Information injection-pump assembly

ZEXEL

106671-3940

1066713940

HINO

220004940A

220004940a

Rating:

Cross reference number

ZEXEL

106671-3940

1066713940

HINO

220004940A

220004940a

Zexel num

Bosch num

Firm num

Name

106671-3940

220004940A HINO

INJECTION-PUMP ASSEMBLY

EK100 *

EK100 *

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

134424-0920

Overflow valve opening pressure

kPa

162

147

177

Overflow valve opening pressure

kgf/cm2

1.65

1.5

1.8

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

4.8

4.74

4.8

Rack position

Point B R=B

Point B R=B

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.75 60.25

Cal 1-4 deg. 60 59.75 60.25

Difference between angles 2

Cyl.1-2 deg. 120 119.75 120.25

Cyl.1-2 deg. 120 119.75 120.25

Difference between angles 3

Cal 1-6 deg. 180 179.75 180.25

Cal 1-6 deg. 180 179.75 180.25

Difference between angles 4

Cal 1-3 deg. 240 239.75 240.25

Cal 1-3 deg. 240 239.75 240.25

Difference between angles 5

Cal 1-5 deg. 300 299.75 300.25

Cal 1-5 deg. 300 299.75 300.25

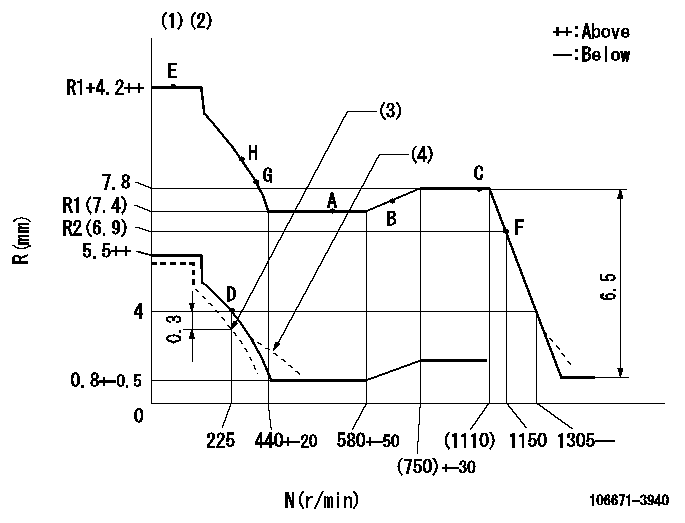

Injection quantity adjustment

Adjusting point

A

Rack position

R1(7.4)

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

142

139

145

Max. variation between cylinders

%

0

-4

4

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

7.7

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

147

145

149

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

7.8

Pump speed

r/min

1075

1075

1075

Average injection quantity

mm3/st.

151

145

157

Max. variation between cylinders

%

0

-4

4

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

D

Rack position

4+-0.5

Pump speed

r/min

225

225

225

Average injection quantity

mm3/st.

10

7

13

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Lever ratio: RT

(2)Target shim dimension: TH

(3)Set to idle at shipping.

(4)Damper spring setting: DL

----------

RT=0.8 TH=2.2mm DL=3.5-0.2mm

----------

----------

RT=0.8 TH=2.2mm DL=3.5-0.2mm

----------

Timer adjustment

(1)Adjusting range

(2)Step response time

(N): Speed of the pump

(L): Load

(theta) Advance angle

(Srd1) Step response time 1

(Srd2) Step response time 2

1. Adjusting conditions for the variable timer

(1)Adjust the clearance between the pickup and the protrusion to L.

----------

L=1-0.2mm N2=800r/min C2=(7deg) t1=2--sec. t2=2--sec.

----------

N1=950+-50r/min P1=0kPa(0kgf/cm2) P2=392kPa(4kgf/cm2) C1=7+-0.3deg R01=0/4 load R02=4/4 load

----------

L=1-0.2mm N2=800r/min C2=(7deg) t1=2--sec. t2=2--sec.

----------

N1=950+-50r/min P1=0kPa(0kgf/cm2) P2=392kPa(4kgf/cm2) C1=7+-0.3deg R01=0/4 load R02=4/4 load

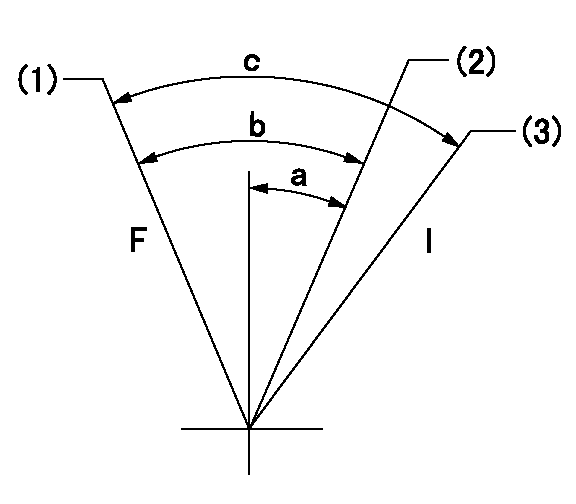

Speed control lever angle

F:Full speed

----------

----------

a=12deg+-5deg

----------

----------

a=12deg+-5deg

0000000901

F:Full load

I:Idle

(1)Use the hole at R = aa

(2)Set point D

(3)At shipping

----------

aa=50mm

----------

a=16deg+-5deg b=35deg+-3deg c=36.5deg+-5deg

----------

aa=50mm

----------

a=16deg+-5deg b=35deg+-3deg c=36.5deg+-5deg

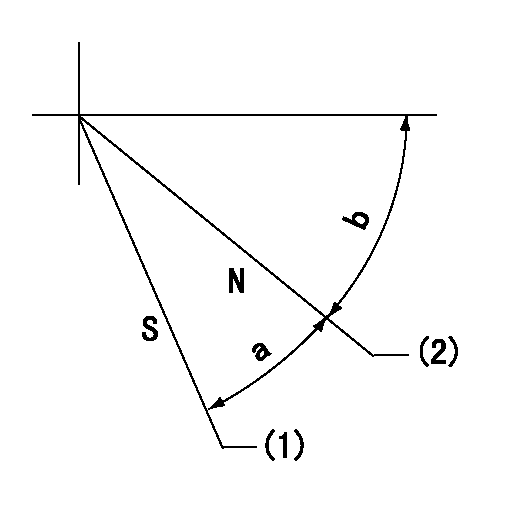

Stop lever angle

N:Engine manufacturer's normal use

S:Stop the pump.

(1)Rack position = aa

(2)Rack position bb

----------

aa=2mm bb=10mm

----------

a=24deg+-5deg b=55deg+-5deg

----------

aa=2mm bb=10mm

----------

a=24deg+-5deg b=55deg+-5deg

0000001501 RACK SENSOR

(VR) measurement voltage

(I) Part number of the control unit

(G) Apply red paint.

(H): End surface of the pump

1. Rack sensor adjustment (-0620)

(1)Fix the speed control lever at the full position

(2)Set the speed to N1 r/min.

(If the boost compensator is provided, apply boost pressure.)

(3)Adjust the bobbin (A) so that the rack sensor's output voltage is VR+-0.01.

(4)At that time, rack position must be Ra.

(5)Apply G at two places.

Connecting part between the joint (B) and the nut (F)

Connecting part between the joint (B) and the end surface of the pump (H)

----------

N1=900r/min Ra=(7.8)mm

----------

----------

N1=900r/min Ra=(7.8)mm

----------

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(0deg)

----------

----------

a=(0deg)

Information:

Coolant Water

The minerals (calcium and magnesium) in hard water can combine with cooling system conditioner additives (silicates and phosphates) to drop out of solution and collect inside the radiator.The minerals (silicates, phosphates, calcium and magnesium) can also accumulate onto hot engine surfaces and reduce the effectiveness of the cooling system, especially after a number of heating and cooling cycles. Distilled water is recommended because of less mineral drop out than hard or tap water. Tap water, artificially softened with salt, is not recommended for use in your engine's cooling system. Use water that meets the minimum acceptable water requirement to prevent drop-out of these chemical compounds.To determine your water characteristics, contact the local water department, agricultural agent or an independent laboratory to perform the testing service.Antifreeze

Caterpillar recommends that the coolant mix contain a minimum of 30% Caterpillar Antifreeze, or equivalent and acceptable water to maintain an adequate water pump cavitation temperature for efficient water pump performance.Premix coolant solution to provide protection to the lowest expected outside (ambient) temperature. Pure undiluted antifreeze will freeze at -10°F (-23°C).Only use a greater concentration (above 30%) of Caterpillar Antifreeze as needed for anticipated outside (ambient) temperatures. Do not exceed a coolant mixture of 60% antifreeze to water since a concentration above 60% antifreeze will reduce the engine's freeze protection and increase the possibility of deposit formation in the cooling system.

Use Caterpillar Antifreeze or ASTM D4985-89 (GM Specification 6038-M) Antifreeze. Caterpillar Antifreeze is available through your Caterpillar dealer in quantities that follow. Most commercial antifreezes are formulated for gasoline engine applications and will, therefore, have high silicate content. Caterpillar Antifreeze is formulated with a low silicate content and the proper coolant additives for heavy duty diesel engines.ASTM D4985-89 (GM Specification 6038-M) is a low silicate antifreeze, but supplemental coolant additive must be added. Make proper antifreeze additions.Adding pure antifreeze as a makeup solution for cooling system top-off is an unacceptable practice. It increases the concentration of antifreeze in the cooling system which increases the concentration of dissolved solids and undissolved chemical inhibitors in the cooling system. Add antifreeze mixed with acceptable water to the same freeze protection as your cooling system. Use the chart below to assist in determining the concentration of antifreeze to use. Check the coolant solution frequently in cold weather for glycol concentration with the 5P0957 or 5P3514 Coolant Tester to ensure adequate protection. Both testers are identical except temperature scale. They give immediate, accurate readings and can be used for antifreeze/coolants that contain ethylene or propylene glycol. Both are available at your Caterpillar dealer.If propylene glycol based antifreeze is used, DO NOT allow concentration greater than a 50/50 antifreeze to water mixture. The measurement of freeze protection must be made with a refractive-type tester (5P0957 or 5P3514) rather than a hydrometer-type, which can be used to test ethylene glycol based antifreeze.Supplemental Coolant Additive

Supplemental coolant additive is necessary to prevent rust, scale, pitting and/or corrosion of engine parts that coolant comes in contact with. Most antifreeze solutions DO NOT contain

The minerals (calcium and magnesium) in hard water can combine with cooling system conditioner additives (silicates and phosphates) to drop out of solution and collect inside the radiator.The minerals (silicates, phosphates, calcium and magnesium) can also accumulate onto hot engine surfaces and reduce the effectiveness of the cooling system, especially after a number of heating and cooling cycles. Distilled water is recommended because of less mineral drop out than hard or tap water. Tap water, artificially softened with salt, is not recommended for use in your engine's cooling system. Use water that meets the minimum acceptable water requirement to prevent drop-out of these chemical compounds.To determine your water characteristics, contact the local water department, agricultural agent or an independent laboratory to perform the testing service.Antifreeze

Caterpillar recommends that the coolant mix contain a minimum of 30% Caterpillar Antifreeze, or equivalent and acceptable water to maintain an adequate water pump cavitation temperature for efficient water pump performance.Premix coolant solution to provide protection to the lowest expected outside (ambient) temperature. Pure undiluted antifreeze will freeze at -10°F (-23°C).Only use a greater concentration (above 30%) of Caterpillar Antifreeze as needed for anticipated outside (ambient) temperatures. Do not exceed a coolant mixture of 60% antifreeze to water since a concentration above 60% antifreeze will reduce the engine's freeze protection and increase the possibility of deposit formation in the cooling system.

Use Caterpillar Antifreeze or ASTM D4985-89 (GM Specification 6038-M) Antifreeze. Caterpillar Antifreeze is available through your Caterpillar dealer in quantities that follow. Most commercial antifreezes are formulated for gasoline engine applications and will, therefore, have high silicate content. Caterpillar Antifreeze is formulated with a low silicate content and the proper coolant additives for heavy duty diesel engines.ASTM D4985-89 (GM Specification 6038-M) is a low silicate antifreeze, but supplemental coolant additive must be added. Make proper antifreeze additions.Adding pure antifreeze as a makeup solution for cooling system top-off is an unacceptable practice. It increases the concentration of antifreeze in the cooling system which increases the concentration of dissolved solids and undissolved chemical inhibitors in the cooling system. Add antifreeze mixed with acceptable water to the same freeze protection as your cooling system. Use the chart below to assist in determining the concentration of antifreeze to use. Check the coolant solution frequently in cold weather for glycol concentration with the 5P0957 or 5P3514 Coolant Tester to ensure adequate protection. Both testers are identical except temperature scale. They give immediate, accurate readings and can be used for antifreeze/coolants that contain ethylene or propylene glycol. Both are available at your Caterpillar dealer.If propylene glycol based antifreeze is used, DO NOT allow concentration greater than a 50/50 antifreeze to water mixture. The measurement of freeze protection must be made with a refractive-type tester (5P0957 or 5P3514) rather than a hydrometer-type, which can be used to test ethylene glycol based antifreeze.Supplemental Coolant Additive

Supplemental coolant additive is necessary to prevent rust, scale, pitting and/or corrosion of engine parts that coolant comes in contact with. Most antifreeze solutions DO NOT contain

Have questions with 106671-3940?

Group cross 106671-3940 ZEXEL

Hino

106671-3940

220004940A

INJECTION-PUMP ASSEMBLY

EK100

EK100