Information injection-pump assembly

ZEXEL

106671-3841

1066713841

HINO

220004591A

220004591a

Rating:

Service parts 106671-3841 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

23600-1621

12.

Open Pre:MPa(Kqf/cm2)

14.7{150}/21.6{220}

15.

NOZZLE SET

Include in #1:

106671-3841

as INJECTION-PUMP ASSEMBLY

Cross reference number

ZEXEL

106671-3841

1066713841

HINO

220004591A

220004591a

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

134424-0920

Overflow valve opening pressure

kPa

162

147

177

Overflow valve opening pressure

kgf/cm2

1.65

1.5

1.8

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

4.8

4.74

4.8

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.75 60.25

Cal 1-4 deg. 60 59.75 60.25

Difference between angles 2

Cyl.1-2 deg. 120 119.75 120.25

Cyl.1-2 deg. 120 119.75 120.25

Difference between angles 3

Cal 1-6 deg. 180 179.75 180.25

Cal 1-6 deg. 180 179.75 180.25

Difference between angles 4

Cal 1-3 deg. 240 239.75 240.25

Cal 1-3 deg. 240 239.75 240.25

Difference between angles 5

Cal 1-5 deg. 300 299.75 300.25

Cal 1-5 deg. 300 299.75 300.25

Injection quantity adjustment

Adjusting point

A

Rack position

7.9

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

153

150

156

Max. variation between cylinders

%

0

-4

4

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

7.9

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

151

149

153

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

8.3

Pump speed

r/min

1075

1075

1075

Average injection quantity

mm3/st.

159

156

162

Max. variation between cylinders

%

0

-4

4

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

D

Rack position

4+-0.5

Pump speed

r/min

225

225

225

Average injection quantity

mm3/st.

13

10

16

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Injection quantity adjustment_05

Adjusting point

E

Rack position

8.6+-0.5

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

140

140

150

Fixing the lever

*

Rack limit

*

Injection quantity adjustment_06

Adjusting point

F

Rack position

7.2

Pump speed

r/min

1150

1150

1150

Average injection quantity

mm3/st.

134.7

129.7

139.7

Fixing the lever

*

Timer adjustment

Pump speed

r/min

865+50

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

1075

Advance angle

deg.

4.5

4.2

4.8

Remarks

Finish

Finish

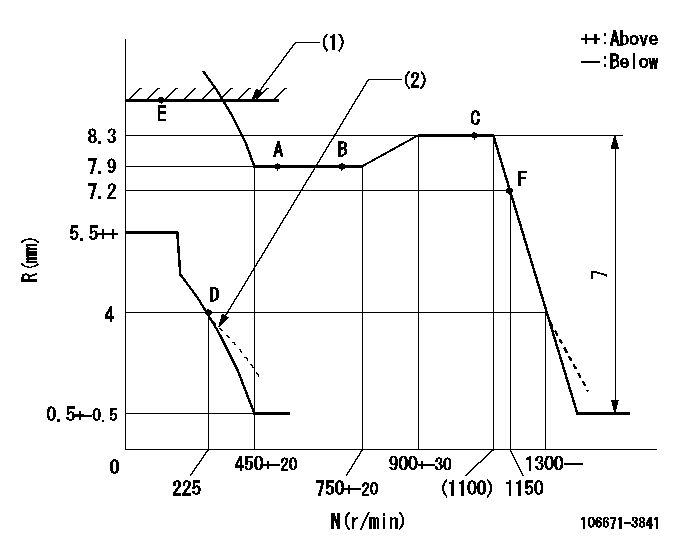

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)RACK LIMIT: R1

(2)Damper spring setting: DL

----------

R1=(8.6)mm DL=3.3-0.2mm

----------

----------

R1=(8.6)mm DL=3.3-0.2mm

----------

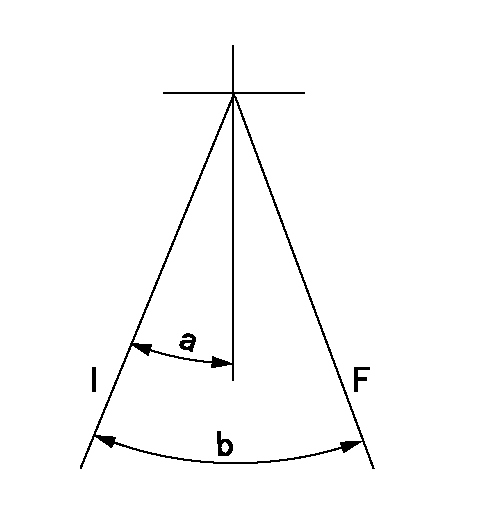

Speed control lever angle

F:Full speed

----------

----------

a=17deg+-5deg

----------

----------

a=17deg+-5deg

0000000901

F:Full load

I:Idle

----------

----------

a=17deg+-5deg b=39deg+-3deg

----------

----------

a=17deg+-5deg b=39deg+-3deg

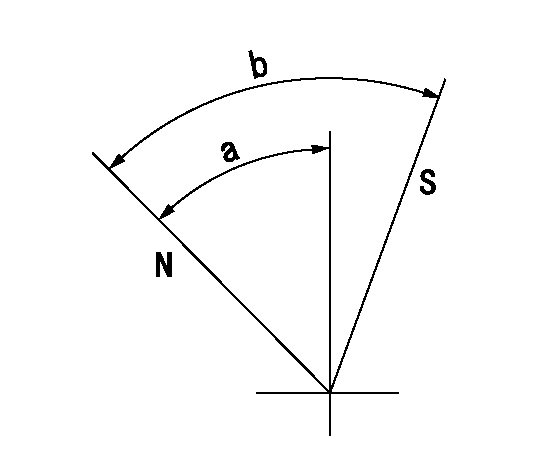

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=40deg+-5deg b=64deg+-5deg

----------

----------

a=40deg+-5deg b=64deg+-5deg

0000001501 MICRO SWITCH

Switch adjustment

Adjust the bolt so that the lower lever position is obtained when the switch is turned ON.

(1)Speed N1

(2)Rack position Ra

----------

N1=300+25r/min Ra=4mm

----------

----------

N1=300+25r/min Ra=4mm

----------

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(0deg)

----------

----------

a=(0deg)

Information:

You must read and understand the warnings and instructions contained in the Safety section of this manual before performing any operation or maintenance procedures.Before proceeding with Every 50 Hour maintenance, perform all Daily maintenance requirements.Dust Collector

Never run the engine without an air cleaner installed. Never run the engine with a damaged air cleaner. Do not use filter elements with damaged pleats, gaskets or seals. Dirt entering the engine causes premature wear and damage to engine components. Air cleaners prevent airborne debris from entering the engine through the air inlet.

Clean

Typical two stage air cleaner. Individual applications may be different.1. Remove the air cleaner cap (1). Remove the dust collector cup (2).2. Wipe dust collector cup with a clean, dry cloth.3. Install the cup. Install and secure the cap. If equipped with a heavy duty air cleaner: refer to the Heavy Duty Air Cleaner topic in the Daily section of this manual for information about cleaning the dust collector cup.Light Duty Air Cleaner (If Equipped)

Light duty air cleaners are not serviceable (washable). Light duty air cleaners are intended for a 50 service hours of maximum use, or one year, whichever occurs first. However, engines operating in a severe environment may require more frequent air cleaner replacement.Dust conditions vary for different operating environments. Service the air cleaner at regular intervals as determined by the operating environment. Check the air cleaner service indicator (if equipped) daily.Check the air cleaner for cleanliness and damage such as rips and tears. Replace the air cleaner element at the required service interval, or more often as determined by the operating environmental dust conditions. To Replace the Light Duty Air Cleaner Element: 1. Loosen the clamp (2) fastening the air cleaner element (1) to the air inlet, and remove the dirty element and clamp.2. Install the clamp on a new element.3. Install the new element to the air inlet and tighten the clamp.

Never run the engine without an air cleaner installed. Never run the engine with a damaged air cleaner. Do not use filter elements with damaged pleats, gaskets or seals. Dirt entering the engine causes premature wear and damage to engine components. Air cleaners prevent airborne debris from entering the engine through the air inlet.

Clean

Typical two stage air cleaner. Individual applications may be different.1. Remove the air cleaner cap (1). Remove the dust collector cup (2).2. Wipe dust collector cup with a clean, dry cloth.3. Install the cup. Install and secure the cap. If equipped with a heavy duty air cleaner: refer to the Heavy Duty Air Cleaner topic in the Daily section of this manual for information about cleaning the dust collector cup.Light Duty Air Cleaner (If Equipped)

Light duty air cleaners are not serviceable (washable). Light duty air cleaners are intended for a 50 service hours of maximum use, or one year, whichever occurs first. However, engines operating in a severe environment may require more frequent air cleaner replacement.Dust conditions vary for different operating environments. Service the air cleaner at regular intervals as determined by the operating environment. Check the air cleaner service indicator (if equipped) daily.Check the air cleaner for cleanliness and damage such as rips and tears. Replace the air cleaner element at the required service interval, or more often as determined by the operating environmental dust conditions. To Replace the Light Duty Air Cleaner Element: 1. Loosen the clamp (2) fastening the air cleaner element (1) to the air inlet, and remove the dirty element and clamp.2. Install the clamp on a new element.3. Install the new element to the air inlet and tighten the clamp.