Information injection-pump assembly

ZEXEL

106671-3820

1066713820

HINO

220004520A

220004520a

Rating:

Cross reference number

ZEXEL

106671-3820

1066713820

HINO

220004520A

220004520a

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

134424-0920

Overflow valve opening pressure

kPa

177

143

211

Overflow valve opening pressure

kgf/cm2

1.8

1.45

2.15

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.3

3.24

3.3

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.75 60.25

Cal 1-4 deg. 60 59.75 60.25

Difference between angles 2

Cyl.1-2 deg. 120 119.75 120.25

Cyl.1-2 deg. 120 119.75 120.25

Difference between angles 3

Cal 1-6 deg. 180 179.75 180.25

Cal 1-6 deg. 180 179.75 180.25

Difference between angles 4

Cal 1-3 deg. 240 239.75 240.25

Cal 1-3 deg. 240 239.75 240.25

Difference between angles 5

Cal 1-5 deg. 300 299.75 300.25

Cal 1-5 deg. 300 299.75 300.25

Injection quantity adjustment

Adjusting point

-

Rack position

11+-0.5

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

144

142

146

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

H

Rack position

7+-0.5

Pump speed

r/min

225

225

225

Average injection quantity

mm3/st.

15

12

18

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(11.1)

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

144

142

146

Basic

*

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1+0.6

Pump speed

r/min

1150

1150

1150

Average injection quantity

mm3/st.

154

148

160

Fixing the lever

*

Injection quantity adjustment_05

Adjusting point

C

Rack position

R1-0.3

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

132

126

138

Fixing the lever

*

Injection quantity adjustment_06

Adjusting point

I

Rack position

R2

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

126.3

119.3

133.3

Fixing the lever

*

Rack limit

*

Timer adjustment

Pump speed

r/min

1000--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

950

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1000

Advance angle

deg.

1.5

Timer adjustment_04

Pump speed

r/min

1050

Advance angle

deg.

1.9

1.4

2.4

Timer adjustment_05

Pump speed

r/min

1150

Advance angle

deg.

4.5

4.2

4.8

Remarks

Finish

Finish

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Torque cam stamping: T1

(2)RACK LIMIT

----------

T1=B06

----------

----------

T1=B06

----------

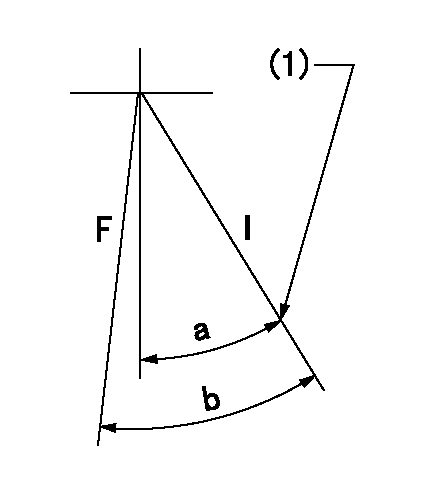

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt set position 'H'

----------

----------

a=40deg+-5deg b=(48deg)+-3deg

----------

----------

a=40deg+-5deg b=(48deg)+-3deg

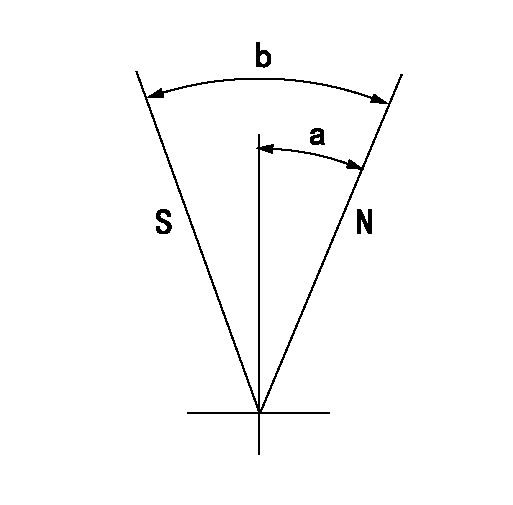

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=15deg+-5deg b=38.5deg+-5deg

----------

----------

a=15deg+-5deg b=38.5deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(0deg)

----------

----------

a=(0deg)

Information:

Lubricant Viscosity Recommendations

See chart for recommended viscosity and temperature range. The required performance criteria for the oil is defined in the previous Lubricant Specification section.The minimum temperature for the viscosity grade provides guidelines for the lowest starting temperature with a "cold soaked" engine. Base stocks for blending the oil formulations do differ, and variations can exist within a viscosity grade on low temperature characteristics. Therefore, a particular oil may allow lower starting temperatures than given in the chart. Your oil supplier can provide additional information on oil properties.The recommendation is to use the highest viscosity oil possible. Even though the ambient temperature may be low, operating engines can still be subjected to normal oil temperatures because of regulated temperature components. Higher viscosity fluids provide better protection to all components contacted during the full day work cycle.Multi-viscosity oils are preferred because of full protection through a wider temperature range. See chart for recommended viscosity and temperature range.To determine if the oil in the crankcase will flow in cold weather, remove the oil dipstick before starting the engine. If the oil flows off, the oil is fluid enough to circulate properly.Lubricant Viscosity Chart

Refill Capacities

These refill capacities reflect the crankcase capacity plus filter. Auxiliary oil filter systems will require additional oil. For all auxiliary oil filter system information consult the OEM or auxiliary oil filter system manufacturer.In order to properly maintain the cooling system, Total Cooling System capacity must be known. This capacity information will be needed to determine the amount of antifreeze and coolant additive (conditioner) required for the cooling system.

See chart for recommended viscosity and temperature range. The required performance criteria for the oil is defined in the previous Lubricant Specification section.The minimum temperature for the viscosity grade provides guidelines for the lowest starting temperature with a "cold soaked" engine. Base stocks for blending the oil formulations do differ, and variations can exist within a viscosity grade on low temperature characteristics. Therefore, a particular oil may allow lower starting temperatures than given in the chart. Your oil supplier can provide additional information on oil properties.The recommendation is to use the highest viscosity oil possible. Even though the ambient temperature may be low, operating engines can still be subjected to normal oil temperatures because of regulated temperature components. Higher viscosity fluids provide better protection to all components contacted during the full day work cycle.Multi-viscosity oils are preferred because of full protection through a wider temperature range. See chart for recommended viscosity and temperature range.To determine if the oil in the crankcase will flow in cold weather, remove the oil dipstick before starting the engine. If the oil flows off, the oil is fluid enough to circulate properly.Lubricant Viscosity Chart

Refill Capacities

These refill capacities reflect the crankcase capacity plus filter. Auxiliary oil filter systems will require additional oil. For all auxiliary oil filter system information consult the OEM or auxiliary oil filter system manufacturer.In order to properly maintain the cooling system, Total Cooling System capacity must be known. This capacity information will be needed to determine the amount of antifreeze and coolant additive (conditioner) required for the cooling system.