Information injection-pump assembly

ZEXEL

106671-3800

1066713800

HINO

220004510A

220004510a

Rating:

Cross reference number

ZEXEL

106671-3800

1066713800

HINO

220004510A

220004510a

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve (drive side)

134424-1420

Overflow valve opening pressure (drive side)

kPa

162

147

177

Overflow valve opening pressure (drive side)

kgf/cm2

1.65

1.5

1.8

Overflow valve (governor side)

134424-1520

Overflow valve opening pressure (governor side)

kPa

162

147

177

Overflow valve opening pressure (governor side)

kgf/cm2

1.65

1.5

1.8

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

4.5

4.44

4.5

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.75 60.25

Cal 1-4 deg. 60 59.75 60.25

Difference between angles 2

Cyl.1-2 deg. 120 119.75 120.25

Cyl.1-2 deg. 120 119.75 120.25

Difference between angles 3

Cal 1-6 deg. 180 179.75 180.25

Cal 1-6 deg. 180 179.75 180.25

Difference between angles 4

Cal 1-3 deg. 240 239.75 240.25

Cal 1-3 deg. 240 239.75 240.25

Difference between angles 5

Cal 1-5 deg. 300 299.75 300.25

Cal 1-5 deg. 300 299.75 300.25

Injection quantity adjustment

Adjusting point

A

Rack position

7.9

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

132.7

130.7

134.7

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Boost pressure

kPa

33.3

33.3

Boost pressure

mmHg

250

250

Injection quantity adjustment_02

Adjusting point

B

Rack position

7.1+-0.5

Pump speed

r/min

1250

1250

1250

Average injection quantity

mm3/st.

111.4

107.4

115.4

Max. variation between cylinders

%

0

-5

5

Fixing the lever

*

Boost pressure

kPa

33.3

33.3

Boost pressure

mmHg

250

250

Injection quantity adjustment_03

Adjusting point

C

Rack position

7.9

Pump speed

r/min

1150

1150

1150

Average injection quantity

mm3/st.

133.7

130.7

136.7

Max. variation between cylinders

%

0

-5

5

Fixing the lever

*

Boost pressure

kPa

33.3

33.3

Boost pressure

mmHg

250

250

Injection quantity adjustment_04

Adjusting point

D

Rack position

8

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

135.8

132.8

138.8

Max. variation between cylinders

%

0

-5

5

Fixing the lever

*

Boost pressure

kPa

33.3

33.3

Boost pressure

mmHg

250

250

Injection quantity adjustment_05

Adjusting point

E

Rack position

4.7+-0.5

Pump speed

r/min

225

225

225

Average injection quantity

mm3/st.

12.3

9.3

15.3

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_06

Adjusting point

F

Rack position

7.7+-0.5

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

89

89

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_07

Adjusting point

G

Rack position

-

Pump speed

r/min

200

200

200

Average injection quantity

mm3/st.

156.3

156.3

166.3

Fixing the lever

*

Boost pressure

kPa

33.3

33.3

Boost pressure

mmHg

250

250

Injection quantity adjustment_08

Adjusting point

H

Rack position

6.1+-0.5

Pump speed

r/min

400

400

400

Average injection quantity

mm3/st.

67.3

65.3

69.3

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Boost compensator adjustment

Pump speed

r/min

700

700

700

Rack position

(6.1)

Boost pressure

kPa

3.3

3.3

5.3

Boost pressure

mmHg

25

25

40

Boost compensator adjustment_02

Pump speed

r/min

700

700

700

Rack position

7.9

Boost pressure

kPa

16

16

16

Boost pressure

mmHg

120

120

120

Timer adjustment

Pump speed

r/min

975--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

925

Advance angle

deg.

0.3

Timer adjustment_03

Pump speed

r/min

1050

Advance angle

deg.

1.3

0.8

1.8

Timer adjustment_04

Pump speed

r/min

1150

Advance angle

deg.

2.5

2.2

2.8

Remarks

Finish

Finish

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Damper spring setting: DL

(2)RACK LIMIT

----------

DL=4.2-0.2mm

----------

----------

DL=4.2-0.2mm

----------

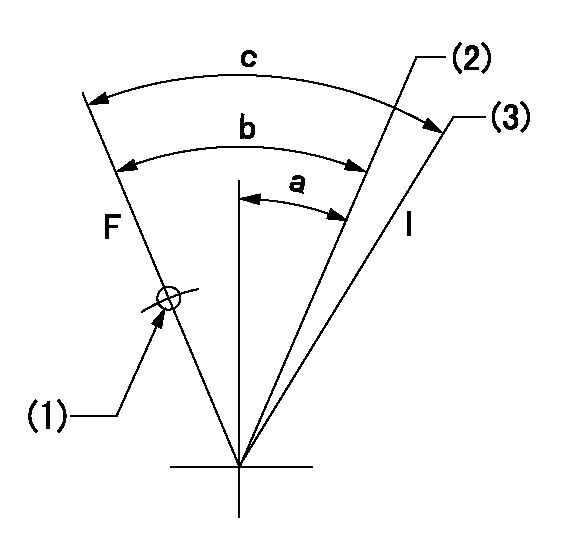

Speed control lever angle

F:Full speed

----------

----------

a=7deg+-5deg

----------

----------

a=7deg+-5deg

0000000901

F:Full load

I:Idle

(1)Use the hole at R = aa

(2)Point E setting

(3)At delivery

----------

aa=54mm

----------

a=14deg+-5deg b=39deg+-3deg c=39deg+-5deg

----------

aa=54mm

----------

a=14deg+-5deg b=39deg+-3deg c=39deg+-5deg

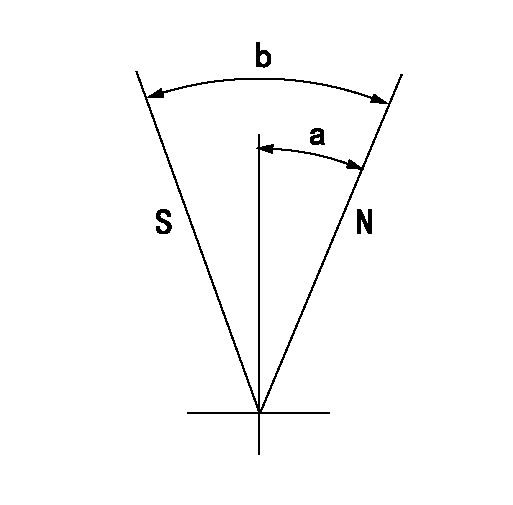

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=39deg+-5deg b=48.5deg+-5deg

----------

----------

a=39deg+-5deg b=48.5deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(50deg)

----------

----------

a=(50deg)

Information:

Air-to-air aftercooling (ATAAC) systems are simple, reliable, and easy to maintain. Generally, ATAAC benefits one or two of the following areas: * Improved fuel consumption* Lower emissions* Increased power In some cases all three may be improved.Operation of ATAAC

Inlet air is pulled through the air cleaner, compressed and heated by the compressor wheel in the compressor side of the turbocharger to about 150°C (300°F). The heated air is then pushed through the air to air aftercooler core and moved to the air inlet manifold in the cylinder head at about 43°C (110°F).

Radiator Core (1) and Aftercooler Core (2).Cooling the inlet air increases combustion efficiency, which helps to lower fuel consumption and increase horsepower output. The aftercooler core (2) is a separate cooler core installed behind the standard radiator core (1). Ambient temperature is moved across both cores by the engine fan- this cools the turbocharged inlet air and the engine coolant.Lower inlet air temperature allows more air to enter the cylinder. More complete fuel combustion and reduced exhaust emissions are the results. Air-to-air aftercoolers can achieve charge air temperatures lower than water-to-air systems. The lower air temperatures provide improved efficiency.

To maintain an adequate water pump cavitation temperature for efficient water pump performance in an Air-to-Air Aftercooled engine: Caterpillar recommends that the coolant mix contain a minimum of 30 percent Caterpillar Antifreeze, or equivalent.

Air Inlet System

An air hose failure or a significant air inlet system leak will cause a large drop in boost pressure and power. The engine can be operated at this power level for a short period of time, however, sustained operation under this condition should be avoided.A slight reduction in power or response, or a small increase in exhaust temperature may indicate a small air leak in the charge air cooler core or piping.If air leaking is suspected, inspect the air inlet hoses, elbows and gaskets for cracks or damage. Replace the parts as needed. Check for loose clamps and tighten the clamps as needed.Radiator Restrictions

Caterpillar discourages the use of air flow restriction devices mounted in front of radiators with air-to-air aftercooled engines. Air flow restriction can cause higher exhaust temperatures, power loss, excessive fan usage, and a reduction in fuel economy.If an air flow restriction device must be used, the device should have a permanent opening directly in line with the fan hub. The device must have a minimum opening dimension of at least 770 cm2 (120 in2).A centered opening, directly in line with the fan hub, is specified to provide sensing when viscous fan drives are used and/or to prevent an interrupted air flow on the fan blades. Interrupted air flow on the fan blades could cause a fan failure.Caterpillar recommends that a package include an inlet manifold temperature device, such as a light indicator, buzzer, etc., set at 65°C (150°F) and/or installation of an inlet air temperature gauge. For the ATAAC (Air-To-Air Aftercooled) engines, air temperature in the inlet manifold should not exceed 65°C (150°F). Temperatures exceeding this limit can cause power loss

Inlet air is pulled through the air cleaner, compressed and heated by the compressor wheel in the compressor side of the turbocharger to about 150°C (300°F). The heated air is then pushed through the air to air aftercooler core and moved to the air inlet manifold in the cylinder head at about 43°C (110°F).

Radiator Core (1) and Aftercooler Core (2).Cooling the inlet air increases combustion efficiency, which helps to lower fuel consumption and increase horsepower output. The aftercooler core (2) is a separate cooler core installed behind the standard radiator core (1). Ambient temperature is moved across both cores by the engine fan- this cools the turbocharged inlet air and the engine coolant.Lower inlet air temperature allows more air to enter the cylinder. More complete fuel combustion and reduced exhaust emissions are the results. Air-to-air aftercoolers can achieve charge air temperatures lower than water-to-air systems. The lower air temperatures provide improved efficiency.

To maintain an adequate water pump cavitation temperature for efficient water pump performance in an Air-to-Air Aftercooled engine: Caterpillar recommends that the coolant mix contain a minimum of 30 percent Caterpillar Antifreeze, or equivalent.

Air Inlet System

An air hose failure or a significant air inlet system leak will cause a large drop in boost pressure and power. The engine can be operated at this power level for a short period of time, however, sustained operation under this condition should be avoided.A slight reduction in power or response, or a small increase in exhaust temperature may indicate a small air leak in the charge air cooler core or piping.If air leaking is suspected, inspect the air inlet hoses, elbows and gaskets for cracks or damage. Replace the parts as needed. Check for loose clamps and tighten the clamps as needed.Radiator Restrictions

Caterpillar discourages the use of air flow restriction devices mounted in front of radiators with air-to-air aftercooled engines. Air flow restriction can cause higher exhaust temperatures, power loss, excessive fan usage, and a reduction in fuel economy.If an air flow restriction device must be used, the device should have a permanent opening directly in line with the fan hub. The device must have a minimum opening dimension of at least 770 cm2 (120 in2).A centered opening, directly in line with the fan hub, is specified to provide sensing when viscous fan drives are used and/or to prevent an interrupted air flow on the fan blades. Interrupted air flow on the fan blades could cause a fan failure.Caterpillar recommends that a package include an inlet manifold temperature device, such as a light indicator, buzzer, etc., set at 65°C (150°F) and/or installation of an inlet air temperature gauge. For the ATAAC (Air-To-Air Aftercooled) engines, air temperature in the inlet manifold should not exceed 65°C (150°F). Temperatures exceeding this limit can cause power loss