Information injection-pump assembly

BOSCH

9 400 611 138

9400611138

ZEXEL

106671-4020

1066714020

NIIGATA-URAWA

W2B47010B

w2b47010b

Rating:

Cross reference number

BOSCH

9 400 611 138

9400611138

ZEXEL

106671-4020

1066714020

NIIGATA-URAWA

W2B47010B

w2b47010b

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131425-0120

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.9

3.85

3.95

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

13.7

Pump speed

r/min

1000

1000

1000

Average injection quantity

mm3/st.

209.3

204.3

214.3

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

7.1+-0.5

Pump speed

r/min

250

250

250

Average injection quantity

mm3/st.

30

27

33

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Remarks

Adjust only variation between cylinders; adjust governor according to governor specifications.

Adjust only variation between cylinders; adjust governor according to governor specifications.

Timer adjustment

Pump speed

r/min

(300)

Advance angle

deg.

0.5

Timer adjustment_02

Pump speed

r/min

600

Advance angle

deg.

2.5

2

3

Timer adjustment_03

Pump speed

r/min

775

Advance angle

deg.

6

5.5

6.5

Remarks

Finish

Finish

Test data Ex:

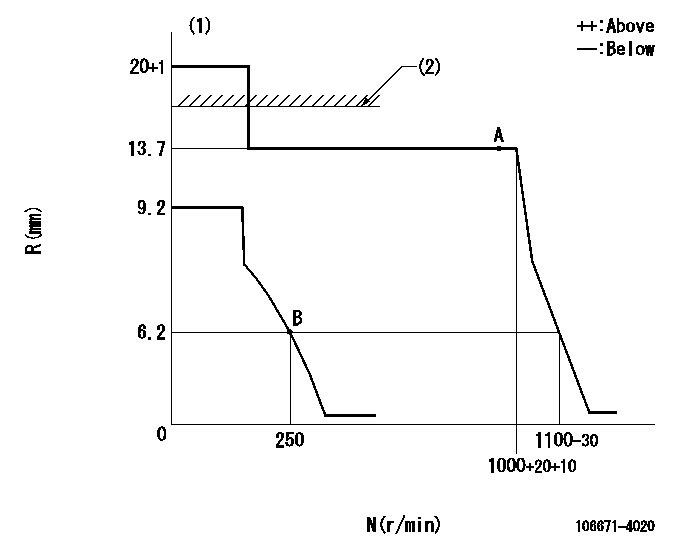

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)RACK LIMIT: RAL

----------

K=20 RAL=16.4+0.2mm

----------

----------

K=20 RAL=16.4+0.2mm

----------

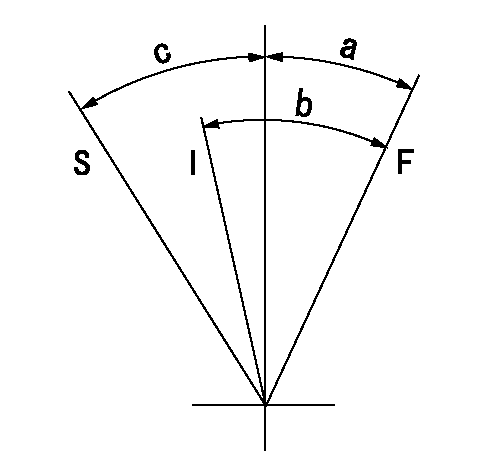

Speed control lever angle

F:Full speed

I:Idle

S:Stop

----------

----------

a=(12deg)+-5deg b=(32deg)+-5deg c=32deg+-3deg

----------

----------

a=(12deg)+-5deg b=(32deg)+-5deg c=32deg+-3deg

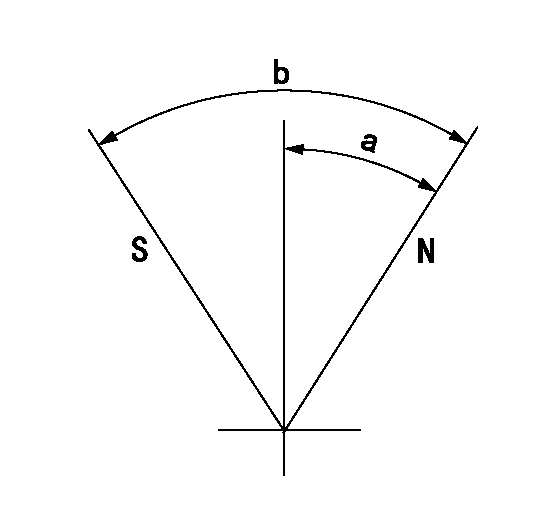

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=42deg+-5deg b=82deg+-5deg

----------

----------

a=42deg+-5deg b=82deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(20deg)

----------

----------

a=(20deg)

Information:

Inspect gaskets before assembly and replace if worn or damaged. 10. Install lip-type seal (1) in housing with tooling (A) [Driver Group (1P0510)]. Install the seal with the lip of the seal away from the thermostat. 11. Install thermostat (2) in the housing as shown. 12. Install the new gaskets in position between the regulator manifold and the thermostat housing. Install thermostat housing (3).13. Refill the cooling system with clean water mixed with a 6 to 10 percent concentration of Caterpillar Cooling System Cleaner. Install radiator filler cap. A 9-12 gallon (33-47 L) cooling system capacity requires one gallon (3.8 L) of Caterpillar Cooling System Cleaner to accommodate the 6-10 percent concentration.Caterpillar Cooling System Cleaner is available through your Caterpillar dealer.14. Start and run the engine to circulate fluid in the cooling system for 90 minutes. Stop the engine, remove radiator filler cap and cooling system drain plugs.15. Drain the cleaning solution. Flush the cooling system with clean water until draining water is clear. Clean and install all drain plugs and/or close the drain valve.

Fill the cooling system with the coolant solution at 5 U.S. gal (20 L) per minute or less to avoid air locks.

See Refill Capacities chart in this publication for the capacity of your engine's system.16. Add coolant to the system to bring it to the proper level by mixing a solution of acceptable water, Caterpillar Antifreeze or equivalent. If NOT using Caterpillar Antifreeze, add supplemental coolant additive, or if equipped with a coolant additive element, install the appropriate element.When NOT using Caterpillar Antifreeze, add 1 U.S. quart (1 L) of Caterpillar Coolant Additive (Conditioner) for every 8 U.S. gal (30 L) of cooling system capacity OR change maintenance element only (if equipped).Refer to the Cooling System Specifications in this publication for all information regarding acceptable water, antifreeze and supplemental coolant additive requirements or contact your Caterpillar dealer for assistance.17. Start and run the engine with the filler cap removed. Allow the coolant to warm, the thermostat to open and the coolant level to stabilize.18. Add coolant mixture if necessary to bring the coolant to within 1/2inch (13 mm) below the bottom of the fill tube or the correct level on the sight glass, if equipped.

In cold weather, frequently check the specific gravity of the coolant solution to ensure adequate protection.If the engine is to be stored in, or shipped to an area with freezing temperatures, the cooling system must be either protected to the lowest expected outside temperature or drained completely to prevent damage.Always check your cooling system before operating your engine.

19. Check the condition of the filler cap gasket. If the gasket is damaged, discard the old filler cap and install

Fill the cooling system with the coolant solution at 5 U.S. gal (20 L) per minute or less to avoid air locks.

See Refill Capacities chart in this publication for the capacity of your engine's system.16. Add coolant to the system to bring it to the proper level by mixing a solution of acceptable water, Caterpillar Antifreeze or equivalent. If NOT using Caterpillar Antifreeze, add supplemental coolant additive, or if equipped with a coolant additive element, install the appropriate element.When NOT using Caterpillar Antifreeze, add 1 U.S. quart (1 L) of Caterpillar Coolant Additive (Conditioner) for every 8 U.S. gal (30 L) of cooling system capacity OR change maintenance element only (if equipped).Refer to the Cooling System Specifications in this publication for all information regarding acceptable water, antifreeze and supplemental coolant additive requirements or contact your Caterpillar dealer for assistance.17. Start and run the engine with the filler cap removed. Allow the coolant to warm, the thermostat to open and the coolant level to stabilize.18. Add coolant mixture if necessary to bring the coolant to within 1/2inch (13 mm) below the bottom of the fill tube or the correct level on the sight glass, if equipped.

In cold weather, frequently check the specific gravity of the coolant solution to ensure adequate protection.If the engine is to be stored in, or shipped to an area with freezing temperatures, the cooling system must be either protected to the lowest expected outside temperature or drained completely to prevent damage.Always check your cooling system before operating your engine.

19. Check the condition of the filler cap gasket. If the gasket is damaged, discard the old filler cap and install