Information injection-pump assembly

BOSCH

9 400 610 838

9400610838

ZEXEL

106671-3387

1066713387

HINO

220004081A

220004081a

Rating:

Service parts 106671-3387 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

23600-1221A

12.

Open Pre:MPa(Kqf/cm2)

21.6{220}

15.

NOZZLE SET

Include in #1:

106671-3387

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 400 610 838

9400610838

ZEXEL

106671-3387

1066713387

HINO

220004081A

220004081a

Zexel num

Bosch num

Firm num

Name

106671-3387

9 400 610 838

220004081A HINO

INJECTION-PUMP ASSEMBLY

EK100 K 14CA INJECTION PUMP ASSY PE6P,6PD PE

EK100 K 14CA INJECTION PUMP ASSY PE6P,6PD PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d]

1404 Test oil ISO4113 or {SAEJ967d]

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

134424-0920

Overflow valve opening pressure

kPa

162

147

177

Overflow valve opening pressure

kgf/cm2

1.65

1.5

1.8

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.3

3.24

3.3

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.75 60.25

Cal 1-4 deg. 60 59.75 60.25

Difference between angles 2

Cyl.1-2 deg. 120 119.75 120.25

Cyl.1-2 deg. 120 119.75 120.25

Difference between angles 3

Cal 1-6 deg. 180 179.75 180.25

Cal 1-6 deg. 180 179.75 180.25

Difference between angles 4

Cal 1-3 deg. 240 239.75 240.25

Cal 1-3 deg. 240 239.75 240.25

Difference between angles 5

Cal 1-5 deg. 300 299.75 300.25

Cal 1-5 deg. 300 299.75 300.25

Injection quantity adjustment

Adjusting point

A

Rack position

10.6

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

129

126

132

Max. variation between cylinders

%

0

-4

4

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

10.9

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

139.5

137.5

141.5

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

11.4

Pump speed

r/min

1150

1150

1150

Average injection quantity

mm3/st.

148

145

151

Max. variation between cylinders

%

0

-4

4

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

D

Rack position

7+-0.5

Pump speed

r/min

225

225

225

Average injection quantity

mm3/st.

15

12

18

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Injection quantity adjustment_05

Adjusting point

E

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

126.3

119.3

133.3

Fixing the lever

*

Rack limit

*

Timer adjustment

Pump speed

r/min

950

Advance angle

deg.

0.5

Timer adjustment_02

Pump speed

r/min

1000

Advance angle

deg.

1.5

Timer adjustment_03

Pump speed

r/min

1050

Advance angle

deg.

1.9

1.4

2.4

Timer adjustment_04

Pump speed

r/min

1150

Advance angle

deg.

4.5

4.2

4.8

Remarks

Finish

Finish

Test data Ex:

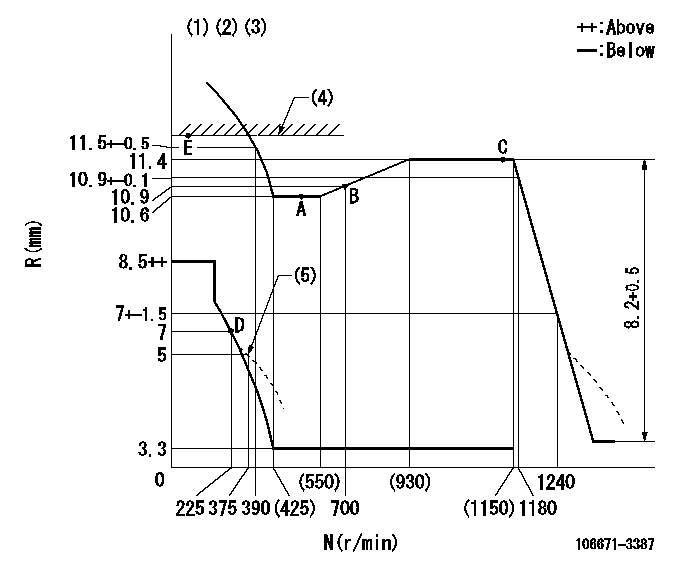

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Lever ratio: RT

(2)Target shim dimension: TH

(3)Tolerance for racks not indicated: +-0.05mm.

(4)RACK LIMIT

(5)Damper spring setting

----------

RT=1 TH=2.2mm

----------

----------

RT=1 TH=2.2mm

----------

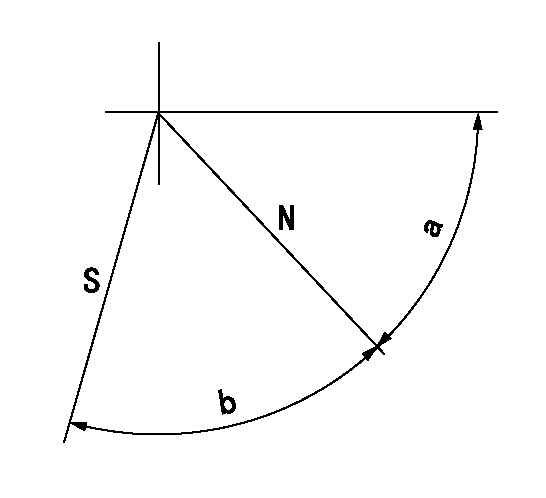

Speed control lever angle

F:Full speed

----------

----------

a=3deg+-5deg

----------

----------

a=3deg+-5deg

0000000901

F:Full load

I:Idle

(1)Stopper bolt setting

----------

----------

a=10deg+-5deg b=27deg+-3deg

----------

----------

a=10deg+-5deg b=27deg+-3deg

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=40deg+-5deg b=64deg+-5deg

----------

----------

a=40deg+-5deg b=64deg+-5deg

0000001501 GOVERNOR TORQUE CONTROL

Dr:Torque control stroke

(A): Without torque control spring capsule

1. Adjustment procedures

(1)Procedure is the same as that for the RFD (former type), except that the positive torque control stroke must be determined at the full lever setting.

2. Procedures for adjustment

(1)Remove the torque control spring capsule.

(2)Operate the pump at approximately N1. (End of idling spring operation < N1.)

(3)Tilt the lever to the full side.

(4)Set so that R = RF.

(5)Increase the speed by pushing in the screw (attached to the bracket on the rear of the tension lever) through the adjusting window.

(6)Adjust so that the torque control stroke Dr1 can be obtained.

(7)Align N2 and N3 with the torque control spring capsule.

3. Final confirmation

(1)After final confirmation, temporarily set the load lever to N = N1, R = idling position.

(2)From this condition, increase speed to N = N4.

(3)Confirm that positive torque control stroke is Dr2.

----------

N1=500r/min N2=(550)r/min N3=(930)r/min N4=1000r/min RF=10.6mm Dr1=0.8mm Dr2=0+0.3mm

----------

----------

N1=500r/min N2=(550)r/min N3=(930)r/min N4=1000r/min RF=10.6mm Dr1=0.8mm Dr2=0+0.3mm

----------

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(0deg)

----------

----------

a=(0deg)

Information:

2. Maintain the oil level to the FULL mark (between the ADD and FULL RANGE zone) on the ENGINE STOPPED WITH OIL COLD side of the dipstick. Do not fill the crankcase above the FULL RANGE zone.3. Remove oil fill cap and add oil if necessary. DO NOT fill the crankcase above the FULL mark on the dipstick.

Do NOT overfill to reach above or to the top of the FULL mark on the dipstick.

Operating your engine when the oil level is above the FULL Range zone could cause your crankshaft to dip into the oil. If this occurs during engine operation, it could result in a loss of power and a possible alarm from high crankcase pressure. Remote mounted or auxiliary filters require additional oil. For all information pertaining to auxiliary filters, refer to the OEM or filter manufacturer's recommendations and instructions for all information regarding auxiliary oil filters.Estimating Oil Consumption

Oil consumption, along with fuel consumption and maintenance information, can be used to estimate total operating cost for your Caterpillar engine. It can also be used to estimate the capacity of a makeup oil system required to accommodate your maintenance intervals.Oil consumption is somewhat proportional to the percent load at which the engine is operating. The higher the percent load, the higher the amount of oil consumed per hour.The oil consumption rate, or BSOC (brake specific oil consumption), measure is grams/brake kW-hour (lb/bhp-hour). The BSOC varies depending on the load on your engine. The established typical mid-life BSOC values for your engine can be determined by contacting your Caterpillar dealer for assistance in determining typical oil consumption for your engine.Oil Consumption as an Overhaul Indicator

When an engine's oil consumption has risen to three times the initial (new) consumption rate due to normal wear, then the engine should be scheduled for overhaul. There may be a corresponding increase in blowby and also a slight increase in fuel consumption. Contact your Caterpillar dealer for assistance in determining typical oil consumption for your engine.Cooling System

Make sure you read and understand the information in the Safety and Cooling System Specifications sections of this manual before you proceed with maintenance of the cooling system.

Check Coolant Level

If Coolant is Low

Refer to the Cooling System Specifications section in this publication for all information pertaining to water, antifreeze and supplemental coolant additive requirements before performing this maintenance procedure.1. Stop the engine and allow the engine to cool before performing this maintenance procedure.2. Release vent valve (if equipped) slowly to relieve pressure. Remove filler cap and inspect condition of cap gasket. Replace cap if gaskets are damaged.3. Maintain the coolant level within 13 mm (1/2 inch) below the bottom of the fill pipe or to the proper level (upper half) on the sight glass (if equipped) by adding make-up coolant (antifreeze and water). Install the filler cap.4. Inspect for leaks or damaged piping. Make repairs if necessary.Air Cleaner Indicator

Typical air cleaner indicator shown.Check the service indicator (if equipped) mounted on the air cleaner. A colored piston showing

Do NOT overfill to reach above or to the top of the FULL mark on the dipstick.

Operating your engine when the oil level is above the FULL Range zone could cause your crankshaft to dip into the oil. If this occurs during engine operation, it could result in a loss of power and a possible alarm from high crankcase pressure. Remote mounted or auxiliary filters require additional oil. For all information pertaining to auxiliary filters, refer to the OEM or filter manufacturer's recommendations and instructions for all information regarding auxiliary oil filters.Estimating Oil Consumption

Oil consumption, along with fuel consumption and maintenance information, can be used to estimate total operating cost for your Caterpillar engine. It can also be used to estimate the capacity of a makeup oil system required to accommodate your maintenance intervals.Oil consumption is somewhat proportional to the percent load at which the engine is operating. The higher the percent load, the higher the amount of oil consumed per hour.The oil consumption rate, or BSOC (brake specific oil consumption), measure is grams/brake kW-hour (lb/bhp-hour). The BSOC varies depending on the load on your engine. The established typical mid-life BSOC values for your engine can be determined by contacting your Caterpillar dealer for assistance in determining typical oil consumption for your engine.Oil Consumption as an Overhaul Indicator

When an engine's oil consumption has risen to three times the initial (new) consumption rate due to normal wear, then the engine should be scheduled for overhaul. There may be a corresponding increase in blowby and also a slight increase in fuel consumption. Contact your Caterpillar dealer for assistance in determining typical oil consumption for your engine.Cooling System

Make sure you read and understand the information in the Safety and Cooling System Specifications sections of this manual before you proceed with maintenance of the cooling system.

Check Coolant Level

If Coolant is Low

Refer to the Cooling System Specifications section in this publication for all information pertaining to water, antifreeze and supplemental coolant additive requirements before performing this maintenance procedure.1. Stop the engine and allow the engine to cool before performing this maintenance procedure.2. Release vent valve (if equipped) slowly to relieve pressure. Remove filler cap and inspect condition of cap gasket. Replace cap if gaskets are damaged.3. Maintain the coolant level within 13 mm (1/2 inch) below the bottom of the fill pipe or to the proper level (upper half) on the sight glass (if equipped) by adding make-up coolant (antifreeze and water). Install the filler cap.4. Inspect for leaks or damaged piping. Make repairs if necessary.Air Cleaner Indicator

Typical air cleaner indicator shown.Check the service indicator (if equipped) mounted on the air cleaner. A colored piston showing

Have questions with 106671-3387?

Group cross 106671-3387 ZEXEL

Hino

106671-3387

9 400 610 838

220004081A

INJECTION-PUMP ASSEMBLY

EK100

EK100