Information injection-pump assembly

ZEXEL

106671-3200

1066713200

HINO

220001591A

220001591a

Rating:

Cross reference number

ZEXEL

106671-3200

1066713200

HINO

220001591A

220001591a

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

134424-0620

Overflow valve opening pressure

kPa

162

147

177

Overflow valve opening pressure

kgf/cm2

1.65

1.5

1.8

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Left L

Left L

Injection timing adjustment

Direction of rotation (viewed from drive side)

Left L

Left L

Injection order

1-4-2-6-

3-5

Pre-stroke

mm

3.3

3.2

3.3

Beginning of injection position

Drive side NO.1

Drive side NO.1

Difference between angles 1

Cal 1-4 deg. 60 59.5 60.5

Cal 1-4 deg. 60 59.5 60.5

Difference between angles 2

Cyl.1-2 deg. 120 119.5 120.5

Cyl.1-2 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cal 1-3 deg. 240 239.5 240.5

Cal 1-3 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-5 deg. 300 299.5 300.5

Cal 1-5 deg. 300 299.5 300.5

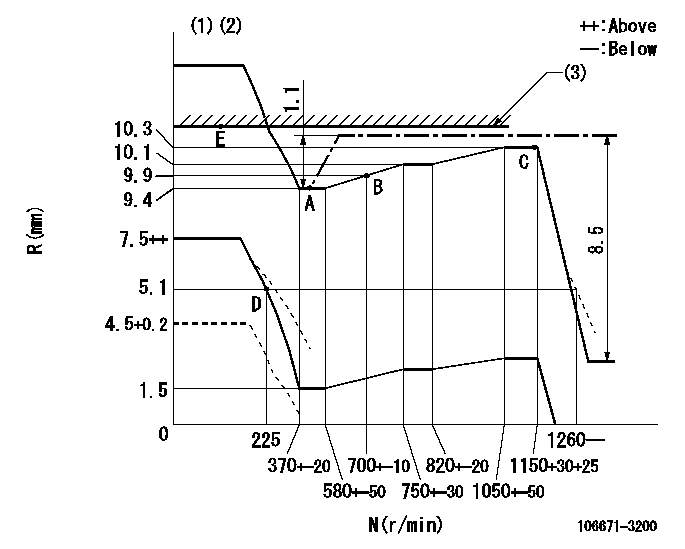

Injection quantity adjustment

Adjusting point

A

Rack position

9.4

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

112.5

109.5

115.5

Max. variation between cylinders

%

0

-4

4

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

9.9

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

127.7

125.7

129.7

Max. variation between cylinders

%

0

-2

2

Basic

*

Fixing the lever

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

10.3

Pump speed

r/min

1150

1150

1150

Average injection quantity

mm3/st.

137.7

134.7

140.7

Max. variation between cylinders

%

0

-4

4

Fixing the lever

*

Injection quantity adjustment_04

Adjusting point

D

Rack position

5.1+-0.5

Pump speed

r/min

225

225

225

Average injection quantity

mm3/st.

16

13

19

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Injection quantity adjustment_05

Adjusting point

E

Rack position

11+-0.5

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

125

125

145

Fixing the lever

*

Timer adjustment

Pump speed

r/min

700+-50

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

900

Advance angle

deg.

1.4

0.9

1.9

Timer adjustment_03

Pump speed

r/min

1150

Advance angle

deg.

4

3.5

4.5

Remarks

Finish

Finish

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Set the load lever's stop position so that R = aa (N = 0).

(2)Beginning of damper spring operation: DL

(3)RACK LIMIT

----------

aa=4.5+0.2mm DL=5.6-0.2mm

----------

----------

aa=4.5+0.2mm DL=5.6-0.2mm

----------

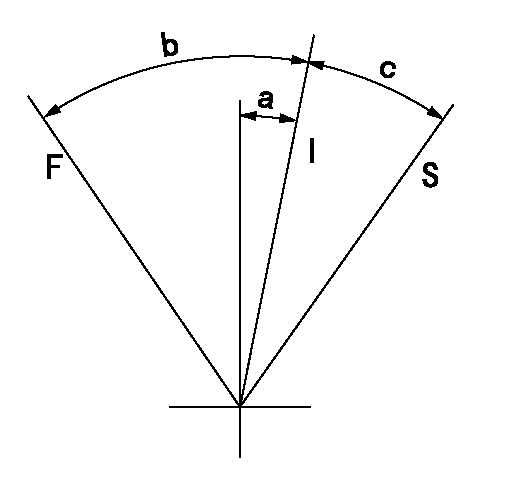

Speed control lever angle

F:Full speed

----------

----------

a=15deg+-5deg

----------

----------

a=15deg+-5deg

0000000901

F:Full load

I:Idle

S:Stop

----------

----------

a=10deg+-5deg b=27deg+-3deg c=14deg+-3deg

----------

----------

a=10deg+-5deg b=27deg+-3deg c=14deg+-3deg

0000001501 MICRO SWITCH

Switch adjustment

Adjust the bolt so that the lower lever position is obtained when the switch is turned ON.

(1)Speed N1

(2)Rack position Ra

----------

N1=325-25r/min Ra=5.1mm

----------

----------

N1=325-25r/min Ra=5.1mm

----------

Information:

Operation-Jacobs Brake

The Jacobs Engine Brake should not be used as a primary or service brake.Do not allow the engine to exceed 2300 rpm. However, engines equipped with a Jacobs Engine Brake should not be operated above 2100 rpm.

The Jacobs Engine Brake is an engine attachment that converts a diesel engine into an air compressor. Its function is to slow the vehicle and reduce brake wear.Operating Controls-Jacobs Brake

The Jacobs Engine Brake controls may include a dash mounted module or an ON/OFF switch and a three position switch with "Lo," "Med" and "Hi" depending on how many cylinders of braking desired. Refer to your truck manufacturer's Owner Manual for the type of operating controls that your vehicle is equipped with.The 3176 ECM monitors the clutch, brake, throttle position and engine rpm to determine when the Jacobs Brake can operate. It may take up to two seconds before Jacobs Brake activates.Since the Jacobs Engine Brake is most effective at rated engine rpm, gear selection is very important. Gearing down the vehicle, within the limits of rated engine rpm, makes the engine brake a more effective retarder. Maximum retarding occurs at higher engine rpm.Cruise Control (If Equipped) OFF

With the Cruise Control (CC) in the OFF position the Jacobs Engine Brake will function like any vehicle and engine that is not equipped with Cruise Control (CC).Cruise Control (If Equipped) ON

The driver must apply the service brake approximately two seconds and then release the service brake pedal. If the retarder "Latch" mode has been programmed, the retarder will continue to slow the vehicle. To release order activate the retarder, the clutch or throttle foot pedal must be depressed or the engine rpm drop to 950 rpm.When using "Coast" mode, the Jacobs Brake should activate within two seconds after the brake pedal is applied and remain on as long as the brake pedal is applied. At the time the brake pedal is applied, the Cruise Control (CC) will deactivate.For information on adjustment to Jacobs Brake slave piston lash, refer to PM Level 2-Engine Valve Lash. Refer to Jacobs Brake Troubleshooting Manual, Form SENR4251 for information regarding this auxiliary braking system.

The Jacobs Engine Brake should not be used as a primary or service brake.Do not allow the engine to exceed 2300 rpm. However, engines equipped with a Jacobs Engine Brake should not be operated above 2100 rpm.

The Jacobs Engine Brake is an engine attachment that converts a diesel engine into an air compressor. Its function is to slow the vehicle and reduce brake wear.Operating Controls-Jacobs Brake

The Jacobs Engine Brake controls may include a dash mounted module or an ON/OFF switch and a three position switch with "Lo," "Med" and "Hi" depending on how many cylinders of braking desired. Refer to your truck manufacturer's Owner Manual for the type of operating controls that your vehicle is equipped with.The 3176 ECM monitors the clutch, brake, throttle position and engine rpm to determine when the Jacobs Brake can operate. It may take up to two seconds before Jacobs Brake activates.Since the Jacobs Engine Brake is most effective at rated engine rpm, gear selection is very important. Gearing down the vehicle, within the limits of rated engine rpm, makes the engine brake a more effective retarder. Maximum retarding occurs at higher engine rpm.Cruise Control (If Equipped) OFF

With the Cruise Control (CC) in the OFF position the Jacobs Engine Brake will function like any vehicle and engine that is not equipped with Cruise Control (CC).Cruise Control (If Equipped) ON

The driver must apply the service brake approximately two seconds and then release the service brake pedal. If the retarder "Latch" mode has been programmed, the retarder will continue to slow the vehicle. To release order activate the retarder, the clutch or throttle foot pedal must be depressed or the engine rpm drop to 950 rpm.When using "Coast" mode, the Jacobs Brake should activate within two seconds after the brake pedal is applied and remain on as long as the brake pedal is applied. At the time the brake pedal is applied, the Cruise Control (CC) will deactivate.For information on adjustment to Jacobs Brake slave piston lash, refer to PM Level 2-Engine Valve Lash. Refer to Jacobs Brake Troubleshooting Manual, Form SENR4251 for information regarding this auxiliary braking system.