Information injection-pump assembly

ZEXEL

106671-2610

1066712610

Rating:

Cross reference number

ZEXEL

106671-2610

1066712610

Zexel num

Bosch num

Firm num

Name

Calibration Data:

Adjustment conditions

Test oil

1404 Test oil ISO4113 or {SAEJ967d}

1404 Test oil ISO4113 or {SAEJ967d}

Test oil temperature

degC

40

40

45

Nozzle and nozzle holder

105780-8140

Bosch type code

EF8511/9A

Nozzle

105780-0000

Bosch type code

DN12SD12T

Nozzle holder

105780-2080

Bosch type code

EF8511/9

Opening pressure

MPa

17.2

Opening pressure

kgf/cm2

175

Injection pipe

Outer diameter - inner diameter - length (mm) mm 8-3-600

Outer diameter - inner diameter - length (mm) mm 8-3-600

Overflow valve opening pressure

kPa

255

221

289

Overflow valve opening pressure

kgf/cm2

2.6

2.25

2.95

Tester oil delivery pressure

kPa

157

157

157

Tester oil delivery pressure

kgf/cm2

1.6

1.6

1.6

Direction of rotation (viewed from drive side)

Right R

Right R

Injection timing adjustment

Direction of rotation (viewed from drive side)

Right R

Right R

Injection order

1-5-3-6-

2-4

Pre-stroke

mm

4.8

4.75

4.85

Beginning of injection position

Governor side NO.1

Governor side NO.1

Difference between angles 1

Cal 1-5 deg. 60 59.5 60.5

Cal 1-5 deg. 60 59.5 60.5

Difference between angles 2

Cal 1-3 deg. 120 119.5 120.5

Cal 1-3 deg. 120 119.5 120.5

Difference between angles 3

Cal 1-6 deg. 180 179.5 180.5

Cal 1-6 deg. 180 179.5 180.5

Difference between angles 4

Cyl.1-2 deg. 240 239.5 240.5

Cyl.1-2 deg. 240 239.5 240.5

Difference between angles 5

Cal 1-4 deg. 300 299.5 300.5

Cal 1-4 deg. 300 299.5 300.5

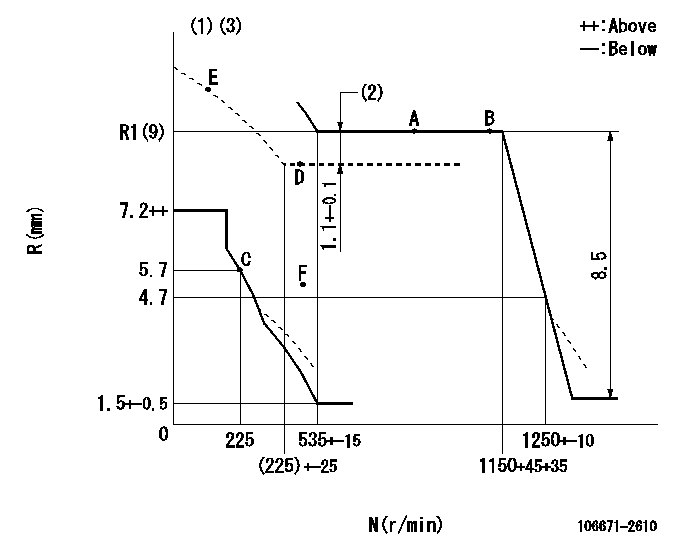

Injection quantity adjustment

Adjusting point

-

Rack position

9

Pump speed

r/min

600

600

600

Each cylinder's injection qty

mm3/st.

136

133

139

Basic

*

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_02

Adjusting point

F

Rack position

5+-0.5

Pump speed

r/min

500

500

500

Each cylinder's injection qty

mm3/st.

16.5

14

19

Fixing the rack

*

Standard for adjustment of the maximum variation between cylinders

*

Injection quantity adjustment_03

Adjusting point

A

Rack position

R1(9)

Pump speed

r/min

600

600

600

Average injection quantity

mm3/st.

136

135

137

Fixing the lever

*

Boost pressure

kPa

60

60

Boost pressure

mmHg

460

460

Injection quantity adjustment_04

Adjusting point

B

Rack position

R1(9)

Pump speed

r/min

1100

1100

1100

Average injection quantity

mm3/st.

148

144.8

151.2

Difference in delivery

mm3/st.

6.4

6.4

6.4

Fixing the lever

*

Boost pressure

kPa

60

60

Boost pressure

mmHg

460

460

Injection quantity adjustment_05

Adjusting point

D

Rack position

7.9+-0.5

Pump speed

r/min

500

500

500

Average injection quantity

mm3/st.

107.5

104.3

110.7

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Injection quantity adjustment_06

Adjusting point

C

Rack position

5.7+-0.5

Pump speed

r/min

225

225

225

Each cylinder's injection qty

mm3/st.

16.5

14

19

Fixing the rack

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Remarks

(check)

(check)

Injection quantity adjustment_07

Adjusting point

E

Rack position

-

Pump speed

r/min

100

100

100

Average injection quantity

mm3/st.

105

65

145

Fixing the lever

*

Boost pressure

kPa

0

0

0

Boost pressure

mmHg

0

0

0

Boost compensator adjustment

Pump speed

r/min

600

600

600

Rack position

7.9

Boost pressure

kPa

28

28

28

Boost pressure

mmHg

210

210

210

Boost compensator adjustment_02

Pump speed

r/min

600

600

600

Rack position

8.65

Boost pressure

kPa

37.3

36

38.6

Boost pressure

mmHg

280

270

290

Boost compensator adjustment_03

Pump speed

r/min

600

600

600

Rack position

R1(9)

Boost pressure

kPa

48

41.3

54.7

Boost pressure

mmHg

360

310

410

Timer adjustment

Pump speed

r/min

950--

Advance angle

deg.

0

0

0

Remarks

Start

Start

Timer adjustment_02

Pump speed

r/min

900

Advance angle

deg.

0.5

Timer adjustment_03

Pump speed

r/min

1000

Advance angle

deg.

2.5

2

3

Remarks

Finish

Finish

Test data Ex:

Governor adjustment

N:Pump speed

R:Rack position (mm)

(1)Beginning of damper spring operation: DL

(2)Boost compensator stroke

(3)Boost compensator cancel stroke: BSL

----------

DL=4.5-0.2mm BSL=2.2mm

----------

----------

DL=4.5-0.2mm BSL=2.2mm

----------

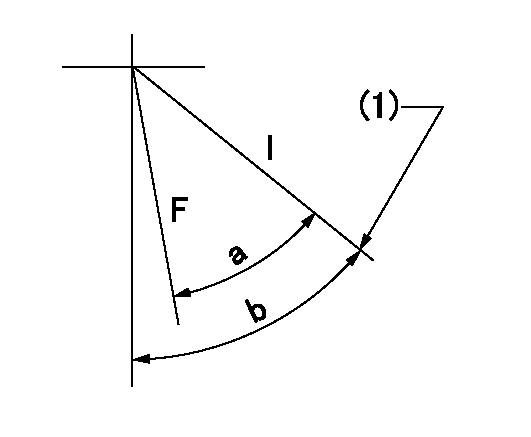

Speed control lever angle

F:Full speed

----------

----------

a=18deg+-5deg

----------

----------

a=18deg+-5deg

0000000901

F:Full load

I:Idle

(1)Stopper bolt setting

----------

----------

a=28deg+-3deg b=29.5deg+-5deg

----------

----------

a=28deg+-3deg b=29.5deg+-5deg

Stop lever angle

N:Pump normal

S:Stop the pump.

(1)Rack position = aa

(2)Stopper bolt setting

(3)Rack position bb

(4)Free (at delivery)

----------

aa=4.1-0.5mm bb=13.3mm

----------

a=26deg+-5deg b=(38deg) c=0deg+7deg+5deg

----------

aa=4.1-0.5mm bb=13.3mm

----------

a=26deg+-5deg b=(38deg) c=0deg+7deg+5deg

0000001501 MICRO SWITCH

Adjustment of the micro-switch

Adjust the bolt to obtain the following lever position when the micro-switch is ON.

(1)Speed N1

(2)Rack position Ra

----------

N1=325+-5r/min Ra=5.4mm

----------

----------

N1=325+-5r/min Ra=5.4mm

----------

Information:

1. Remove suction bell (3) and tubes, oil supply tube (2) and Brake Saver oil supply tube (1) from the engine block and oil pump. 2. Remove three bolts (5) and oil pump (4) from the engine. The following steps are for installation of the oil pump.3. Put oil pump (4) in position on the engine. Make sure the oil pump gear is engaged with the crankshaft gear, and install three bolts (5) that hold the oil pump.4. Put clean engine oil on the O-ring seals on the oil tubes.5. Install suction bell (3) and tubes, oil supply tube (2) and the BrakeSaver oil supply tube (1).End By:a. install oil pan (BrakeSaver)Disassemble Oil Pump (BrakeSaver)

Start By:a. remove oil pump (Brake Saver) 1. Remove the bolt and washer that hold drive gear (1) on the shaft.2. Use tooling (A) to remove drive gear (1) from the shaft. Remove the key from the shaft. Put alignment marks on the pump bodies so they can be assembled in the correct position. 3. Remove retainer (3) for the bypass valve. Remove the spring and bypass valve.4. Remove bolts (4) that hold pump body (2) to the main pump body. Remove pump body (2).5. Use tooling (B) to remove the bearings from pump body (2). 6. Remove gears (7). Put identification marks on the gears so they can be assembled in the same position.7. Remove spacer (6) from main oil pump body (5). Use tooling (B) to remove the bearings from spacer (6).8. Remove the gears from main oil pump body (5). 9. Use tooling (B) to remove the bearings from the main oil pump body.Assemble Oil Pump (BrakeSaver)

1. Use tooling (B) to install bearings (8) until they are even with the outside surface of main oil pump body (5). Install bearings (8) so the joints in the bearings are 30 ° 15 ° from the center line

Start By:a. remove oil pump (Brake Saver) 1. Remove the bolt and washer that hold drive gear (1) on the shaft.2. Use tooling (A) to remove drive gear (1) from the shaft. Remove the key from the shaft. Put alignment marks on the pump bodies so they can be assembled in the correct position. 3. Remove retainer (3) for the bypass valve. Remove the spring and bypass valve.4. Remove bolts (4) that hold pump body (2) to the main pump body. Remove pump body (2).5. Use tooling (B) to remove the bearings from pump body (2). 6. Remove gears (7). Put identification marks on the gears so they can be assembled in the same position.7. Remove spacer (6) from main oil pump body (5). Use tooling (B) to remove the bearings from spacer (6).8. Remove the gears from main oil pump body (5). 9. Use tooling (B) to remove the bearings from the main oil pump body.Assemble Oil Pump (BrakeSaver)

1. Use tooling (B) to install bearings (8) until they are even with the outside surface of main oil pump body (5). Install bearings (8) so the joints in the bearings are 30 ° 15 ° from the center line