Information injection-pump assembly

ZEXEL

106671-3990

1066713990

HINO

220202860A

220202860a

Rating:

Cross reference number

ZEXEL

106671-3990

1066713990

HINO

220202860A

220202860a

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve (drive side)

134424-2020

Overflow valve opening pressure (drive side)

kPa

162

147

177

Overflow valve opening pressure (drive side)

kgf/cm2

1.65

1.5

1.8

Overflow valve (governor side)

134424-2120

Overflow valve opening pressure (governor side)

kPa

162

147

177

Overflow valve opening pressure (governor side)

kgf/cm2

1.65

1.5

1.8

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.7

3.6

3.7

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

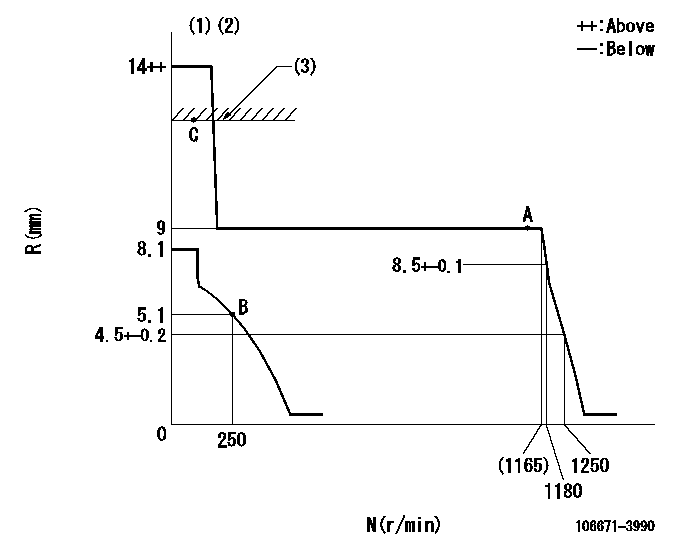

Injection quantity adjustment

Adjusting point

A

Rack position

9

Pump speed

r/min

1160

1160

1160

Average injection quantity

mm3/st.

164

162

166

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

5.1+-0.5

Pump speed

r/min

250

250

250

Average injection quantity

mm3/st.

13

10

16

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

160

155

165

Fixing the lever

*

Rack limit

*

Timer adjustment

Pump speed

r/min

975--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

925

Advance angle

deg.

0.3

Timer adjustment_03

Pump speed

r/min

1150

Advance angle

deg.

2.5

2

3

Remarks

Finish

Finish

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

----------

K=11

----------

----------

K=11

----------

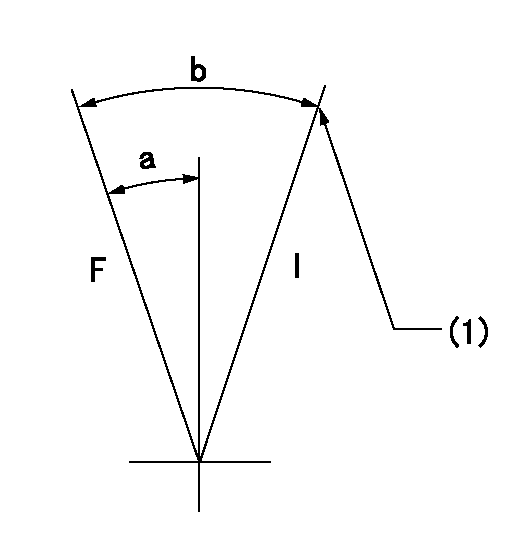

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=10deg+-5deg b=30deg+-5deg

----------

----------

a=10deg+-5deg b=30deg+-5deg

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Normal

----------

----------

a=27deg+-5deg b=53deg+-5deg

----------

----------

a=27deg+-5deg b=53deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(50deg)

----------

----------

a=(50deg)

Information:

Do not exceed 240°F (116°C) maximum engine oil temperature at any time.Do not exceed 2300 rpm in any situation. Overspeeding can result in serious damage to your engine.Operation of the engine over 2300 rpm will cause the Electronic system to activate the CHECK ENGINE lamp, indicating engine overspeed.

No special skills are required to operate a vehicle with a BrakeSaver. However, it requires the operator to observe the engine speed and the BrakeSaver oil temperature.

The BrakeSaver should not be used as a primary or service brake. The BrakeSaver is not an emergency or quick stop brake. Use the service brakes for quick stops.

The BrakeSaver provides auxiliary braking to slow the truck and to control speed on long grades. Governing the deceleration or downhill speed of a vehicle by using the BrakeSaver results in reduced wear on brake linings and brake drums. It helps save the service brakes for emergency stopping requirements.Braking effort is a direct function of engine speed. The greater the engine speed the greater the braking effort. This applies to all engines, especially those with slower speed economy ratings.The BrakeSaver utilizes the engine oil and cooling systems, which eliminates the need for auxiliary oil or cooling systems.Scheduled maintenance on the BrakeSaver, or additional engine maintenance, is not required.Trucks equipped with the BrakeSaver require an additional amount of engine lubricating oil. Refer to the Refill Capacities chart in this publication for proper amount of oil required for a BrakeSaver equipped engine.Manual Control

The hand-operated control lever is usually mounted on the steering column. It provides a smooth modulated application of the BrakeSaver for desired retarding of the vehicle up to 2300 engine rpm.This controlled modulation of the BrakeSaver is especially desirable on slippery roads. Increasing or decreasing the BrakeSaver action is accomplished by moving the control lever. Actuating the manual Brakesaver control will deactivate the Electronic engines' Cruise Control or PTO control.Automatic Control

The mode selector switch must be in the AUTOMATIC MANUAL position and the Electronic system Cruise Control ON/OFF switch must be in the OFF position for automatic control.In this mode, the BrakeSaver will automatically be applied when the clutch is engaged and the accelerator pedal is released.The BrakeSaver will automatically shut off when the clutch is disengaged or when the accelerator pedal is depressed. It will engage again when the clutch is re-engaged and the accelerator pedal is released.Gauges

The BrakeSaver CONTROL AIR PRESSURE gauge indicates the pressure at the BrakeSaver control valve. Air pressure should not exceed 50 psi (345 kPa).If the indicator shows reduced or no pressure, the BrakeSaver may not provide any braking effort. Stop the vehicle or operate at a reduced speed.Control vehicle stopping with proper downshifting and service brakes until proper repairs are made.The BrakeSaver oil temperature gauge indicator should register in the NORMAL (GREEN) range, 240°F (116°C). If the indicator moves to the RED range, move the BrakeSaver manual control lever to the OFF position.Operate the vehicle with the service brakes only, or stop the vehicle and let the engine idle until