Information injection-pump assembly

BOSCH

9 400 616 765

9400616765

ZEXEL

106671-2930

1066712930

MITSUBISHI

ME059627

me059627

Rating:

Service parts 106671-2930 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

ME059622

12.

Open Pre:MPa(Kqf/cm2)

21.6{220}

15.

NOZZLE SET

Include in #1:

106671-2930

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 400 616 765

9400616765

ZEXEL

106671-2930

1066712930

MITSUBISHI

ME059627

me059627

Zexel num

Bosch num

Firm num

Name

106671-2930

9 400 616 765

ME059627 MITSUBISHI

INJECTION-PUMP ASSEMBLY

6D22T * K 14CA INJECTION PUMP ASSY PE6P,6PD PE

6D22T * K 14CA INJECTION PUMP ASSY PE6P,6PD PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve

131424-4620

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

4.8

4.75

4.85

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

11.5

Pump speed

r/min

800

800

800

Average injection quantity

mm3/st.

142.4

139.4

145.4

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

5.5+-0.5

Pump speed

r/min

225

225

225

Average injection quantity

mm3/st.

16

13.4

18.6

Max. variation between cylinders

%

0

-15

15

Fixing the rack

*

Injection quantity adjustment_03

Adjusting point

C

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

130

125

135

Fixing the lever

*

Rack limit

*

Timer adjustment

Pump speed

r/min

1200

Advance angle

deg.

0.5

Remarks

Set beginning of governor operation at N = 1250 or more.

Set beginning of governor operation at N = 1250 or more.

Timer adjustment_02

Pump speed

r/min

-

Advance angle

deg.

2

2

2

Remarks

Measure the actual speed, stop

Measure the actual speed, stop

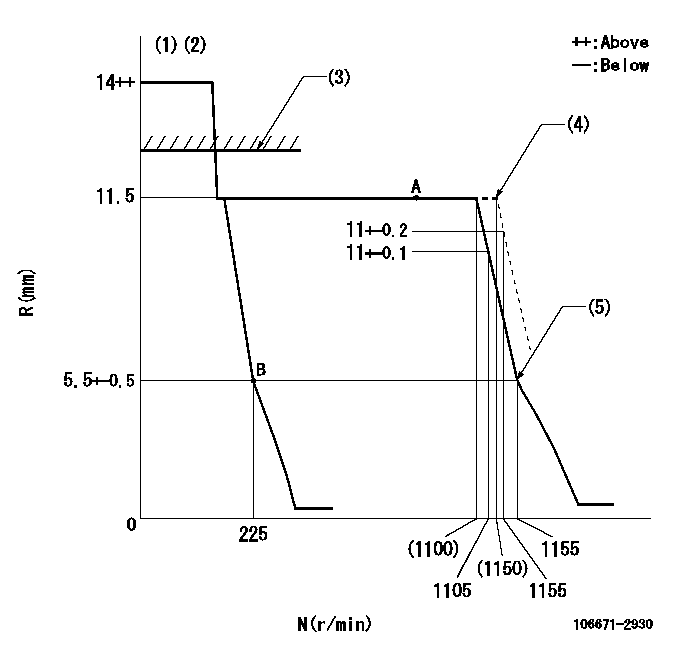

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Tolerance for racks not indicated: +-0.05mm.

(3)RACK LIMIT

(4)At shipping

(5)Idle sub spring setting: L1.

----------

K=5 L1=5.5+-0.1mm

----------

----------

K=5 L1=5.5+-0.1mm

----------

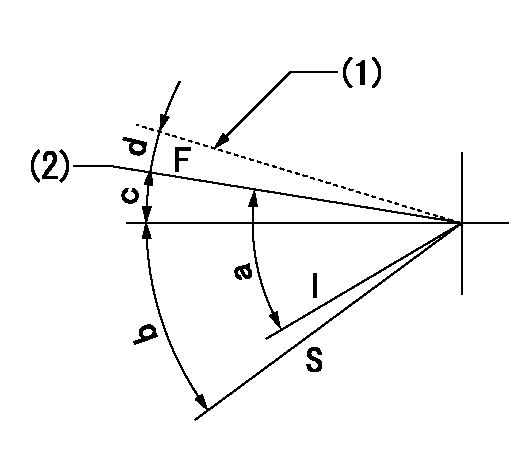

Speed control lever angle

F:Full speed

I:Idle

S:Stop

(1)At shipping

(2)Pump speed = aa

----------

aa=1100r/min

----------

a=30deg+-5deg b=32deg+-3deg c=7deg+-5deg d=(2deg)

----------

aa=1100r/min

----------

a=30deg+-5deg b=32deg+-3deg c=7deg+-5deg d=(2deg)

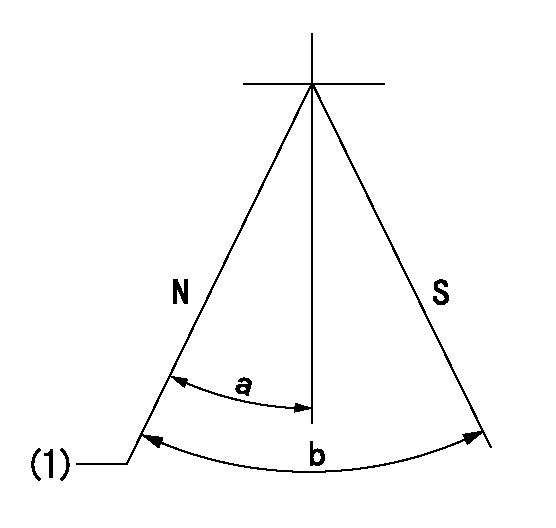

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Normal

----------

----------

a=19deg+-5deg b=53deg+-5deg

----------

----------

a=19deg+-5deg b=53deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(7deg)

----------

----------

a=(7deg)

Information:

Clean/Replace Standard Air Cleaner Elements

Never service the air cleaner with the engine running since this will allow dirt to enter the engine. Check the vessel air duct inlet piping for leaks. Make all repairs to air ducts and inlet piping immediately, as dirt and debris could enter the engine causing damage to the turbocharger and engine components.Clean or replace elements using these recommendations and/or your weather and operating conditions, or when required by the restriction indicator.

1. Remove air cleaner cover and element. Clean or discard used element. Refer to SEBF8062, Guideline for Reusable Parts-Cleaning and Inspection of Air Filters.2. Cover air inlet opening with a clean cloth or towel to prevent dirt and debris from entering the engine.3. Clean the inside of the air cleaner cover and body.Cleaning with Water, Air or Detergent

Do not clean the filter elements by bumping or tapping them. Engine damage could result.

Filter elements can be cleaned with pressure air - 205 kPa (30 psi) maximum, pressure water - 280 kPa (40 psi) maximum, or detergent washing. Direct air or water along the pleats inside and outside of filter element. The element can be washed in warm water and nonsudsing household detergent. Rinse inside and outside the pleats and air dry fully.Inspect the filter elements after cleaning. Do not use a filter element with damaged pleats, gaskets or seals. Wrap and store the clean filter elements in a clean, dry place. Remove cloth from air inlet opening and install clean element while noting arrows indicating air flow on the side of the element. Install cover and reset service indicator.Cleaning Marine Air Cleaner Elements

1. Remove the air cleaner (1) and vacuum limiter element(s) (2). Tap the elements gently to dislodge any large particles. Gently brush the filter elements with a soft bristle brush.

NEVER use gasoline, steam, caustic or unapproved detergents or parts cleaning solvents. Never use high pressure water or air for cleaning. Using any of these liquids or methods will cause filter element damage.

Use the 102-9720 (U.S.) or 102-9721 (non-U.S.) Cleaning Kit exclusively. The kit contains detergent and oil products specifically for the maintenance of the air and vacuum limiter filter elements.2. Spray cleaning solution on the elements and allow to soak for ten minutes. Rinse the element(s) with low pressure water (tap water is acceptable) from the inside (clean side) out (dirty side) to remove dirt and debris and not drive them into element material.3. Shake off excess water and dry filter elements naturally and thoroughly. Inspect housing and clamp. Replace if necessary.

DO NOT dry elements with compressed air, open flame or heat dryers. Excess heat will shrink cotton fiber and compressed air may blow holes in material.

4. Inspect filter elements after cleaning for tears and/or holes in filter material. Do not re-use damaged filters, replace if necessary.

NEVER use automatic transmission fluid, motor oil, diesel fuel or lightweight oils to re-oil filter element. Do NOT install and operate engine with element dry.

5. Always re-oil filter elements before installing. Squeeze oil down into bottom

Never service the air cleaner with the engine running since this will allow dirt to enter the engine. Check the vessel air duct inlet piping for leaks. Make all repairs to air ducts and inlet piping immediately, as dirt and debris could enter the engine causing damage to the turbocharger and engine components.Clean or replace elements using these recommendations and/or your weather and operating conditions, or when required by the restriction indicator.

1. Remove air cleaner cover and element. Clean or discard used element. Refer to SEBF8062, Guideline for Reusable Parts-Cleaning and Inspection of Air Filters.2. Cover air inlet opening with a clean cloth or towel to prevent dirt and debris from entering the engine.3. Clean the inside of the air cleaner cover and body.Cleaning with Water, Air or Detergent

Do not clean the filter elements by bumping or tapping them. Engine damage could result.

Filter elements can be cleaned with pressure air - 205 kPa (30 psi) maximum, pressure water - 280 kPa (40 psi) maximum, or detergent washing. Direct air or water along the pleats inside and outside of filter element. The element can be washed in warm water and nonsudsing household detergent. Rinse inside and outside the pleats and air dry fully.Inspect the filter elements after cleaning. Do not use a filter element with damaged pleats, gaskets or seals. Wrap and store the clean filter elements in a clean, dry place. Remove cloth from air inlet opening and install clean element while noting arrows indicating air flow on the side of the element. Install cover and reset service indicator.Cleaning Marine Air Cleaner Elements

1. Remove the air cleaner (1) and vacuum limiter element(s) (2). Tap the elements gently to dislodge any large particles. Gently brush the filter elements with a soft bristle brush.

NEVER use gasoline, steam, caustic or unapproved detergents or parts cleaning solvents. Never use high pressure water or air for cleaning. Using any of these liquids or methods will cause filter element damage.

Use the 102-9720 (U.S.) or 102-9721 (non-U.S.) Cleaning Kit exclusively. The kit contains detergent and oil products specifically for the maintenance of the air and vacuum limiter filter elements.2. Spray cleaning solution on the elements and allow to soak for ten minutes. Rinse the element(s) with low pressure water (tap water is acceptable) from the inside (clean side) out (dirty side) to remove dirt and debris and not drive them into element material.3. Shake off excess water and dry filter elements naturally and thoroughly. Inspect housing and clamp. Replace if necessary.

DO NOT dry elements with compressed air, open flame or heat dryers. Excess heat will shrink cotton fiber and compressed air may blow holes in material.

4. Inspect filter elements after cleaning for tears and/or holes in filter material. Do not re-use damaged filters, replace if necessary.

NEVER use automatic transmission fluid, motor oil, diesel fuel or lightweight oils to re-oil filter element. Do NOT install and operate engine with element dry.

5. Always re-oil filter elements before installing. Squeeze oil down into bottom

Have questions with 106671-2930?

Group cross 106671-2930 ZEXEL

Mitsubishi

Mitsubishi

106671-2930

9 400 616 765

ME059627

INJECTION-PUMP ASSEMBLY

6D22T

6D22T