel directly from the bottom of the tank. If equipped with this system, regular maintenance of the fuel system filter(s) is important.Check the fuel level in the day tank daily by observing the sight gauge. Drain the water and sediment from any fuel storage tank weekly, at the oil change period, and before the fuel tank is refilled. This will help prevent water and/or sediment from being pumped from the fuel storage tank into the

The two types of diesel fuel available for your engine are typically grades No. 1 and No.2. No.2 diesel fuel is the most commonly used fuel. No. 1 diesel fuel, or a blend of No. 1 and No.2, is best suited for cold weather operation.Quantities of No. 1 diesel fuel are limited, and generally only available during the winter months in the colder climates. During cold weather operation, if No. 1 fuel is unavailable, it may be necessary to use No.2 diesel fuel.There are three major differences between No. 1 and No.2 diesel fuel. No. 1 diesel fuel has:* a lower cloud point* a lower pour point* a lower BTU (kJ) (heat content) rating per unit volume of fuel than the average No.2 diesel fuel.When using No. 1 diesel fuel, you may notice a drop in power and fuel efficiency. You should not experience any other operating effects.The cloud point is the temperature at which a cloud or haze of wax crystals begins to form in the fuel and cause fuel filters to plug. The pour point is the temperature which diesel fuel begins to thicken and be more resistant to flow through fuel pumps and lines.Be aware of these fuel values when purchasing your diesel fuel. Anticipate the average outside (ambient) temperature for the area your engine will be operating. Engines fueled in one climate may not operate satisfactorily if moved to another because of problems that result from cold weather.Before troubleshooting for low power or poor performance in winter months, check the type of fuel being used.When No.2 diesel fuel is used: starting aids, engine oil pan heaters, engine coolant heaters, fuel heaters, and fuel line insulation also provide a means of minimizing starting and fuel problems in cold weather.Fuel Related Components in Cold Weather

Fuel Tanks

Condensation can form in partially filled fuel tanks. Top off fuel tanks before leaving overnight.Fuel tanks should contain some provision for draining water and sediment from the bottom of the tanks. Some fuel tanks use supply pipes that allow water and sediment to settle below the end of the fuel supply pipe.Some fuel tanks use supply lines that take fuel directly from the bottom of the tank. If equipped with this system, regular maintenance of the fuel system filter(s) is important.Check the fuel level in the day tank daily by observing the sight gauge. Drain the water and sediment from any fuel storage tank weekly, at the oil change period, and before the fuel tank is refilled. This will help prevent water and/or sediment from being pumped from the fuel storage tank into the