Information injection-pump assembly

BOSCH

9 400 610 323

9400610323

ZEXEL

106671-2684

1066712684

MITSUBISHI-HEAV

3626520182

3626520182

Rating:

Service parts 106671-2684 INJECTION-PUMP ASSEMBLY:

1.

_

7.

COUPLING PLATE

8.

_

9.

_

11.

Nozzle and Holder

36261-11070

12.

Open Pre:MPa(Kqf/cm2)

21.6{220}

15.

NOZZLE SET

Include in #1:

106671-2684

as INJECTION-PUMP ASSEMBLY

Cross reference number

BOSCH

9 400 610 323

9400610323

ZEXEL

106671-2684

1066712684

MITSUBISHI-HEAV

3626520182

3626520182

Zexel num

Bosch num

Firm num

Name

9 400 610 323

3626520182 MITSUBISHI-HEAV

INJECTION-PUMP ASSEMBLY

S6B * K 14CA PE6P,6PD PE

S6B * K 14CA PE6P,6PD PE

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8130

Bosch type code

EFEP215A

Nozzle

105780-0050

Bosch type code

DN6TD119NP1T

Nozzle holder

105780-2090

Bosch type code

EFEP215

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve opening pressure

kPa

157

123

191

Overflow valve opening pressure

kgf/cm2

1.6

1.25

1.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

3.7

3.65

3.75

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

Injection quantity adjustment

Adjusting point

A

Rack position

15.1

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

321.2

314.2

328.2

Max. variation between cylinders

%

0

-3

3

Basic

*

Fixing the lever

*

Injection quantity adjustment_02

Adjusting point

B

Rack position

7.5+-0.5

Pump speed

r/min

250

250

250

Average injection quantity

mm3/st.

30.5

27.5

33.5

Max. variation between cylinders

%

0

-10

10

Fixing the rack

*

Timer adjustment

Pump speed

r/min

450--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

400

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

600

Advance angle

deg.

1

0.5

1.5

Timer adjustment_04

Pump speed

r/min

700

Advance angle

deg.

1.5

1

2

Remarks

Finish

Finish

Test data Ex:

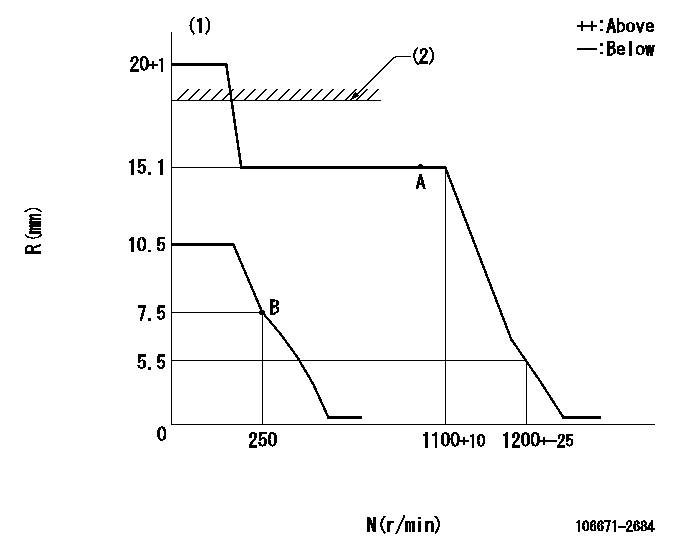

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Target notch: K

(2)Fully back off the screw and set.

----------

K=16

----------

----------

K=16

----------

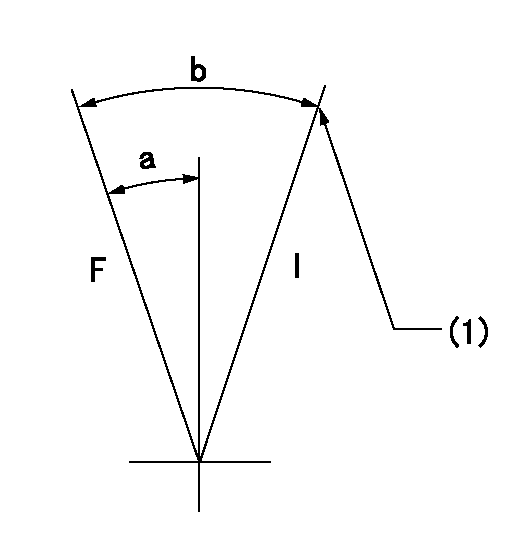

Speed control lever angle

F:Full speed

I:Idle

(1)Stopper bolt setting

----------

----------

a=14deg+-5deg b=37deg+-5deg

----------

----------

a=14deg+-5deg b=37deg+-5deg

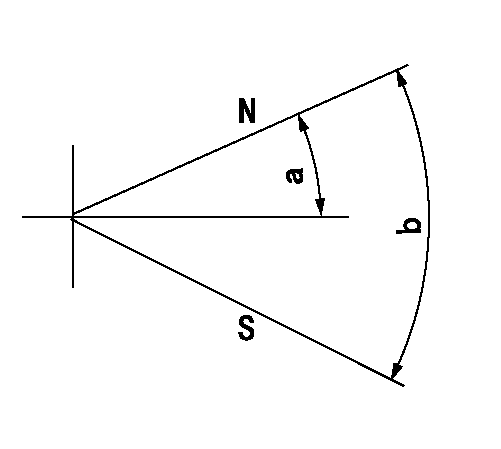

Stop lever angle

N:Pump normal

S:Stop the pump.

----------

----------

a=19deg+-5deg b=53deg+-5deg

----------

----------

a=19deg+-5deg b=53deg+-5deg

Timing setting

(1)Pump vertical direction

(2)Coupling's key groove position at No 1 cylinder's beginning of injection

(3)-

(4)-

----------

----------

a=(100deg)

----------

----------

a=(100deg)

Information:

PRESSURIZING THE SYSTEMIf the pressure isn't maintained, overflow loss can occur as cooling system temperature rises. Do not remove the cap while the system is at operating temperature. Check coolant level only when cold.If the system does not hold pressure, find the leak.Carefully inspect the radiator cap, seals, sealing surfaces and the top tank filler neck surface for damage.

RADIATOR CAPTesting The Temperature Gauge

Remember that boiling point temperature and pressure go hand-in-hand and neither one can be tested logically without considering the other. For example, the effect of pressurization and altitude on the boiling point of water is shown in the chart. If overheating and loss of coolant is a problem, a pressure loss in the system could be the cause. If an overheating condition is indicated on the temperature gauge and loss of coolant is not evident, check the accuracy of the temperature gauge. Make this check by installing a thermometer with a suitable bushing into the cylinder head.Start the engine. Partially cover the radiator to reduce air flow and cooling. The reading on the instrument panel gauge should agree with the reading on the thermometer.

Use CAUTION when working around moving parts with the engine running.

CHECKING COOLANT TEMPERATURE WITH THERMOMETERTemperature Regulators

There is a temperature regulator located at the front of each cylinder head.The opening temperature of the regulator (bench test in antmospheric pressure) should be 180 2°F (82 2°C). The regulator should be fully open at approximately 197°F (92°C). 1. Remove the regulator from the housing.2. Submerge the regulator and a thermometer in a pan of water as shown.3. Apply heat to the pan and stir the water to maintain uniformity.4. Observe the opening temperature of the regulator.If the regulator does not operate correctly, install a new one. Cooling System Hoses

Inspect all coolant hoses annually and replace if they show signs of cracking or leaking. Periodically replace all hoses, as it is many times difficult to determine the condition of a water hose by visual inspection and feel. Coolant hoses are expendable items and periodic replacement is considered good maintenance practice.Air, Gases And Steam In The System

Incomplete or improper filling is a major cause of air in the cooling system. Also, leaks in various components such as the aftercooler, and hoses allow air to enter the cooling system, especially on the inlet side of the water pump.Air in the system produces foaming or aeration and affects water pump performance. The air bubbles insulate various parts of the engine from the coolant, and hot spots form. As the air bubbles circulate or break up, coolant contacts the hot surfaces, creating steam. The steam pockets have basically the same effect as air bubbles, accelerating the formation of more steam. Consequently, coolant discharges through the overflow.Exhaust gas leakage into the system causes similar conditions. Exhaust gas can enter through internal cracks or defective cylinder head gaskets.Most of the causes can be checked by a visual inspection, while others require disassembly or a simple test.Air in the cooling system is