Information injection-pump assembly

ZEXEL

106671-3961

1066713961

HINO

220005030A

220005030a

Rating:

Cross reference number

ZEXEL

106671-3961

1066713961

HINO

220005030A

220005030a

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

134424-0920

Overflow valve opening pressure

kPa

162

147

177

Overflow valve opening pressure

kgf/cm2

1.65

1.5

1.8

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.3

3.24

3.3

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.75 60.25

Cal 1-4 deg. 60 59.75 60.25

Difference between angles 2

Cyl.1-2 deg. 120 119.75 120.25

Cyl.1-2 deg. 120 119.75 120.25

Difference between angles 3

Cal 1-6 deg. 180 179.75 180.25

Cal 1-6 deg. 180 179.75 180.25

Difference between angles 4

Cal 1-3 deg. 240 239.75 240.25

Cal 1-3 deg. 240 239.75 240.25

Difference between angles 5

Cal 1-5 deg. 300 299.75 300.25

Cal 1-5 deg. 300 299.75 300.25

Injection quantity adjustment

Adjusting point

A

Rack position

10.1+-0.

5

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

119.5

116.5

122.5

Max. variation between cylinders

%

0

-4

4

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

10.5+-0.

5

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

129.5

127.5

131.5

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Injection quantity adjustment_03

Adjusting point

D

Rack position

11+-0.5

Pump speed

r/min

1150

1150

1150

Average injection quantity

mm3/st.

143

140

146

Max. variation between cylinders

%

0

-4

4

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

E

Rack position

6.6+-0.5

Pump speed

r/min

225

225

225

Average injection quantity

mm3/st.

15

12

18

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Injection quantity adjustment_05

Adjusting point

F

Rack position

11.6+-0.

5

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

126.3

119.3

133.3

Fixing the lever

*

Rack limit

*

Timer adjustment

Pump speed

r/min

750--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

700

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

900

Advance angle

deg.

1.4

0.9

1.9

Timer adjustment_04

Pump speed

r/min

1150

Advance angle

deg.

4

3.5

4.5

Remarks

Finish

Finish

Test data Ex:

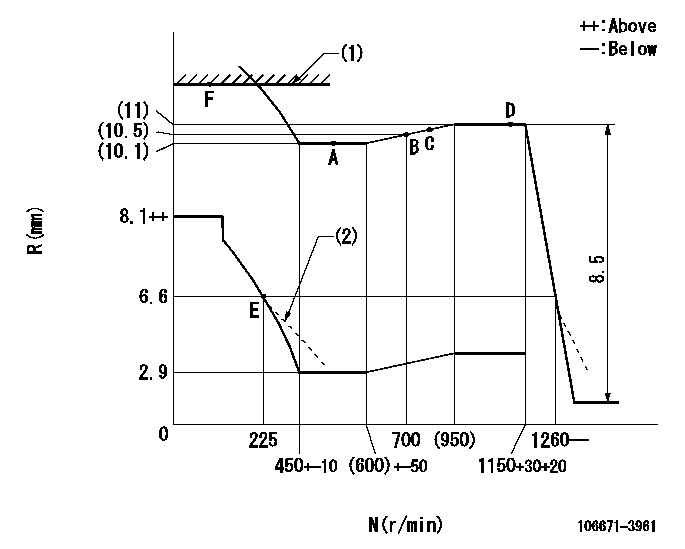

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)RACK LIMIT

(2)Damper spring setting: DL

----------

DL=5.8-0.2mm

----------

----------

DL=5.8-0.2mm

----------

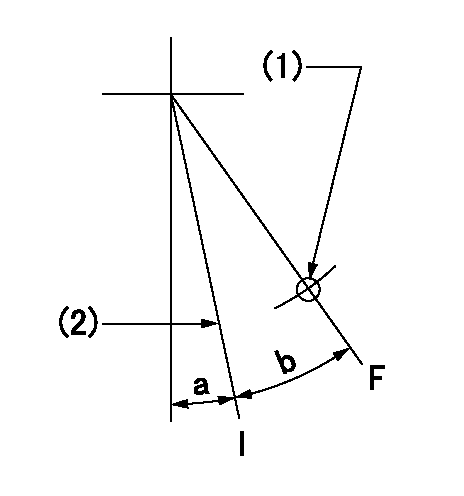

Speed control lever angle

F:Full speed

----------

----------

a=3deg+-5deg

----------

----------

a=3deg+-5deg

0000000901

F:Full load

I:Idle

(1)Use the hole at R = aa

(2)Stopper bolt setting

----------

aa=75mm

----------

a=1deg+-5deg b=(28deg)+-3deg

----------

aa=75mm

----------

a=1deg+-5deg b=(28deg)+-3deg

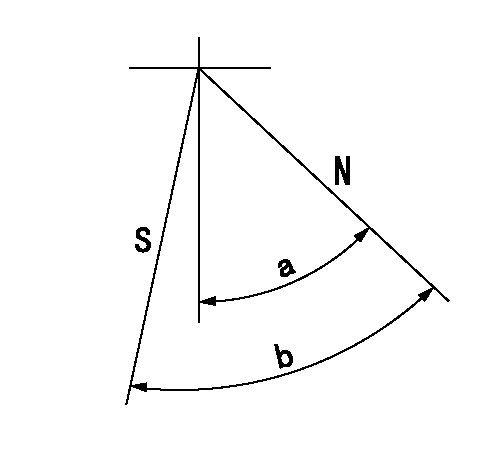

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=40deg+-5deg b=64deg+-5deg

----------

----------

a=40deg+-5deg b=64deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(0deg)

----------

----------

a=(0deg)

Information:

Your truck/engine may not have the same or all of the gauges as shown in the illustrations. The illustrations shown are of typical gauges. Gauges provide a "look" inside the engine. Be sure they are in good working order. You can determine what is the "normal" operating range by observing your gauges over a period of time. Noticeable changes in gauge readings are an indication of potential gauge or engine problems. This also applies to gauge readings that have changed significantly but are still within specifications. The cause of any sudden or significant change in the readings should be determined and corrected. Contact your Caterpillar dealer for assistance as needed.

If no oil pressure is indicated, stop the engine. Engine damage can result.

Oil Pressure - Typical oil pressure range is 40 and 88 psi (275 and 606 kPa) (running at rated engine speed, with SAE 10W-30 oil, at operating temperature.) A lower pressure is normal at low idle.The CHECK ENGINE lamp will illuminate (ON) and a diagnostic code will be logged in the Electronic system if oil pressure drops below 5 psi (35 kPa) at low idle rpm. Water Temperature - Typical water temperature range is 175° to 205°F (79° to 98°C). Maximum allowable temperature is 210°F (99°C) with the cooling system pressurized. Somewhat higher temperatures may occur under certain conditions. Ammeter - Indicates the amount of charge or discharge in the battery charging circuit. Typical operation of the indicator should be slightly to the positive (right) side of "0" (zero).

Do not exceed 2300 rpm in any situation or 2100 rpm if equipped with an auxiliary engine brake system.

Tachometer - Indicates engine rpm (speed). The engine can be operated at high idle without damage, but should not be allowed to overspeed. Overspeeding when downshifting, going downhill, etc., can result in serious damage to your engine. Engine Oil Temperature - Indicates engine oil temperature. Maximum oil temperature at rated speed with a full load is 220°F (104°C).The purpose of engine oil is to lubricate bearings and all internal moving parts and to cool the pistons. The oil cooler transfers heat from the oil to the engine jacket water.If the engine cooling system cannot remove the heat from the jacket water, the oil will not be properly cooled. Higher than normal oil temperature indicates a heat problem has occurred in the lubrication and/or cooling system. This can damage the cylinder heads, liners, pistons and crankshaft bearings. Fuel Level - Indicates fuel level in the fuel tank. Electrically operated, it registers only when the key switch is ON. Fuel Pressure - Indicates fuel pressure to the injection pump. The indicator should register in the NORMAL (green) range. Minimum fuel pressure is 23 psi (160 kPa) when equipped with a numerical gauge and the engine is under load. A drop in fuel pressure usually indicates a dirty or plugged fuel filter. Service Hour Meter - Indicates the total number of clock hours the engine has operated.

If no oil pressure is indicated, stop the engine. Engine damage can result.

Oil Pressure - Typical oil pressure range is 40 and 88 psi (275 and 606 kPa) (running at rated engine speed, with SAE 10W-30 oil, at operating temperature.) A lower pressure is normal at low idle.The CHECK ENGINE lamp will illuminate (ON) and a diagnostic code will be logged in the Electronic system if oil pressure drops below 5 psi (35 kPa) at low idle rpm. Water Temperature - Typical water temperature range is 175° to 205°F (79° to 98°C). Maximum allowable temperature is 210°F (99°C) with the cooling system pressurized. Somewhat higher temperatures may occur under certain conditions. Ammeter - Indicates the amount of charge or discharge in the battery charging circuit. Typical operation of the indicator should be slightly to the positive (right) side of "0" (zero).

Do not exceed 2300 rpm in any situation or 2100 rpm if equipped with an auxiliary engine brake system.

Tachometer - Indicates engine rpm (speed). The engine can be operated at high idle without damage, but should not be allowed to overspeed. Overspeeding when downshifting, going downhill, etc., can result in serious damage to your engine. Engine Oil Temperature - Indicates engine oil temperature. Maximum oil temperature at rated speed with a full load is 220°F (104°C).The purpose of engine oil is to lubricate bearings and all internal moving parts and to cool the pistons. The oil cooler transfers heat from the oil to the engine jacket water.If the engine cooling system cannot remove the heat from the jacket water, the oil will not be properly cooled. Higher than normal oil temperature indicates a heat problem has occurred in the lubrication and/or cooling system. This can damage the cylinder heads, liners, pistons and crankshaft bearings. Fuel Level - Indicates fuel level in the fuel tank. Electrically operated, it registers only when the key switch is ON. Fuel Pressure - Indicates fuel pressure to the injection pump. The indicator should register in the NORMAL (green) range. Minimum fuel pressure is 23 psi (160 kPa) when equipped with a numerical gauge and the engine is under load. A drop in fuel pressure usually indicates a dirty or plugged fuel filter. Service Hour Meter - Indicates the total number of clock hours the engine has operated.