Information injection-pump assembly

BOSCH

9 400 610 071

9400610071

ZEXEL

106671-2941

1066712941

MITSUBISHI

ME059626

me059626

Rating:

Service parts 106671-2941 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

ME059621

12.

Open Pre:MPa(Kqf/cm2)

21.6{220}

15.

NOZZLE SET

Include in #1:

106671-2941

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 400 610 071

9400610071

ZEXEL

106671-2941

1066712941

MITSUBISHI

ME059626

me059626

Zexel num

Bosch num

Firm num

Name

106671-2941

9 400 610 071

ME059626 MITSUBISHI

INJECTION-PUMP ASSEMBLY

6D22T K 14CA INJECTION PUMP ASSY PE6P,6PD PE

6D22T K 14CA INJECTION PUMP ASSY PE6P,6PD PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131424-4620

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

4.8

4.75

4.85

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

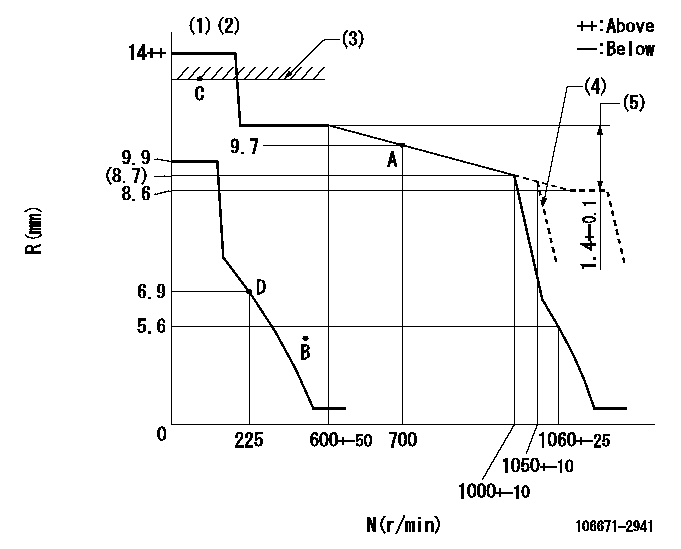

Injection quantity adjustment

Adjusting point

A

Rack position

9.7

Pump speed

r/min

700

700

700

Average injection quantity

mm3/st.

75

72

78

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

5.8+-0.5

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

15

12.4

17.6

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

13.9+-0.

5

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

133

113

153

Fixing the lever

*

Rack limit

*

Injection quantity adjustment_04

Adjusting point

D

Rack position

6.9+-0.5

Pump speed

r/min

225

225

225

Average injection quantity

mm3/st.

15

12.4

17.6

Fixing the rack

*

Remarks

(check)

(check)

Timer adjustment

Pump speed

r/min

650--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

600

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

900

Advance angle

deg.

1.6

1.1

2.1

Timer adjustment_04

Pump speed

r/min

1000

Advance angle

deg.

2.2

1.7

2.7

Timer adjustment_05

Pump speed

r/min

-

Advance angle

deg.

3

2.5

3.5

Remarks

Measure the actual speed, stop

Measure the actual speed, stop

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Torque spring does not operate.

(3)RACK LIMIT

(4)At shipping

(5)Rack difference between N = N1 and N = N2

----------

K=13 N1=1100r/min N2=500r/min

----------

----------

K=13 N1=1100r/min N2=500r/min

----------

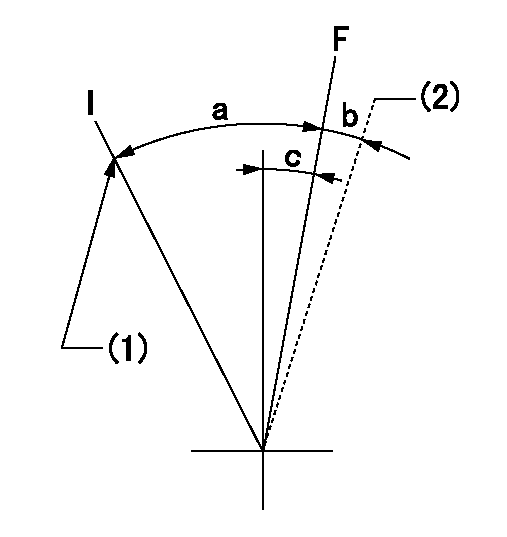

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

(2)At shipping

----------

----------

a=26deg+-5deg b=(2deg) c=5deg+-5deg

----------

----------

a=26deg+-5deg b=(2deg) c=5deg+-5deg

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=19deg+-5deg b=53deg+-5deg

----------

----------

a=19deg+-5deg b=53deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(7deg)

----------

----------

a=(7deg)

Information:

You must read and understand the warnings and instructions contained in the Safety section of this manual before performing any operation or maintenance procedures.This maintenance is to be performed at the interval specified in the Maintenance Schedule for the engine being maintained.Before proceeding with 125 Service Hour maintenance, first perform previous maintenance requirements.Clutch (If Equipped)

Refer to the Instruction Plate on your clutch for the correct lubrication information.Lubricate Shift Collar Bearings

Instruction PlateLubricate the shift collar fittings with one or two grease gun shots each with MPGL or 2S3230 grease. Do not over grease.Lubricate Shift Lever Bearings

Refer to the Instruction Plate on the clutch for lubrication information.Some earlier clutches have pilot bearing fittings that need lubrication, whereas the later clutches have pilot bearings that are sealed for life.Lubricate the clutch shift lever bearings, pilot bearing and main shaft bearing (if equipped). Lubricate one fitting on top-rear of housing. Lubricate one fitting at the end of shaft. Refer to Instruction Plate on your clutch for correct lubrication information.Check/Adjust

If the clutch is damaged to the point of burst failure, expelled pieces can cause personal injury to anyone in the immediate area. Proper safeguards must be followed to prevent accidents.Do NOT operate the engine with Instruction Plate cover removed from the clutch. Personal injury may result.

While engaging the clutch to pick up the load, check the clutch adjustment. The clutch should engage with a firm push of the lever and a distinct snap. If the engagement is "soft" or slow, adjust the clutch.When clutch lever is disengaged, the hand lever must fall behind the vertical position. If the clutch slips, overheats, or operating lever disengages, clutch adjustment is necessary.1. Stop the engine and remove the clutch inspection cover.2. Rotate the clutch manually until the lock pin (engaged in the locking ring) is visible.3. Pull the lock pin out and rotate the locking ring clockwise (CW) until the lock pin slips or pops into the next notch. Turn adjusting ring CW to increase engagement torque and CCW to decrease engagement torque.4. Test the clutch adjustment. To test the clutch adjustment, engage clutch with a torque wrench to turn adjusting ring so that 296 to 393 N m (218 to 289 lb ft)torque or 636 90 N (143 20 lb) force at 541 mm (21.3 inches) length on lever is required to engage the clutch. If torque is still low, rotate the locking ring (CW) until lock pin slips into next notch. If the adjustment is too tight, turn the locking ring back (CCW) one to the previous notch.5. Install cover plate after adjustment is completed.

Refer to the Instruction Plate on your clutch for the correct lubrication information.Lubricate Shift Collar Bearings

Instruction PlateLubricate the shift collar fittings with one or two grease gun shots each with MPGL or 2S3230 grease. Do not over grease.Lubricate Shift Lever Bearings

Refer to the Instruction Plate on the clutch for lubrication information.Some earlier clutches have pilot bearing fittings that need lubrication, whereas the later clutches have pilot bearings that are sealed for life.Lubricate the clutch shift lever bearings, pilot bearing and main shaft bearing (if equipped). Lubricate one fitting on top-rear of housing. Lubricate one fitting at the end of shaft. Refer to Instruction Plate on your clutch for correct lubrication information.Check/Adjust

If the clutch is damaged to the point of burst failure, expelled pieces can cause personal injury to anyone in the immediate area. Proper safeguards must be followed to prevent accidents.Do NOT operate the engine with Instruction Plate cover removed from the clutch. Personal injury may result.

While engaging the clutch to pick up the load, check the clutch adjustment. The clutch should engage with a firm push of the lever and a distinct snap. If the engagement is "soft" or slow, adjust the clutch.When clutch lever is disengaged, the hand lever must fall behind the vertical position. If the clutch slips, overheats, or operating lever disengages, clutch adjustment is necessary.1. Stop the engine and remove the clutch inspection cover.2. Rotate the clutch manually until the lock pin (engaged in the locking ring) is visible.3. Pull the lock pin out and rotate the locking ring clockwise (CW) until the lock pin slips or pops into the next notch. Turn adjusting ring CW to increase engagement torque and CCW to decrease engagement torque.4. Test the clutch adjustment. To test the clutch adjustment, engage clutch with a torque wrench to turn adjusting ring so that 296 to 393 N m (218 to 289 lb ft)torque or 636 90 N (143 20 lb) force at 541 mm (21.3 inches) length on lever is required to engage the clutch. If torque is still low, rotate the locking ring (CW) until lock pin slips into next notch. If the adjustment is too tight, turn the locking ring back (CCW) one to the previous notch.5. Install cover plate after adjustment is completed.

Have questions with 106671-2941?

Group cross 106671-2941 ZEXEL

Mitsubishi

Mitsubishi

106671-2941

9 400 610 071

ME059626

INJECTION-PUMP ASSEMBLY

6D22T

6D22T