Information injection-pump assembly

ZEXEL

106671-3386

1066713386

HINO

220004080A

220004080a

Rating:

Service parts 106671-3386 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

23600-1221

12.

Open Pre:MPa(Kqf/cm2)

21.6{220}

15.

NOZZLE SET

Include in #1:

106671-3386

as INJECTION-PUMP ASSEMBLY

Cross reference number

ZEXEL

106671-3386

1066713386

HINO

220004080A

220004080a

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

134424-0920

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.3

3.24

3.3

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.75 60.25

Cal 1-4 deg. 60 59.75 60.25

Difference between angles 2

Cyl.1-2 deg. 120 119.75 120.25

Cyl.1-2 deg. 120 119.75 120.25

Difference between angles 3

Cal 1-6 deg. 180 179.75 180.25

Cal 1-6 deg. 180 179.75 180.25

Difference between angles 4

Cal 1-3 deg. 240 239.75 240.25

Cal 1-3 deg. 240 239.75 240.25

Difference between angles 5

Cal 1-5 deg. 300 299.75 300.25

Cal 1-5 deg. 300 299.75 300.25

Injection quantity adjustment

Adjusting point

A

Rack position

10.6

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

129

126

132

Max. variation between cylinders

%

0

-4

4

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

10.9

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

139.5

137.5

141.5

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

11.4

Pump speed

r/min

1150

1150

1150

Average injection quantity

mm3/st.

148

145

151

Max. variation between cylinders

%

0

-4

4

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

D

Rack position

7+-0.5

Pump speed

r/min

225

225

225

Average injection quantity

mm3/st.

15

12

18

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Injection quantity adjustment_05

Adjusting point

E

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

126.3

119.3

133.3

Fixing the lever

*

Timer adjustment

Pump speed

r/min

1000--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

950

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1000

Advance angle

deg.

1.5

Timer adjustment_04

Pump speed

r/min

1050

Advance angle

deg.

1.9

1.4

2.4

Timer adjustment_05

Pump speed

r/min

1150

Advance angle

deg.

4.5

4

5

Remarks

Finish

Finish

Test data Ex:

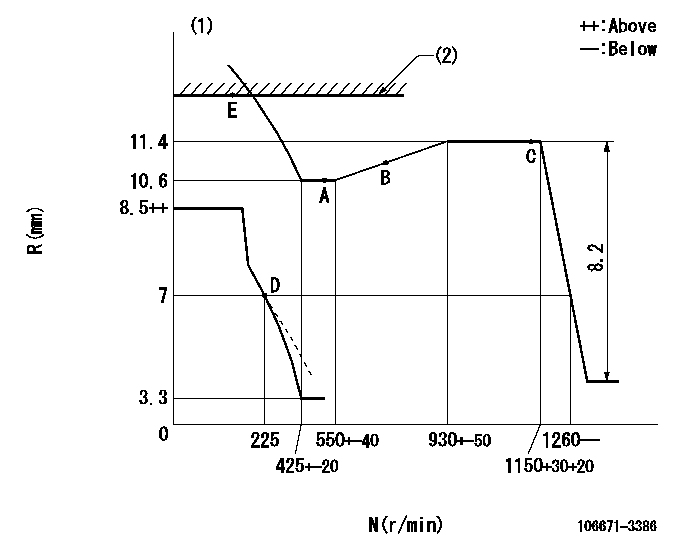

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Beginning of damper spring operation: DL

(2)RACK LIMIT

----------

DL=6.2-0.2mm

----------

----------

DL=6.2-0.2mm

----------

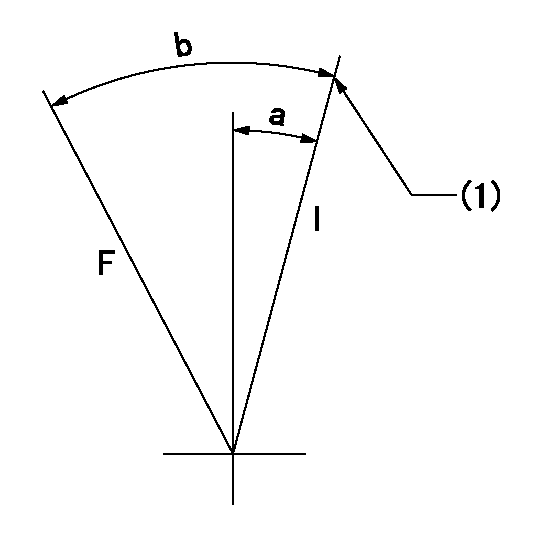

Speed control lever angle

F:Full speed

----------

----------

a=3deg+-5deg

----------

----------

a=3deg+-5deg

0000000901

F:Full load

I:Idle

(1)Stopper bolt setting

----------

----------

a=10deg+-5deg b=27.5deg+-3deg

----------

----------

a=10deg+-5deg b=27.5deg+-3deg

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=15deg+-5deg b=64deg+-5deg

----------

----------

a=15deg+-5deg b=64deg+-5deg

0000001501 GOVERNOR TORQUE CONTROL

Dr:Torque control stroke

(A): Without torque control spring capsule

1. Adjustment procedures

(1)Procedure is the same as that for the RFD (former type), except that the positive torque control stroke must be determined at the full lever setting.

2. Procedures for adjustment

(1)Remove the torque control spring capsule.

(2)Operate the pump at approximately N1. (End of idling spring operation < N1.)

(3)Tilt the lever to the full side.

(4)Set so that R = RF.

(5)Increase the speed by pushing in the screw (attached to the bracket on the rear of the tension lever) through the adjusting window.

(6)Adjust so that the torque control stroke Dr1 can be obtained.

(7)Align N2 and N3 with the torque control spring capsule.

3. Final confirmation

(1)After final confirmation, temporarily set the load lever to N = N1, R = idling position.

(2)From this condition, increase speed to N = N4.

(3)Confirm that positive torque control stroke is Dr2.

----------

N1=500r/min N2=550+-40r/min N3=930+-50r/min N4=950r/min RF=10.6mm Dr1=0.8mm Dr2=0+0.3mm

----------

----------

N1=500r/min N2=550+-40r/min N3=930+-50r/min N4=950r/min RF=10.6mm Dr1=0.8mm Dr2=0+0.3mm

----------

Information:

USE FUEL CONSUMPTION, SERVICE HOURS OR TIME INTERVAL, WHICHEVER OCCURS FIRST. Performance of all lubrication and maintenance items in the Maintenance Schedule is the owners' responsibility.Daily

Walk-Around Inspection - Inspect for leaks and loose connections Engine Crankcase - Check oil level Cooling System - Check coolant level Air Cleaner Indicator - Test Air Starting Motor (If Equipped) - Check/fill oiler bowlEvery 18 950 L (5000 gal) of Fuel or 125 Hours*

Scheduled Oil Sampling (S O S) Analysis - Obtain sample Engine Oil & Filters - Change oil and oil filter(s) Fuel System - Drain water/sediment Cooling System - Test Crankcase Breathers - Clean Engine Valve Lash (At First Oil Change Only) - Check/AdjustEvery 37 900 L (10,000 gal) of Fuel or 250 Hours*

Batteries - Clean/Check electrolyte level Belts, Hoses and Clamps - Inspect/Replace if necessary Engine Air Cleaners - Replace Engine Speed Sensors - Inspect/clean magnetic pick-upEvery 151 600 L (40,000 gal) of Fuel or 1000 Hours*

Engine Protection Devices - Inspect for proper operation (Check at least twice per year) Engine Valve Lash - Check/Adjust Turbochargers - Inspect for proper operation Engine Mounts and Crankshaft Vibration Damper - Inspect/checkEvery 341 100 L (90,000 gal) of Fuel or 2250 Hours*

Connecting Rod Bearings - ReplaceEvery 454 800 L (120,000 gal) of Fuel or 3000 Hours or Two Years*

Cooling System - Clean/Flush/replace thermostats and gasketsOverhaul Every 511 650 L (135,000 gal) of Fuel or 5400 Hours*

To minimize downtime and provide you with the lowest cost and highest value, Caterpillar recommends that the engine be overhauled before failure by scheduling an overhaul with your Caterpillar dealer. Refer to the Overhaul section in this manual on page 85. Top End Overhaul After Failure Overhaul Starting Motor - Inspect for proper operation Alternator - Inspect for proper operation Engine Speed Sensors - Inspect/clean/test*First Perform Previous Service Hour Items Caterpillar suggests that fuel consumption be used as the preferred method of determining maintenance intervals. Fuel consumption/hours will vary depending on the proper application of your engine rating and adherence to recommended maintenance procedures.

Walk-Around Inspection - Inspect for leaks and loose connections Engine Crankcase - Check oil level Cooling System - Check coolant level Air Cleaner Indicator - Test Air Starting Motor (If Equipped) - Check/fill oiler bowlEvery 18 950 L (5000 gal) of Fuel or 125 Hours*

Scheduled Oil Sampling (S O S) Analysis - Obtain sample Engine Oil & Filters - Change oil and oil filter(s) Fuel System - Drain water/sediment Cooling System - Test Crankcase Breathers - Clean Engine Valve Lash (At First Oil Change Only) - Check/AdjustEvery 37 900 L (10,000 gal) of Fuel or 250 Hours*

Batteries - Clean/Check electrolyte level Belts, Hoses and Clamps - Inspect/Replace if necessary Engine Air Cleaners - Replace Engine Speed Sensors - Inspect/clean magnetic pick-upEvery 151 600 L (40,000 gal) of Fuel or 1000 Hours*

Engine Protection Devices - Inspect for proper operation (Check at least twice per year) Engine Valve Lash - Check/Adjust Turbochargers - Inspect for proper operation Engine Mounts and Crankshaft Vibration Damper - Inspect/checkEvery 341 100 L (90,000 gal) of Fuel or 2250 Hours*

Connecting Rod Bearings - ReplaceEvery 454 800 L (120,000 gal) of Fuel or 3000 Hours or Two Years*

Cooling System - Clean/Flush/replace thermostats and gasketsOverhaul Every 511 650 L (135,000 gal) of Fuel or 5400 Hours*

To minimize downtime and provide you with the lowest cost and highest value, Caterpillar recommends that the engine be overhauled before failure by scheduling an overhaul with your Caterpillar dealer. Refer to the Overhaul section in this manual on page 85. Top End Overhaul After Failure Overhaul Starting Motor - Inspect for proper operation Alternator - Inspect for proper operation Engine Speed Sensors - Inspect/clean/test*First Perform Previous Service Hour Items Caterpillar suggests that fuel consumption be used as the preferred method of determining maintenance intervals. Fuel consumption/hours will vary depending on the proper application of your engine rating and adherence to recommended maintenance procedures.