Information injection-pump assembly

ZEXEL

106671-4300

1066714300

MITSUBISHI-HEAV

3256562060

3256562060

Rating:

Cross reference number

ZEXEL

106671-4300

1066714300

MITSUBISHI-HEAV

3256562060

3256562060

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8130

Bosch type code

EFEP215A

Nozzle

105780-0050

Bosch type code

DN6TD119NP1T

Nozzle holder

105780-2090

Bosch type code

EFEP215

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3.9

3.85

3.95

Rack position

Point B R=B

Point B R=B

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

11.6

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

306.2

296.2

316.2

Max. variation between cylinders

%

0

-5

5

Fixing the lever

*

Boost pressure

kPa

140

140

Boost pressure

mmHg

1050

1050

Injection quantity adjustment_02

Adjusting point

B

Rack position

12.3

Pump speed

r/min

750

750

750

Average injection quantity

mm3/st.

308.8

299.8

317.8

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the lever

*

Boost pressure

kPa

140

140

Boost pressure

mmHg

1050

1050

Injection quantity adjustment_03

Adjusting point

C

Rack position

5.1+-0.5

Pump speed

r/min

250

250

250

Average injection quantity

mm3/st.

28.5

25.5

31.5

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Remarks

Injection only at cylinders 1, 3, 4 and 6.

Injection only at cylinders 1, 3, 4 and 6.

Injection quantity adjustment_04

Adjusting point

C

Rack position

5.1

Pump speed

r/min

250

250

250

Average injection quantity

mm3/st.

0

0

5

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Remarks

Injection only at cylinders 2 and 5.

Injection only at cylinders 2 and 5.

Boost compensator adjustment

Pump speed

r/min

500

500

500

Rack position

10.9

Boost pressure

kPa

74.6

71.9

77.3

Boost pressure

mmHg

560

540

580

Boost compensator adjustment_02

Pump speed

r/min

500

500

500

Rack position

12.3

Boost pressure

kPa

127

120.3

133.7

Boost pressure

mmHg

950

900

1000

Timer adjustment

Pump speed

r/min

450--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

400

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

700

Advance angle

deg.

1.4

0.9

1.9

Timer adjustment_04

Pump speed

r/min

1050

Advance angle

deg.

4

3.5

4.5

Remarks

Finish

Finish

Test data Ex:

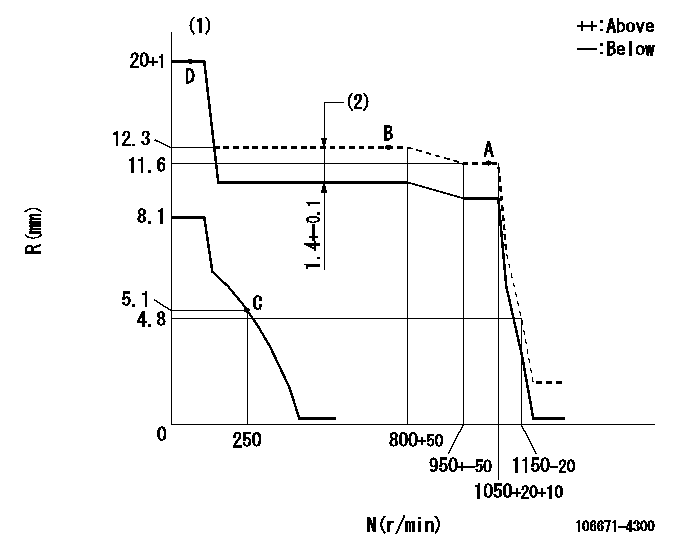

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Boost compensator stroke

----------

K=5

----------

----------

K=5

----------

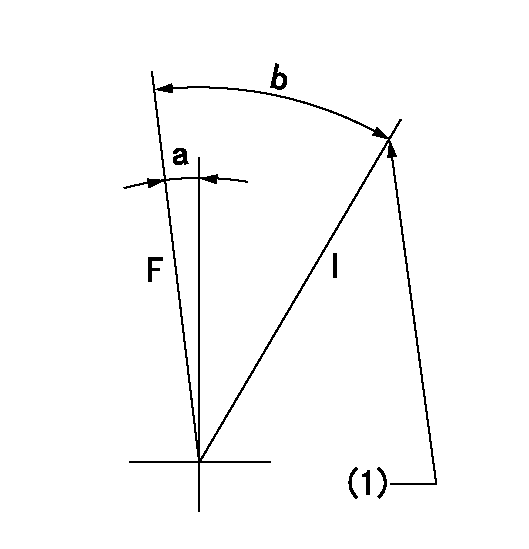

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=1deg+-5deg b=27deg+-5deg

----------

----------

a=1deg+-5deg b=27deg+-5deg

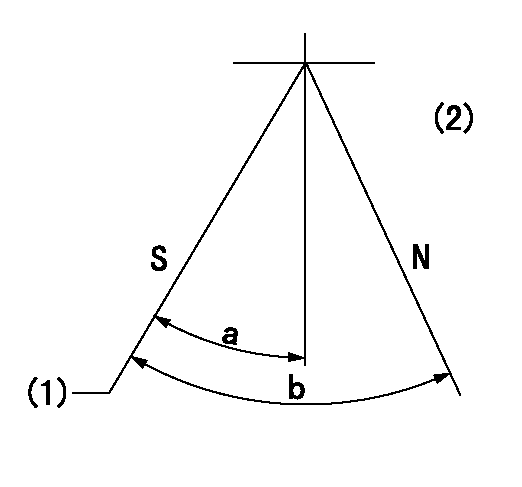

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Pump speed aa, rack position bb

(2)Seal after setting the stopper bolt.

----------

aa=0r/min bb=1-0.2mm

----------

a=35deg+-5deg b=70deg+-5deg

----------

aa=0r/min bb=1-0.2mm

----------

a=35deg+-5deg b=70deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(20deg)

----------

----------

a=(20deg)

Information:

You must read and understand the warnings and instructions contained in the Safety section of this manual before performing any operation or maintenance procedures.Before proceeding with PM Level 3 maintenance, perform all Daily, PM Level 1 and Level 2 maintenance requirements. The following maintenance procedures are to be performed Every 160 000 km (96,000 miles) or 4000 service hours or 4 years under ideal operating conditions, whichever occurs first.Refer to the Maintenance Schedule and Service Factor chart. Apply the correct Service Factor to determine the proper maintenance interval for your vehicle.Air Compressor

Inspect/Rebuild or Exchange

Do not disconnect the air line from the air compressor governor without purging the air brake and auxiliary air systems.Failure to purge the air brake and auxiliary air systems before removing the air compressor and/or air lines could cause personal injury.

Inspect the air compressor as instructed by the truck/vehicle manufacturers' instructions or for more information on how to check your air compressor, refer to the

Inspect/Rebuild or Exchange

Do not disconnect the air line from the air compressor governor without purging the air brake and auxiliary air systems.Failure to purge the air brake and auxiliary air systems before removing the air compressor and/or air lines could cause personal injury.

Inspect the air compressor as instructed by the truck/vehicle manufacturers' instructions or for more information on how to check your air compressor, refer to the